Launched as a replacement for the Gen IV Vortec, now so-called EcoTec3, GMC’s all-new 6.2-liter V8 pushrod engine was as widespread as General Motors itself. Common designations and variants like the L86/L87 were used mainly in trucks, like the Silverado, Sierra, Tahoe, Yukon, Escalade, and Suburban. Nonetheless, there are GMC 6.2 engine problems to be wary of.

Then, there was the LT1, used in the C7 Corvette and the Camaro, as well as the LT2, used in the C8 Corvette. Not to mention, the LT4, which was used for the Corvette Z06, Camaro ZL1, and other high-performance vehicles in GM’s stable, as well as the LT5, used in the Corvette ZR1; one of the most powerful engines ever made. For now, though, we’ll focus on the L86 and L87.

For the most part, GMC’s L86 and L87 V8s are highly reliable and durable powertrains, for long-term ownership and where minimal maintenance is needed. There are never any questions about the longevity of the engine block, given that it’s a proven design. However, some of the newer tech that it’s incorporated is what causes these GMC 6.2 engine problems.

Top 5 Most Common GMC 6.2 Engine Problems

Among the design changes and engineering updates seen in GMC’s L86/L87 6.2 V8 is the use of an all-aluminum block. It’s a super lightweight design, and to ensure it could take the punishment from all that compression, it still uses iron cylinder sleeves. Plus, the GMC 6.2’s cylinders are positioned at a 90-degree angle, just like classic pushrod designs.

Just like all other Gen 5 blocks, the GMC 6.2 L86/L87 features a 103.25mm bore and a 92mm stroke. Since it uses a pushrod design, these V8 engines don’t use an overhead camshaft, unlike other modern V8s. Still, pushrod engines are well-regarded and proven for their superior long-term reliability, and it’s also cheaper to run, and cheaper to maintain.

Aside from these, there are two new additions to these engines that feature prominently when looking at GMC 6.2 engine problems… Direct injection, as well as GM’s AFM (active fuel management). The latter is otherwise known as ‘displacement on demand’, whereby some of the cylinders can turn off, allowing the engine to save fuel while driving.

With that in mind, here are some of the most common GMC 6.2 engine problems:

1. Lifters Collapsing And Causing Bent Pushrods

General Motors’ AFM (Active Fuel Management) allows GMC’s 6.2 V8 to basically just run on 4 mere cylinders if they’re not being used. This is meant to help improve fuel economy. The bad news here is that the AFM system actually (inadvertently) causes damage to the engine’s pushrods. This is mainly due to the complex lifters that GMC uses for the AFM.

These complex lifters are prone to collapsing, thus causing other issues, such as bent pushrods. Symptoms you might experience as a consequence include a decrease in power or performance. The only real fix is to replace these lifters outright. Not to mention, needing to replace the damaged pushrods. If your GMC is new, it may be covered under warranty.

Although, if you’re buying an older GMC (or Chevy, or other GM vehicle that features AFM), this is a big deal, since fixing it is rather costly… $1,000 or likely more. If you’re looking to prevent this from happening at all, some owners opt to disable or delete the AFM entirely. This is a pretty expensive procedure too, but at least it’ll prevent collapsed lifters and bent pushrods.

2. Excessive Carbon Buildup

Aside from the AFM, the adoption of direct injection in GMC’s L86/L87 6.2-liter V8 engines has also proven problematic. Just like on a lot of other cars, direct injection here has caused a carbon buildup problem with the GMC 6.2 engine. This is different from the older GMC/Chevy/GM engines, which use port injection. The fuel delivery was not as precise back then.

However, the side effect was that the design was good enough to clean off the intake ports. Thus, preventing carbon buildup. On the other hand, direct injection doesn’t manage self-cleaning as effectively, which causes carbon buildup to occur. In some cases, this could happen every 60,000 miles. And, if not fixed, it ruins the performance and efficiency of your truck.

The only way to fix this would be to clean your intake valves with walnut blasting. Or, you could take it to a dealership or service center, and let them clean it off with special machines. It’s not an expensive repair job either, with the basic carbon buildup cleaning process costing you $500 or more. But hey, this ought to stave off carbon buildup for another 60,000 miles.

3. Direct Injection Pump And Fuel Injectors Failing

Another downside of this direct injection system that adds to the pile of GMC 6.2 engine problems is the direct injection pump and fuel injectors regularly fail. These things have very tight tolerances. So, if you fill up with gas that has even microscopic impurities, it will fail. If you’re buying an old GMC truck, make sure to check the pump and the injectors.

Otherwise, it’ll cost you quite a bit of money to get all this sorted out… $2,000 or so is a good estimate. Between the carbon buildup issues and the easily worn-out pump and injectors, some owners have even contemplated mods to swap out the default direct injection system for old-school port injection. It’s not easy, but some reckon it’s a feasible project.

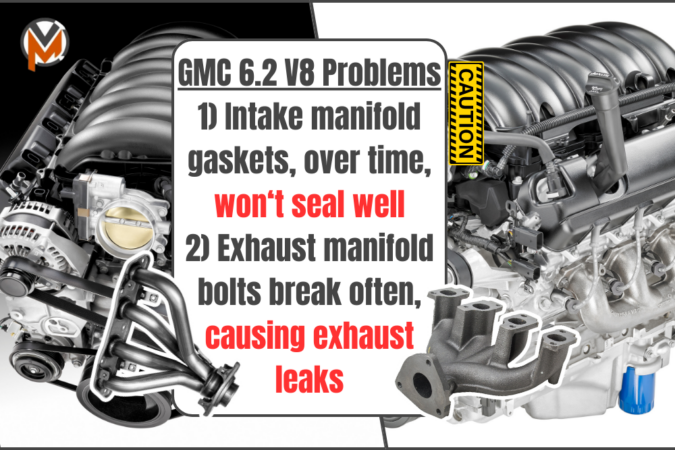

4. Intake Manifold Gaskets That Leak

Other than that, this is mainly a problem with higher mileage GMC vehicles with the 6.2 engine, but there are noteworthy issues with the intake manifold gaskets. The cause is found to be the material these intake manifold gaskets are made of. Over time, the material hardens, made worse by age, heat exposure, and regular wear and tear, and now, they won’t seal well.

When there is not enough of a good seal in the intake manifold, there’ll be a lot of unmetered air entering the engine. This means that you’ll often see a check engine light (CEL), not to mention the performance impact it has on the engine. A lot of unmetered air in the engine makes it run lean. Thus, causing your ECU to automatically dump more fuel into the engine.

This ultimately worsens your fuel economy and has other performance impacts and concerns regarding the engine’s longevity. The only good thing about this problem is that it’s not that expensive to fix. You could even do it yourself… The intake manifold gasket is on top of the engine. And, you only have to remove a few components to get to it, before replacing it.

5. Broken Exhaust Manifold Bolts

Another notable GMC 6.2 engine problem is the exhaust manifold bolts, which are prone to breaking. Unfortunately, these aren’t cheap or easy to fix. What is bad though, is that you have to replace them if you want to prevent exhaust leaks from happening. These leaks can cause exhaust gases to get inside your cabin, not to mention causing other issues.

One of those side effects is the check engine light (CEL) turning on. This is activated because the O2 sensor is getting incorrect airflow readings. This lets your truck’s computer know that something is wrong. Another common symptom that you might notice with broken exhaust manifold bolts is a hissing sound, normally from the front, where the engine is.

Repairing this is probably going to be pretty expensive. This is because a lot of parts have to come off for a mechanic to be able to reach the engine. You can’t realistically expect this to get sorted under $1,000 or more since there’s a lot of work required. As a whole though, despite these issues, in general, the GMC 6.2-liter V8 engine is comparatively really reliable.

The info on the hemi 6.4 being more hp and torque then gm’s 6.2is wrong. Hemi is 410/429 where gm that’s actually underrated is 420/460. Just wanted to correct that was all. If you drive either or you fell a big difference. Gm 6.2 aside for dfm issues is a very stout motor. Also carbon on the intake valves has been virtually eliminated with updated valve cover and valley breathing on the L87 design. I had a previous L86 and it didn’t seem a issue either.

Thanks Benjamin, now updated.

2022 High Country 6.2 ourchased November of 2022 New. ar 3k miles the fuel injectors needed to be replaced nd at 8115 miles (August 10 months of ownership) blown lifters