To many drivers, the internal workings of a car are a mystery. The statement only gets truer as more technical elements are brought into the discussion. After all, we do not have to know every part of the engine to drive a vehicle. However, those technical bits are just as important as their better-known companions. Hence, the importance of understanding bad lifter symptoms.

When one starts to fail, you are bound to notice. One of those key technical components in the vehicle’s hydraulic lifter. Regardless of whether you suspect a faulty lifter due to bad lifter symptoms or simply want to know what to keep an eye out for, we will break it down here. In addition, we will also talk about the function of a hydraulic lifter, where you can find it in your vehicle, and the replacement cost of the lifter.

- Types of Lifters

- Hydraulic Lifters

- Bad Lifter

- Symptoms

- Faulty Hydraulic Lifter

- Cost

- Quiet Noisy Lifters

- Clean Dirty Lifters

What Are Lifters?

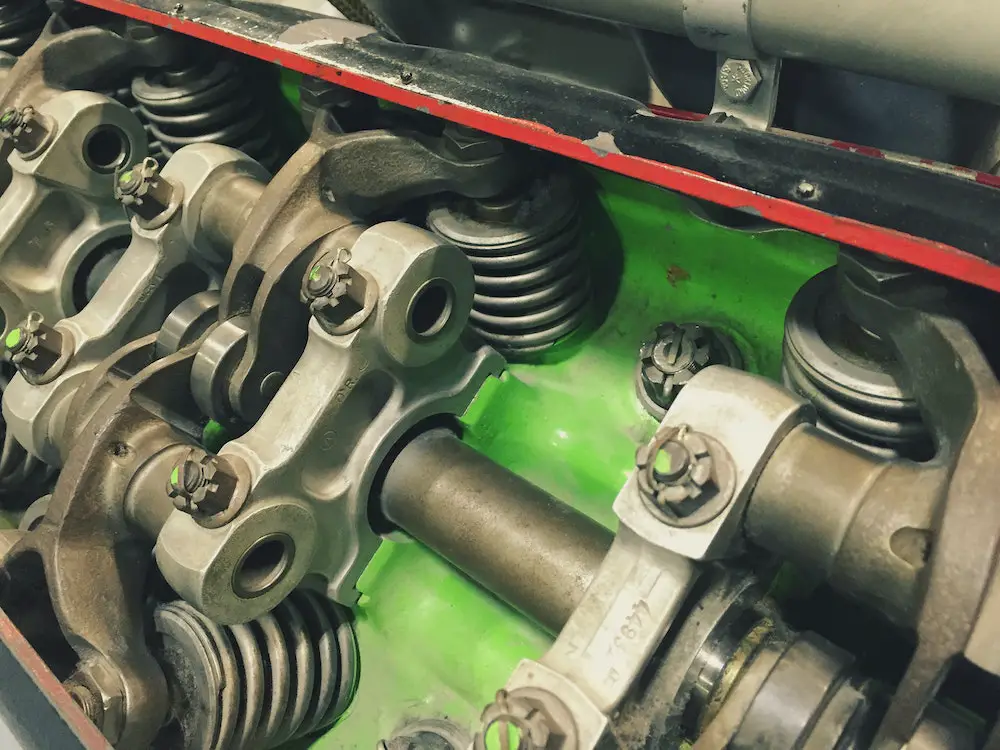

Lifters are an essential component of the engine head that is in charge of controlling the opening and closing of the exhaust and intake valve. Complex mechanisms by nature, valve trains have multiple moving parts. To function properly, all parts need to be in perfect sync.

The rocker arms, valve springs, hydraulic lifters, exhaust and intake valves, valve seats, and valve guides are all part of the modern-day dual overhead camshaft or overhead camshaft valve train design.

All the parts of a valve train are equally important. Some parts are more prone to damage than others yet still bear equal importance in keeping the engine functioning smoothly. One of those parts is the lifter. The hydraulic lifters are tasked with maintaining a constant clearance between the camshaft lobes and the valves, making sure the timing on the opening and closing of valves is perfect.

When automobile manufacturers started the use of hydraulic valve lifters, they eliminated the requirement for constant valve clearance adjustment. Not only did this save a lot of time for the car owners, but it also reduced costs.

Hydraulic lifters contain engine oil. The lifter is filled with engine oil when the valve is in a closed state. After that, the camshaft lobe presses the lifter piston and lifter. An internal valve shuts off the oil inlet. Once filled with oil, the lifter cannot be compressed anymore, making it like a solid piece.

When the camshaft keeps turning, the load on the lifter is decreased. As the internal mechanism of the lifter returns to its neutral state, it is once again ready to be refilled with oil.

A series of lifters help operate the vehicle’s valves inside. There are a few lifter designs mainstream in different engines. Lifters also differ in terms of their function.

Different Types Of Lifter

To understand all about lifters and how they could turn out to be ineffective, you have to know the different types of lifters.

Lifters According To Engines

The first category that we’re going to cover now is lifters according to engines. These are further categorized into several types.

Lifters In OHV Engines

Traditionally, “lifter” was a term associated with the description of components in the OHV or overhead valve engine that follows the camshaft’s contours. As the camshaft rotates, the lifters work on a series of pushrods. In turn, it operates the rocker arms to close and open the valves of the engine. The lifters also regulate the clearance of the engine’s valve train lash.

Lifters can be hydraulic or solid – something we will get into later. With solid lifters, the valve train lash has to be adjusted from time to time. In contrast, hydraulic lifters depend on pressurized engine oil to adjust the last automatically, canceling the need for manual periodic adjustment.

Moreover, there are roller lifters and flat lifters (tappets). Flat lifters, generally found in vintage vehicles, feature a relatively flat face. Meanwhile, wheel-like roller lifters characterize roller lifters. Since the ‘90s, almost all OHV engines come with roller lifters.

Lash Adjusters In OHC Engines

Today, hydraulic lash adjusters located in the OHC (overhead camshaft) engines can also be called lifters. The lash adjusters fix the clearance within the valve train components. Based on the design of the engine, each lash adjustment might be located between a camshaft follower and the cylinder head, built inside the rocker arm, or inside a bucket over the valve.

Lifters According To Functionality

Lifters are also categorized according to their functionality. Let’s see what they are.

Hydraulic Lifters

Hydraulic lifters were invented in the ‘30s to decrease the noise from old mechanical lifters. In today’s time, they are the most common kind of lifter available on the market. However, due to their higher prices, they were not a regular addition to most vehicles until the 1950s.

This is how they work:

- Through a hole in the body of the lifter, pressurized oil enters and flows inside a narrow channel. Although the oil enters the internal lifter cylinder, it flows freely on the other side.

- The channel is closed when the camshaft compresses the lifter piston. As a result, the valve open is locked temporarily, even under high pressure to facilitate the escape of gas from the cylinder.

- When the camshaft passes its apex, the oil can once again flow freely as the lifter piston rises. In turn, it makes the valve snap shut, maintaining the proper engine air pressure.

- The floating piston design tries to decrease valve lash. A larger volume of the lash is forgiving but can create a knocking and rattling noise. The lesser the lash, the smoother and quieter the ride.

A good pair of hydraulic lifters will decrease valve lash to 0.006”. The problem, in this case, is that the lifter has to work to precise tolerances so it can accomplish its job. If the RPMs are excessively high inside the engine, it does not give the oil enough time to re-pressurize the valve entirely, resulting in poor performance and reduced airflow.

On the other hand, a hydraulic lifter that gets over-pressurized cannot close the valves completely. As a result, leakage happens which can damage the valve to the point of no return. After a certain state, it will prevent ignition.

Mechanical Lifters

Through the ‘50s to ‘80s, hydraulic lifters were all the rage. They were found in about every vehicle on the road. That being said, some newer vehicles do come with mechanical lifters.

Although louder, mechanical lifters have some important advantages over their hydraulic versions. First of all, they are inexpensive and low-maintenance, making them the perfect fit for economy cars. Secondly, they work just as fine for performance cars since they can maintain working conditions at higher RPMs.

There are mainly two types of mechanical lifters: roller lifters and solid lifters. A solid lifter is a solid metal cylinder; exactly what it sounds like. As the camshaft turns, it either compresses the cylinder or lets it rise. Roller lifters come in a similar structure but are designed to reduce the sound from solid lifters. Rather than a flat back, they feature rollers on the back which allow the camshaft to turn over the top smoothly.

This reduces noise and elevates performance significantly, especially at higher RPMs. Conversely, the rollers are more expensive to maintain than ordinary solid lifters, leading to greater mechanical bills.

Where Are Hydraulic Lifters Located?

When the bad lifter symptoms start showing up, you have to repair or replace the lifters promptly. But for that, you must know where the lifters are located. Hydraulic lifters can be found right between the engine’s valves and camshaft in most car models. However, pushrods and rocker arms can also be found in some car models.

As the location of the camshaft can vary, this makes it slightly more difficult to pinpoint whether the hydraulic lifters will be at the bottom or top of the engine. Here’s an easy way to remember this: if your vehicle features hydraulic lifters and you find your camshaft, that is where they will be.

Even if the vehicle does not have hydraulic lifters, a mechanical lifter of some kind will be there as a replacement. You will never find a vehicle with a camshaft pushing directly against the valves or pushrods.

Bad Lifter Symptoms: What Does A Bad Lifter Sound Like?

Being aware of what a bad lifter sounds like can save you plenty of money. If you can recognize and diagnose the problem early, you can also solve them early. Instead of the sudden knocking, a faulty hydraulic lifter will keep making an incessant tapping noise. The tapping happens in rapid succession and will only get worse with time.

Based on the exact location of the lifters, the sound can happen regardless of whether your vehicle has a cold or hot engine. For more severe bad lifter symptoms, you might hear a loud banging or knocking noise.

The lifter problem may occur due to:

- Lifter spacing problems

- A protruding check valve

- Dirt in the system or lifter wear

- Lack of grease or contaminated engine oil

- Irregular servicing

- High vehicle mileage

- Faulty/clogged engine oil filter

- Using the wrong engine oil

Bad Lifter Symptoms

Apart from the noisy valve lifters, bad lifter symptoms include:

Bad Lifter Symptoms: Excessive Engine Noise

When one of the hydraulic lifters of your vehicle is broken or stuck, the sound is going to be noticeable. You will hear the clanging sound of metal as they collide against each other. Furthermore, the lifter’s internals will be hammering against each other which will result in another kind of noise.

As the vehicle speeds up to higher RPMs, the sounds will worsen and become more frequent. The lifter will try to actuate faster but will fail, causing the noises.

Bad Lifter Symptoms: Engine Misfires

In a few car models, the hydraulic lifters are attached to the pushrods, which are connected to the rocker arms. These control the exhaust and intake valves. So, if the hydraulic lifter’s functioning is not normal, then the exhaust and intake valves will not be opening and closing as they were meant to be.

The engine will fail to create the required combustion, leading to a misfire. A misfiring engine sounds much different from a regular one, and there is a significant drop in performance. If your vehicle’s engine is misfiring, it is crucial to get that checked by a certified professional as soon as you can.

Bad Lifter Symptoms: Dead Cylinders And Broken Pushrods

We already mentioned how the pushrods are connected to the intake and exhaust valve and the camshaft in an OHV engine. If the hydraulic lifter is bad, these can break down. The only reason there is a lift cylinder in the engine is to push the pushrod in the exact same way time and time again. Thanks to a broken hydraulic cylinder, the pushrods break or bend with time.

If this happens, the intake or exhaust valve does not work optimally. A cylinder that has stopped working is called a “dead cylinder,” and it leads to a significant fall in performance. In addition, the engine will not sound right anymore.

A dead cylinder has to be checked out immediately. It is much more than simply restoring the horsepower of the engine. If you choose to leave the cylinder broken, it is only a matter of time before it starts causing major (and expensive) damages to other parts of the engine.

Bad Lifter Symptoms: Check Engine Light

An engine is filled with sensors from the start to the end. They track everything, from the chemical composition of the exhaust to the air intake of it. A vehicle is a collaboration of many fine-tuned machines. All the inputs have to be functioning optimally for the vehicle to perform.

So, it is only logical that the sensors will know something is up with the vehicle when the symptoms are erratic. There are many warning signs that may turn on if there is a faulty hydraulic lift cylinder. One thing is for sure – the check engine light will go on.

What To Do If There Is A Faulty Hydraulic Lifter?

When you are sure that the bad lifter symptoms were not an illusion and the lifter is indeed, damaged, replace it immediately to avoid further damaging the engine. In most cases, the lifter will just have to be replaced. Depending on the make and model of your car, you may be able to get away with changing one bad hydraulic lifter.

Having said that, many mechanics recommend replacing all the lifters when you replace one because it is mostly a solid indication that the others will follow suit and fail soon. Some older vehicles do not have new lifters in production anymore so consider refurbished lifters if your car is one of those. Refurbished hydraulic lifters are cheaper and work quite fine for older vehicles that might not have many years of service ahead of them.

How Much Does It Cost To Solve Bad Lifter Symptoms?

The cost of engine lifter replacement is not cut and dries due to many reasons. The cost figure is fairly straightforward if you want to just replace one, but we do suggest replacing all of them – as you would do with spark plugs.

The price of the lifter itself falls anywhere between $5 to $35. This amount can change drastically if you choose to replace all the lifters in the engine. As a rule of thumb, there are 2 lifters in each valve, meaning you might have to replace 2 to 32 lifters or somewhere in the middle. Remember to add the cost of bolts, gaskets, and other parts which can hike up the final bill.

A decent alternative is purchasing a complete lifter replacement kit. An aftermarket kit goes for less than individual OEM parts to be acquired from a dealership. However, quality is a top concern.

Labor costs will not be cheap either. Once more, based on the engine, it can be a 3-hour job at the very least or a 10-hour job at the very most. Labor rates vary all across the world but assuming the rate is $100 per hour, you are looking at a final bill of something between $300 to $1,000 just for labor.

When discussing the total replacement costs, coming up with an average cost is difficult. But as an example, 16 lifters come in a common V8 engine so expect to pay about $1,000 to $2,000 based on the quality of the parts as well as whether the repair is being done at the dealership or by an independent mechanic.

You can save quite a bit of money by going for refurbished lifters rather than new ones but that has no effect on the labor cost.

How Long Can You Drive With Bad Lifter Symptoms?

With collapsed or bad lifters, you should not drive more than 100 miles. Keep in mind that these miles should be spent driving to the repair shop. When a vehicle operates for too long on bad lifters, the inners of the lifters can deteriorate to the point where they cause damage to the camshaft. The roller on the lifter scratches the camshaft and messes with the overall functioning of the vehicle.

Ultimately, the camshaft damages will have to be fixed after 10,000 to 15,000 miles.

How To Quiet Noisy Lifters

Use these tips and tricks to prevent noisy lifters. Also, check out this video.

- Regular oil changes: Even aside from the bad lifter symptoms, regular oil changes can help keep a vehicle running smoothly. Changing oil at the right time prevents low levels of oil or dirty oil from damaging the lifter.

- Try an oil additive: Good oil additives like Marvel Mystery Oil or Liqui Moly can improve the condition of the engine oil while cleaning the lifters. Additives like these can also clean valves, rocker arms, and other engine bits. This is the best thing to do as it is a cheap fix.

- Modify the Lifter Spacing: Sometimes, the lifter noise remains even though there is technically nothing wrong with it. Have a mechanic adjust the spacing between the components of the engine and the lifter. Refer to your owner’s manual for specific lifter spacing.

How To Clean Dirty Or Clogged Lifters

If the lifters are dirty or clogged, a constant ticking noise will be heard which is very different from the regular engine noise. Dirty or clogged lifters can easily be cleaned and will save you some coins. But, cleaning will not be enough if the lifters are collapsed or stuck. This is when replacement is a must. This is how you clean clogged or dirty lifters:

- With the vehicle parked outside or in the garage, start it and leave the door open as the engine will be running in the next 10 minutes.

- Open the hood and find the engine oil cap. Remove it.

- Pour in the engine treatment product and allow the car to run for around 10 minutes.

- Hop inside the vehicle and hit the gas pedal, making sure to maintain 2000 RPMs for 2 minutes.

- If the ticking noise persists, keep the gas pedal pressed for about 2 more minutes.

- At this point, the lifters should be clean and the ticking sound should be gone entirely.

Facts: Cost and Symptoms of Faulty Engine Lifters

- Engine lifters are steel cylinders that transfer motion from the camshaft to the engine valves, and they require engine oil to function correctly.

- There are three types of engine lifters: hydraulic valve lifters, mechanical lifters, and roller lifters.

- The cost to replace faulty engine lifters ranges from $900 to $2,300, depending on the number of cylinders and the car’s make, model, and year. A mechanic would charge $1,000 to $2,500 for the replacement job.

- Symptoms of faulty engine lifters include knocking noises from the engine, vibrations while driving, difficulty in accelerating, decreased gas mileage, engine misfires and rough running, and engine warning lights.

- Driving with faulty engine lifters is not recommended, as it can cause further damage to the car and be more expensive to repair than simply replacing the lifters.

- To fix noisy engine lifters, one should change the oil regularly, use the right engine oil, and use an oil additive to clean the lifters. If the noise persists, one can adjust the spacing between the lifter and other engine components.

Bad Lifter Symptoms Conclusion

In event of a tapping sound is emitted from clogged lifters, regardless of whether the engine has manual or hydraulic lifters, make sure to clean first before considering a replacement. Replacement can cost thousands of dollars!

The aforementioned tips will help you identify, fix, and/or quiet bad lifter symptoms. If you notice any of these signs in your car, do not ignore them. Take them to a licensed mechanic quickly and save your vehicle.

Bad Lifter Symptoms FAQ

Here are some popular FAQs:

How Do You Fix A Bad Lifter?

A bad lifter has to be replaced. The procedure is quite labor-intensive, as it includes some degree of engine disassembly.

Does A Bad Lifter Cause Loss of Power?

A bad lifter can result in a loss of power and make your vehicle stutter.

What Happens If You Drive With A Bad Lifter?

Expensive repairs are just the start. A bad lifter damages the catalytic converter, camshaft, and also causes internal engine failure. So, if your vehicle has one or multiple lifter failures, the problem should be addressed right away.