Engines are a type of machinery designed to convert different forms of energy into mechanical work. This is the energy that your car uses to move forward. This can look very confusing. After all, it is a bunch of metals and wires put together. But this complex machinery is responsible for your car moving forward smoothly every day. One type of engine that goes far back in time is the rotary engine. Even though these engines were quite the hype back then, are rotary engines reliable in the present world?

Complex machinery like engines does not come in one specific type. There are various types of car engines. Each of them comprises of different characteristics. Different engines use different types of energy to generate power. The most commonly used type of engine is the thermal engine. These engines convert heat energy into work.

Among the types of thermal engines, people are most familiar with internal combustion engines. These engines are broadly used in vehicles, boats, airplanes, and trains. There exist different types of internal combustion engines. And one of the most well-known examples of an internal combustion engine would be the rotary engine.

In this article, we will talk about rotary engines. We will get a clear idea of their history and their current reliability. Stick around till the end to gain proper and precisely detailed knowledge on rotary engines. We shall also discuss if they are the best choice for your car today.

- What Are They?

- Components

- Basic Functions

- Advantages

- Disadvantages

- Present Day

- Rotary-Powered Cars

- Research And Development

What Are Rotary Engines?

As the name suggests, a rotary is the type of engine which consists of certain rotating parts that generate energy. Rotary engines have been in the business for a very long time. These engines had their era of prevalence. They used to be considered one of the most efficient and systematic engines in the marketplace.

But the question is if these engines are still equally reliable today? Times have changed. And technology has significantly brought in improvements in every field of business. It is true that for a brief period, rotary engines were widely used in vehicles. But are rotary engines reliable even today? Different engineers have different opinions on this topic.

Rotary engines: Past

Rotary engines were invented by German engineer Felix Wankel. That is why rotary engines are also widely known as Wankel engines. The most mentionable use of rotary engine vehicles was during the First World War. These engines were used as an alternative to inline engines during that period.

Eventually, in the early 1920s, the benefit of using rotary engines came to a halt. The internal combustion type engine got replaced by piston-type engines around that era. The main reasons behind this replacement were the affordability of the engine and its contribution to our environment. Nevertheless, rotary engines were used widely across the globe for the period that it was prevalent.

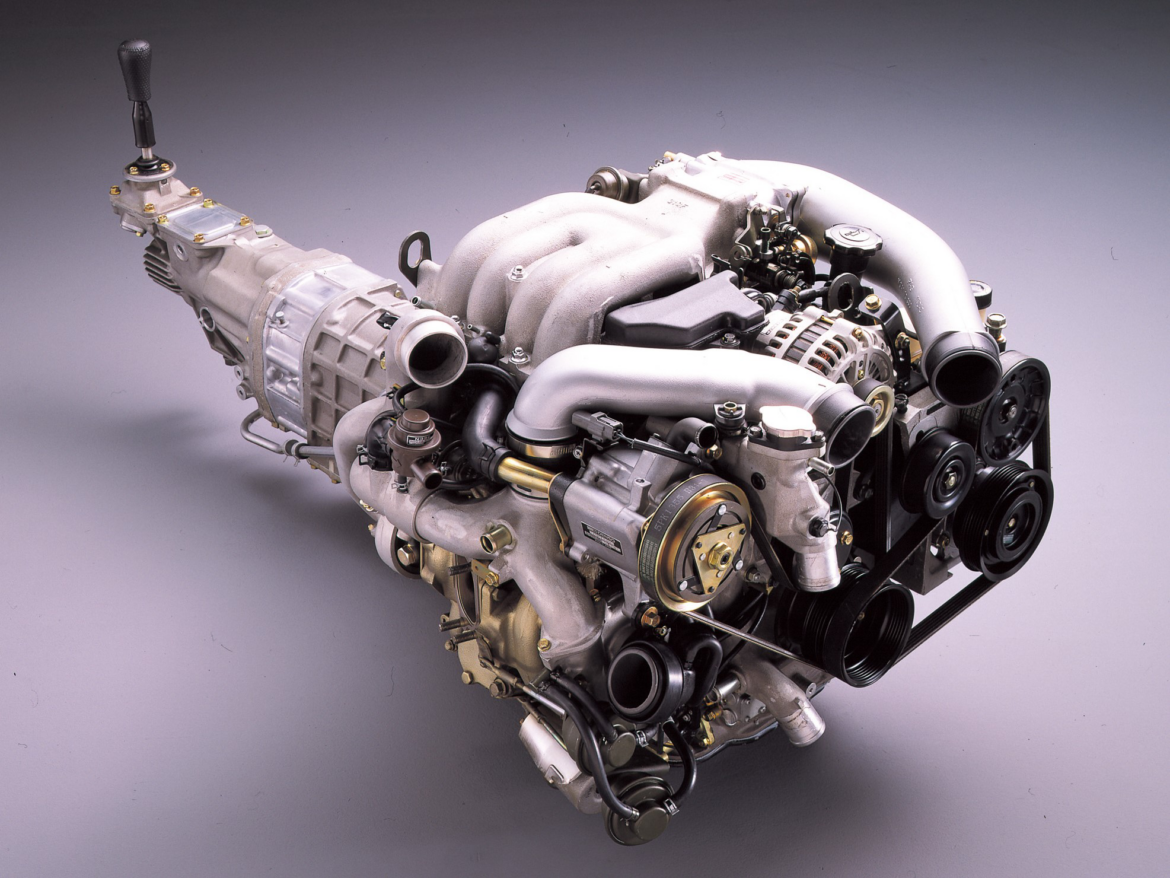

Components

The engines that are the current talk of the market have more complex components in comparison to the rotary ones. A basic rotary engine can be categorized into three separate sections.

1. Rotor

A rotor is a triangle-shaped bolt with curvature sides. It moves in a circular pathway along its housing area. It orbits around the main central shaft while spinning by itself. The rotor is designed in a way that it can let in larger volumes of gas inside the housing chamber. Due to this ability, the performance becomes much more efficient.

2. Housing Chamber

The housing chamber of the engine is where the main functions take place. This chamber is oval-shaped. Due to such shaping, it complements the rotor’s movement perfectly. The pointy edges of the rotor stay in constant touch with the inside surface of the housing.

3. Exhaust Port

The exhaust port is mainly the pathway from where the expanded gases are released. This port works as the output portion of the engine.

Basic Functions

A rotary engine works in a completely different manner when compared to a conventional piston engine from today’s market. The rotary engine focuses on four main activities. All these four actions take place in the only particular housing of the engine. It performs simultaneously, getting one activity done after another fluently.

The cycle following which the rotor engine functions is called its combustion cycle. The four main activities that happen during this combustion cycle are responsible for the overall output you can get from the engine. We will talk about this cycle now.

1. Intake

Intake is the first stage of how a rotary engine works. The intake stage begins when one sharp corner of the rotor crosses the intake port. Due to this, some air gets drawn inside the engine. This air is then eventually led inside the housing to a different section.

2. Compression

The second stage that happens in a rotary engine is known as compression. In this stage, air passed from the intake port enters the housing. As it enters, three tight gas sections get formed inside. The gas sections inside get expanded and contracted as the rotor moves in a circular pathway. The mechanics behind this is the shape of the rotor. As the sections decrease in size, the air gets compressed.

3. Ignition

Ignition is the third stage of the functioning of a rotary engine. In this stage, the compressed gas gets ignited. This ignition generates pressure. This vast amount of pressure is why the rotor gets forced to expand. Ignition is the stage where the actual energy forms. The gas thus expands in the chamber through ignition.

4. Exhaust

The expanded gas stays inside the chamber until its sharp end does not cross the exhaust port. When the end passes the port, the gas gets emitted from the housing through it. Exhaustion is the fourth and final stage of how a rotary engine functions.

This cycle keeps repeating simultaneously, generating more and more power. All the stages keep happening at the same time, making the rotary engine efficient and systematic. But, are rotary engines reliable because of such functionality?

Are Rotary Engines Reliable: Advantages

Rotary engines are not in the market anymore. But for the time they existed, they existed for all the right reasons. People loved using rotary engines more than any other type. The advantages of the engine during that period were remarkable ones.

Less Number Of Moving Parts

As mentioned before, the rotary engine main comprises only three different parts. This property makes the engine appear less complex and complicated than most other ones prevalent in today’s market. The ones used most widely these days, consisting of 30 to 40 different parts, make their functionality complex. While on the other hand, rotary engines are simple within their components.

Smoother Functionality

The rotary engine performs its four basic activities simultaneously and in one flow. It does not have any complicated system. For this reason, the combustion cycle of a rotary engine is way smoother than most others. There are engines in the market that frequently change positions while functioning. Those engines require far more attention and service.

Another reason the rotary engine is known to have smoother functionality is because of its temperature control ability. There are counterweights present on the outside of rotary engine housing. These counterweights can skillfully reduce vibration and deliver a smooth performance from the engine.

Slow And Steady

The inner activities that take place in a rotary engine are much slower in comparison to the piston engines these days. The piston engines require simultaneous upward and downward movement with an adequate speed. As a result, we can understand that the inner activities in a piston engine happen under a lot of pressure.

While on the other hand, rotary engines function slowly and function in one specific direction. The piston engines require much more attention and maintenance in this respect.

Smaller In Size

Since it is formed of only two main parts, a rotary engine is much smaller and compact in its design. Its physical size is much smaller than a conventional piston engine. This sizing gives the rotary engine advantage of being carried around easily. It also helps in the easy packaging of the machinery.

Self-Cooling Abilities

Due to the combustion cycle in a rotary engine, the airflow keeps coming in circles. This flow of air does not allow the machine to heat up fast. Cooling is an important characteristic when it comes to an engine. This property lets the engine last longer and not malfunction easily. That is why the cooling ability of a rotary engine is a notable advantage for its users.

As we can see, the rotary engine has some quality advantages. But then why are we still questioning are rotary engines reliable or not? That is because of some of the drawbacks of the machinery. Even though all the characteristics and properties seem beneficial, some in-depth disadvantages have led to the engine not being that prevalent anymore.

Disadvantages Of A Rotary Engine

Some major disadvantages of the rotary engine are discussed below. These are the main reason behind the engine’s ultimate nonexistence over time.

Low Thermal Efficiency

Rotary engines consume a good deal of fuel. This fuel consumption happens because of its low compression ratio. Like mentioned earlier, the engine encompasses a long and thin combustion chamber. Due to this, the fuel-burning process is comparatively slow.

At times, un-burnt fuel reaches the exhaust pathway of the engine. Engineers have attempted to fix this issue by using spark plugs. But the effort went in vain. Even with the help of two spark plugs, the combustion was left incomplete at times. Therefore, it results in an overall low thermal efficiency rate for the engine.

Sealing Issue

Rotary engines require using a seal in the center shaft and the sharp edges of the rotor. The seal at the tip edges is called an apex seal of the engine. The apex seal comes in direct contact with the inner walls of the housing. This seal is essential because the engine requires the tips of the rotor to touch the internal housing walls.

Without the seal, the combustion rate of the engine would be affected negatively. So, engine oil is applied to avoid friction between the seals and the housing. For this purpose, the rotary engine requires a good amount of engine oil.

Short Lifespan

Rotary engines are not expected to perform in their initial efficient manner for a very long time. The engine can have frequent issues with its sealing and emission control. As a result, potential buyers stay aware before purchasing a rotary one. If the engine did not have several complications with its functionality, its life span would be longer.

Requirement Of Maintenance

The engine only has two main parts. But due to having low thermal efficiency, it requires attention and maintenance very frequently. It needs to be kept clean and neat.

The main reason behind the requirement of such rapid management is the leaking of fuel that we mentioned earlier. Cleaning the engine and keeping it in check is not that much of a difficult task. But the activity can still feel like a hassle at times.

Higher Manufacturing Costs

Back in time, rotary engines were in great demand. Eventually, the piston engines made their place in the market. For this reason, the production rate of rotary engines is nonexistent these days. Due to such a low production rate, the manufacturing costs of the engine have gone much higher.

As mentioned earlier, rotary engines require good management and attention. But the higher maintenance costs of the engine are a huge drawback for many people. Besides, the availability of engineers certified to fix rotary engine issues is also extremely scarce.

Not Environment Friendly

The rotary engine is not an environment-friendly engine at all. Because of having a high pollution rate, the engine fails to meet the US emission regulations. Due to the massive fuel consumption, the amount of overall carbon-dioxide emission from the engine works as a drawback.

And in fact, ours is the generation working towards better creating and raising awareness for a green environment every day. In such circumstances, rotary engines cannot be prioritized like piston engines.

These are some of the huge drawbacks of the rotary engine. These disadvantages can make anyone question, are rotary engines reliable today after all? They sure had their time back in the days, but should they still be considered a potential purchase?

Now, we shall look into the present status of rotary engines in our market. Which vehicles are still using it? How are experts exactly eyeing the future of rotary engines? These are some questions to be answered to understand- are rotary engines reliable in today’s time or not.

Rotary engines: Present

The days of having rotary engines in your car precisely ended more than a decade back. This extremely liked engine from the past lost its potential with the arrival of better and more efficient engines. Because of several drawbacks and its requirement of strict maintenance, production companies gave up on the rotary engine’s potential a long time back.

But recently, the Japanese company Mazda has revealed that it still produces rotary engine mechanisms. Mazda is the company the market stays on the lookout for when it comes to rotary engine production. They are known to be experimenting with the engine since the 1960s. The company stopped producing rotary engine-run vehicles back in 2012. But they continue to manufacture some of the main components of the rotary engine.

Mazda Vehicles

Mazda’s RX-8 was primarily made with two rotary engines. The vehicle was extremely hyped when it came out. But with time, it was found that the vehicle was too slow and required a great deal of maintenance to be run smoothly. Although, this is not the only rotary engine vehicle Mazda released. Their vehicles RX-7 and a newly designed version of Mazda-2 comprised rotary engines as well.

Again recently, the company has revealed its intention of building a complete new rotary engine mechanism. They plan to use this new mechanism alongside electric motors for their hybrid electric vehicles. Currently, the only vehicles by Mazda that are running with rotary engines are race cars in their American Pro Mazda Junior series.

As Mazda is determined to bring back rotary engine vehicles, the market is on a great lookout for the outcome. If Mazda’s initiations receive a welcome in the business, other production companies may also consider rotary engines for their vehicles.

Are Rotary Engines Reliable: Vehicles That Used Rotary Engine

Like we discussed earlier, rotary engine vehicles are no longer in the run. But in the early 1960s and 70s, rotary engines were used by several production companies. Some of these vehicles and their properties were like the following.

Are Rotary Engines Reliable: 1970 Mazda RX-500

Even though this car seemed great with its looks, Mazda never ended up releasing it in the market. The model had a great power generating ability with its rotary engine.

Are Rotary Engines Reliable: 1970 Mercedes Benz

With all the hype in the market during the 70s, Mercedes also came up with their product of rotary engine. The car was an excellent output, but eventually, Mercedes realized the shortcomings of rotary machinery. That is why they stopped production of the vehicle using rotary engines. Instead, they swapped those with piston ones.

Are Rotary Engines Reliable: 1973 Chevrolet Corvette

This model produced by General Motors could have been a great competitor to the RX-7 model by Mazda. What ruined this model was its excessive requirement of fuel.

Are Rotary Engines Reliable: 1975 Mazda Road Pacer

In this concept, Mazda took an attempt to minimize air pollution with rotary engines. But similar to a previous case, the vehicle resulted in being slower in speed. It ended up being a loss purchase for the models that were sold.

As we can understand from the three mentioned examples, almost every famous motor production company took their chances with rotary engines. But eventually, all of them came to a halt. The rotary engines would perform excellently in their initial time, but end up being the purchase of loss.

Thus, the reputation of rotary engines slowly came to an end. And like aforementioned, there hasn’t been any production of motors comprising the engine in the entire last decade.

Are Rotary Engines Reliable: Research And Development

Mazda is relentlessly working and researching its best to deliver some great outcomes of the rotary engine. In earlier times, almost every manufacturing company researched and planned to develop the concept of rotary engines. But as the piston engines became a go-to approach for the consumers, eventually every company gave up in their tries.

Mazda is still running its research on rotary engines. Their production of concept cars like the RX-Vision shows their continued research in the field.

Final Verdict: Are Rotary Engines Reliable?

With all that brief discussion on rotary engines, their advantages, and disadvantages; it is time to answer the main question now. Are rotary engines reliable?

Our final answer is no. The first reason is all the drawbacks of the engine. Yes, the engine has some notable pros. But those do not catch the eye when we talk about the cons that come along. Even though the engine has a smoother functionality and simple mechanism, the emission and maintenance issues are some major issues.

Rotary engines sure had their own time to shine back in the days. But in today’s time where motor production companies are upgrading their quality more and more regularly, rotary engines do not stand a chance. It is 2021, and now we have cars that run on batteries instead of engines. And the fact to note here is such development in vehicles is happening rapidly throughout some of the most popular production companies around the globe.

If Mazda can successfully come up with the hybrid model they are eyeing, rotary engines might still hold a valuable existence in the market. Other than that, rotary engines are not making their comeback in the market anytime soon. The reliability of an engine depends on its overall performance of efficient delivery. In the case of the rotary engines, we cannot count on this reliability with a hundred percent assurance.

Conclusion

Having said all that, we can answer the question of whether are rotary engines reliable in today’s market or not. We can also understand very clearly why the answer is a no.

If production companies like Mazda continue their rapid research on rotary engines, then maybe we will get to see a good outcome of this engine in the future. But until we reach that point, the rotary engines can only be appreciated for their excellent services from the old days.