- What is a Catalytic Converter Made Of

- How Does a Catalytic Converter Work

- Benefits of Using a Catalytic Converter

- Common Problems with Catalytic Converters

- Diagnose and Repair a Catalytic Converter

- Different Types of Materials Used

- Impact of Temperature on the Performance

- Chemistry Behind the Catalytic Converter

- Automotive Emission Control Systems

- Different Brands of Cataylic Converters

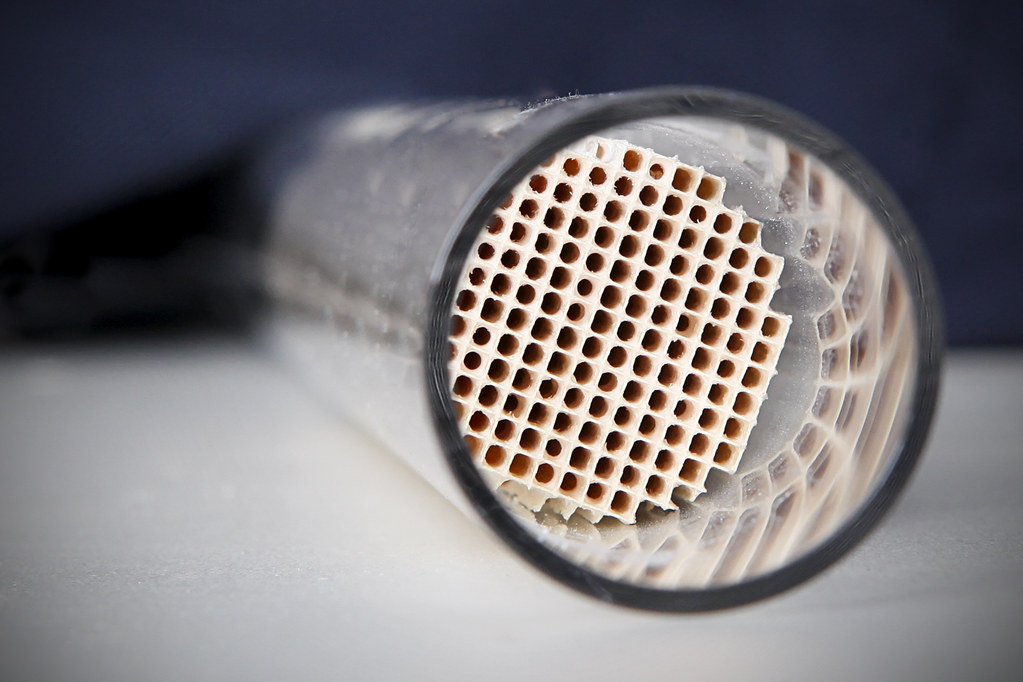

What is a Catalytic Converter Made Of?

A catalytic converter is a device that is used to reduce the number of harmful pollutants emitted from an internal combustion engine. It is typically made up of three main components: a ceramic honeycomb substrate, a wash coat, and precious metal catalysts.

The ceramic honeycomb substrate acts as the support structure for the other two components. It is usually made from cordierite or aluminum titanate and has hundreds of tiny channels running through it. These channels allow exhaust gases to pass through while also providing enough surface area for the other two components to be effective.

The wash coat component consists of an alumina-based material that has been treated with various chemicals such as silicon dioxide, titanium dioxide, and zirconium oxide. This coating helps to increase the surface area available for chemical reactions and also helps protect against corrosion caused by high temperatures in the exhaust system.

Finally, precious metal catalysts are added on top of this wash coat layer to facilitate chemical reactions between pollutants in exhaust gases and oxygen molecules from outside air sources. Commonly used metals include platinum, palladium, rhodium, and sometimes even gold or silver depending on application requirements.

How Does a Catalytic Converter Work?

A catalytic converter is an important component of a vehicle’s exhaust system. It is designed to reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances.

The catalytic converter works by using a combination of chemical reactions and physical processes to convert toxic gases, such as carbon monoxide and hydrocarbons, into harmless compounds like carbon dioxide and water vapor.

The catalytic converter consists of two main components: a catalyst substrate and a catalyst coating. The substrate is typically made from ceramic or metal honeycomb structures that provide a large surface area for the reaction to take place on.

The catalyst coating is usually composed of precious metals such as platinum, palladium, or rhodium which act as the active sites for the chemical reactions that occur within the converter. To learn more, do check out our explainers on which catalytic converters have the most rhodium, as well as how much platinum is in a catalytic converter.

When exhaust gases enter the catalytic converter they are exposed to high temperatures which cause them to react with oxygen in presence of these precious metals. This reaction causes pollutants like carbon monoxide and hydrocarbons to be converted into less harmful substances like carbon dioxide and water vapor before being released out through the tailpipe.

The efficiency of this process depends on several factors including temperature, air-fuel ratio, engine speed, load conditions, etc., so it’s important that all these parameters are kept within their optimal range for maximum efficiency from your vehicle’s catalytic converter system.

The Benefits of Using a Catalytic Converter

A catalytic converter is an important component of a vehicle’s exhaust system. It is designed to reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances. The use of catalytic converters has become increasingly important in recent years due to increasing environmental concerns and regulations.

- The primary benefit of using a catalytic converter is that it helps reduce air pollution. Catalytic converters work by converting toxic gases such as carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide, water vapor, and nitrogen gas. This process helps reduce the amount of these pollutants released into the atmosphere, which can have a positive impact on air quality and public health.

- In addition to reducing air pollution, using a catalytic converter can also help improve fuel efficiency. By reducing emissions from vehicles, they can run more efficiently which can lead to improved fuel economy over time. This can result in significant savings for drivers who use their vehicles regularly or for long distances.

- Finally, using a catalytic converter may also help extend the life of your vehicle’s engine by reducing wear on its components caused by excessive emissions from combustion processes within the engine itself. By helping keep these components clean and free from buildup over time, they can function more effectively which can lead to improved performance and longevity for your vehicle’s engine overall.

Overall, there are many benefits associated with using a catalytic converter in your vehicle’s exhaust system including reduced air pollution levels; improved fuel efficiency; and extended engine life due to reduced wear on its components caused by excessive emissions from combustion processes within the engine itself.

Common Problems with Catalytic Converters

The catalytic converter is an important part of a vehicle’s exhaust system, as it helps to reduce the number of harmful emissions released into the atmosphere. Unfortunately, these components can be prone to problems and failure. Common issues with catalytic converters include clogging, overheating, and damage due to fuel contamination.

- Clogging is one of the most common problems associated with catalytic converters. This occurs when particles such as soot or ash build up inside the converter and block its flow. This can cause a decrease in engine performance and an increase in emissions levels. To prevent this from happening, it is important to regularly maintain your vehicle’s exhaust system by replacing air filters and spark plugs regularly. So, be on the lookout for the symptoms of a clogged catalytic converter, as well as whether can a bad catalytic converter cause a misfire.

- Overheating is another issue that can affect catalytic converters. When the component gets too hot due to excessive use or lack of maintenance, it can cause damage to its internal components which will lead to decreased performance or even complete failure of the unit. To avoid this problem, make sure you are not overworking your engine by driving at high speeds for extended periods of time or carrying heavy loads in your vehicle for long distances without taking breaks in between trips. Additionally, ensure that you are regularly checking your oil levels and replacing any worn-out parts as needed so that your engine does not become too hot while running. You can confirm this with a catalytic converter temperature test.

- Finally, fuel contamination can also be a problem for catalytic converters if there are impurities present in the gasoline being used by your vehicle’s engine such as dirt or water droplets which could potentially damage its internal components leading to decreased performance or complete failure of the unit altogether. To prevent this from happening make sure you only use clean gasoline when filling up your tank and check for any signs of contamination before doing so if possible (elevated levels of sediment). Additionally, have any necessary repairs done immediately if you notice any changes in how well your car runs after refueling it with contaminated gasoline so that further damage does not occur over time due to prolonged exposure.

How to Diagnose and Repair a Faulty Catalytic Converter

The catalytic converter is an important component of a vehicle’s exhaust system. It helps to reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances.

Unfortunately, it can become faulty over time due to a variety of reasons, such as age or damage from road debris. If you suspect that your catalytic converter is not functioning properly, it is important to diagnose and repair the issue as soon as possible to avoid further damage and costly repairs.

To diagnose a faulty catalytic converter, start by checking for any visible signs of damage or corrosion on the exterior of the part. If there are no obvious signs of damage, then you should check for any error codes that may be present in your vehicle’s computer system.

These codes can indicate issues with the catalytic converter and provide more information about what needs to be done to repair it. Once you have identified that there is an issue with your catalytic converter, you will need to replace it with a new one to restore proper function.

Before replacing the part, make sure that all other components related to its operation are also inspected and replaced if necessary (e.g., oxygen sensors). Once everything has been checked and replaced if needed, install the new catalytic converter according to manufacturer instructions and reconnect all related components before starting up your engine again for testing purposes.

If done correctly, these steps should help diagnose and repair any issues with your vehicle’s faulty catalytic converter so that it can continue functioning properly once again without releasing excessive amounts of pollutants into our environment.

The Different Types of Materials Used in Making a Catalytic Converter

A catalytic converter is an important component of a vehicle’s exhaust system, as it helps to reduce the number of harmful pollutants released into the atmosphere. It works by converting toxic gases such as carbon monoxide and hydrocarbons into less harmful substances like carbon dioxide and water vapor.

To achieve this, catalytic converters are made from a variety of materials that are designed to withstand high temperatures and chemical reactions.

- The most common material used in making a catalytic converter is ceramic, which is composed of aluminum oxide or other metal oxides. This material has excellent heat resistance properties and can withstand temperatures up to 1,400 degrees Celsius (2,552 degrees Fahrenheit). Ceramic also has good thermal shock resistance which means they can handle sudden temperature changes without cracking or breaking.

- Another type of material used in making a catalytic converter is stainless steel mesh. This mesh acts as a support structure for the ceramic substrate and helps to keep it in place during operation. The mesh also provides additional strength so that the substrate does not break under extreme conditions such as high engine speeds or vibrations caused by road bumps.

- In addition to these two materials, some catalytic converters also contain precious metals such as platinum, palladium, or rhodium which act as catalyst agents for chemical reactions within the device. These metals help speed up the process of converting toxic gases into less harmful substances before they are released into the atmosphere.

- Finally, some manufacturers may use other materials such as fiberglass insulation or graphite foam in their designs depending on their specific needs and requirements for performance and durability.

Overall, there are several different types of materials used in making a catalytic converter including ceramic substrates with stainless steel mesh supports along with precious metal catalysts agents like platinum or palladium for improved efficiency levels when dealing with toxic emissions from vehicle engines.

The Impact of Temperature on the Performance of a Catalytic Converter

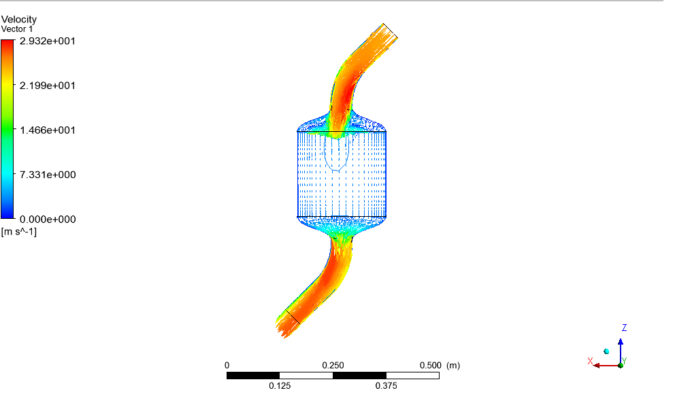

“File:Catalytic-Converter-Simulation-Velocity-Vectors-and-Contours.jpg” by Atif Masood (FetchCFD) is licensed under CC BY-SA 4.0

Catalytic converters are an essential component of modern automobiles, as they help reduce the number of harmful emissions released into the atmosphere. However, their performance is greatly affected by temperature. This article will discuss how temperature impacts the performance of a catalytic converter and what measures can be taken to ensure optimal operation.

The efficiency of a catalytic converter is largely dependent on its operating temperature. When temperatures are too low, the chemical reactions that take place within the converter are not able to occur at an optimal rate, resulting in reduced efficiency and increased emissions.

Conversely, when temperatures become too high, it can cause damage to both the catalyst material and other components within the converter itself. For a catalytic converter to operate at peak efficiency, it must remain within a certain range of temperatures; typically between 200-600°C (392-1112°F).

To achieve this range of temperatures under normal driving conditions requires careful management from both engine design and exhaust system design perspectives. Engine design should focus on optimizing combustion parameters such as air/fuel ratio and spark timing to maximize heat generation while minimizing exhaust gas flow restrictions that could impede heat transfer from engine cylinders into exhaust gases passing through the catalytic converter.

Exhaust system design should focus on providing adequate insulation around hot components such as manifolds or turbochargers while also ensuring sufficient airflow through all parts of the system so that heat generated by these components can be dissipated quickly enough before reaching downstream components like catalytic converters or mufflers which may not be able to withstand high levels of sustained heat exposure without suffering damage over time.

In addition to proper engine and exhaust system design considerations, there are also several aftermarket products available that can help maintain optimal operating temperatures for your vehicle’s catalytic converters even under extreme driving conditions such as off-roading or racing applications where higher levels of power output may generate more heat than what would normally be encountered during everyday driving scenarios.

These products include ceramic coatings which provide additional insulation against excessive heat buildup along with thermal wraps designed specifically for use around hot exhaust components like headers or turbochargers to keep them cooler than they would otherwise run without any additional protection being applied beforehand.

In conclusion, temperature plays an important role in determining how efficiently a catalytic converter operates; if it gets too hot or too cold then its performance will suffer accordingly due to either reduced reaction rates or physical damage caused by excessive thermal stress respectively.

Therefore it is important for automotive engineers and enthusiasts alike to understand how temperature affects their vehicles’ emission control systems so that they can take appropriate steps toward ensuring optimal operation regardless of driving conditions encountered throughout their vehicles’ lifetimes.

Understanding the Chemistry Behind the Functioning of a Catalytic Converter

A catalytic converter is an important component of a vehicle’s exhaust system, responsible for reducing the number of harmful pollutants released into the atmosphere. It works by converting toxic gases such as carbon monoxide and hydrocarbons into less harmful substances like carbon dioxide and water vapor. To understand how this process works, it is necessary to look at the chemistry behind it.

The catalytic converter contains a ceramic honeycomb structure coated with precious metals such as platinum, palladium, and rhodium. These metals act as catalysts that speed up chemical reactions without being consumed in the process. When exhaust gases pass through the converter, they come into contact with these metal surfaces which causes them to break down into simpler molecules.

For example, when carbon monoxide (CO) passes through the catalyst it reacts with oxygen (O2) to form carbon dioxide (CO2). This reaction is known as oxidation and requires energy to occur:

CO + O2 → CO2 + Energy

Similarly, hydrocarbons are broken down by a process called combustion:

CH4 + 2O2 → CO2 + 2H20 + Energy

In both cases, energy is released in the form of heat which helps reduce emissions from vehicles. The end result is cleaner air for everyone.

Exploring the Latest Technologies in Automotive Emission Control Systems

The automotive industry is constantly evolving, and the latest technologies in emission control systems are no exception. Featuring catalytic converters, these systems are designed to reduce harmful emissions from vehicles and help protect the environment. In this article, we will explore the latest advancements in automotive emission control systems featuring catalytic converters.

- Catalytic converters are devices that use a chemical reaction to reduce pollutants from vehicle exhausts. They work by converting toxic gases such as carbon monoxide and hydrocarbons into less harmful substances like nitrogen and water vapor. The most common type of catalytic converter is a three-way catalyst, which uses platinum, palladium, and rhodium to break down pollutants into harmless compounds.

- The latest advancements in automotive emission control systems featuring catalytic converters include improved efficiency through higher temperatures and increased durability due to better materials used in their construction. These improvements have resulted in greater fuel economy for vehicles equipped with these systems as well as reduced emissions of hazardous air pollutants (HAPs). Additionally, some newer models feature active regeneration technology which helps keep the system clean by burning off accumulated soot particles before they can build up on the filter media inside the converter itself.

- In addition to improved efficiency and durability, modern catalytic converters also offer enhanced safety features such as thermal protection against overheating or overloading of components within the system itself. This helps prevent potential damage caused by excessive heat or pressure buildup within the converter housing while also providing additional protection against fire hazards associated with hot exhaust gases passing through it at high speeds during the operation of a vehicle’s engine.

- Finally, many new models now feature advanced diagnostic capabilities that allow technicians to quickly identify any issues with an individual component or system without having to disassemble it for inspection purposes first – saving time and money when servicing vehicles equipped with these types of emission control systems featuring catalytic converters.

Overall, the latest technologies in automotive emission control systems featuring catalytic converters provide numerous benefits including improved efficiency, increased durability, enhanced safety features, and advanced diagnostic capabilities. By utilizing these advances, vehicles can be made more efficient while reducing their environmental impact at the same time.

Comparing Different Brands and Models of Aftermarket Catalytic Converters

When it comes to aftermarket catalytic converters, there are a variety of brands and models available on the market. It is important to understand the differences between them to make an informed decision when selecting one for your vehicle.

- One of the most popular brands is the Magnaflow catalytic converter, which offers a wide range of catalytic converters for both gasoline and diesel engines. Their products are designed with stainless steel construction and feature high-flow designs that allow for maximum exhaust flow while still providing excellent emissions control. They also offer direct-fit models that are designed specifically for certain makes and models of vehicles, making installation easier than ever before. For a more in-depth look, check out our explainer on the high-flow catalytic converter models from Magnaflow.

- Another popular brand is Flowmaster, which specializes in performance exhaust systems. Their catalytic converters feature stainless steel construction as well as high-flow designs that provide superior emissions control without sacrificing power or performance. They also offer direct-fit models that make installation easy and hassle-free.

- Finally, Borla offers a line of aftermarket catalytic converters designed with stainless steel construction and high-flow designs that provide superior emissions control while still allowing maximum exhaust flow through the system. They also offer direct-fit models specifically designed for certain makes and models of vehicles, making installation quick and easy.

No matter which brand or model you choose, it is important to ensure you select one that meets your specific needs in terms of performance, emissions control, fitment requirements, cost-effectiveness, etc., so be sure to do your research before making a purchase decision.