The cost of an engine rebuild is lower than that of an engine replacement. There are warning signals that your engine needs to be rebuilt. But how much do engine rebuilds cost?

One of the best parts is that rebuilding an engine can be fantastic, and a less expensive option compared to replacing the engine. Let’s discover more about how much do engine rebuilds cost.

Without further ado!

Engine Rebuild Cost

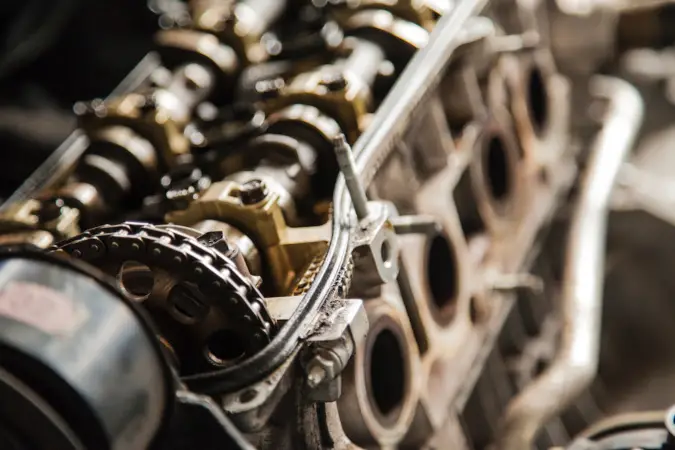

The precise pricing will depend on what you need to do if it turns out that the degree of the damage necessitates an engine rebuild. To assess how extensive the damage is, they will first remove the head.

In some cases, they might just glaze and hone the cylinders and replace the piston rings. If they discover that the issue is far more serious, they will need to lift the block out completely.

How much do engine rebuilds cost start to increase at this point. Any components that fall short of manufacturer expectations will be replaced or fixed. You will also have to prepare the cylinders for the installation of the new pistons.

Some part, which includes the main bearing, freeze plugs, and the rod, need replacing as well. Additionally, the task can need machining and finishing repairs, which frequently results in it being transferred to an expert.

How Much Do Engine Rebuilds Cost – How Much You’ll Need To Pay

So, how much do engine rebuilds cost, it will cost $200 to $300 for replacing piston rings and polishing the cylinder walls. However, this increases significantly if the engine needs to be hauled out.

Much of the cost will depend on which components need to be fixed or replaced once it has been lifted out.

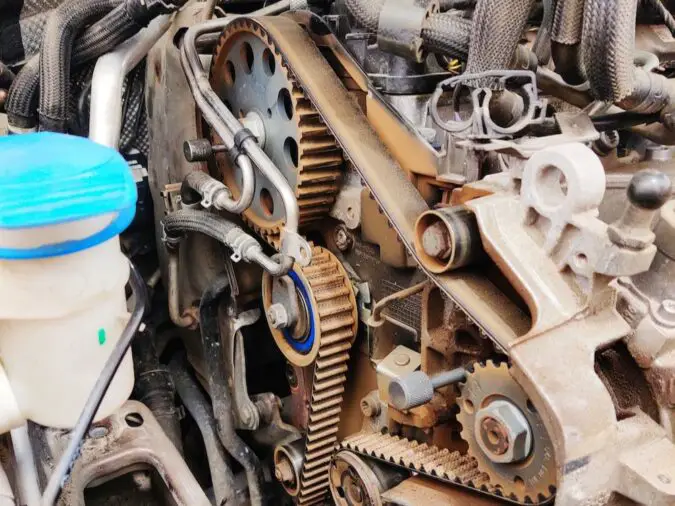

Consider a timing chain, which can cost up to $1,000 to replace.

Add an extra $1,000–$2,000 for the price of new lifters, journal bearings, and water and oil pumps.

In terms of labor costs, the majority of shops charge $50 to $100 per hour.

The actual task often takes 10 to 20 hours to accomplish. You’re looking at labor costs of between $500 and $2,000 when you add these up.

In the end, the expense of rebuilding an engine ranges from $2,500 to $4,500.

Now let’s go through how your car’s make and model affect the price of an engine rebuild.

Rebuilding An Engine

Now that you understand how much do engine rebuilds cost, note that there are numerous instances where an engine rebuild is preferable to simple part repairs.

This is whether it’s to give your engine new life and restore it to like-new condition, to modify it for the best performance, or for pleasure in a classic automobile.

With the help of this comprehensive tutorial on how to rebuild an engine, it is still possible to finish the difficult and scary task of rebuilding an engine in your garage.

How Much Do Engine Rebuilds Cost, Phase #1 – What You Will Need

You’ll need a few things if you want to strip your current engine down to the bare block and rebuild it.

- Engine overhaul tools

- Tool for camshaft bearings

- Tool for sharpening cylinder bores

- Reamer for cylinder bore ridges

- Ring compressor for pistons

- Protectors for rod journals

- Producer of silicone gaskets

- Timing-gear remover

- Ratchet wrench

- A wheel chock

- Engine component lubricant

- Oil that displaces water

- Basic set of hand tools

- Powered drill

- Brass knuckle

- Compressed air

- Air hose and a blowgun

- Fender guards

- Jack postures

- Flashlight

- Masking Tape

- Indelible marker

- Drain pan for oil (at least 2)

- To store and arrange hardware and pieces, use plastic sandwich bags and boxes

- Service guide

- New parts for rebuilding an engine

How Much Do Engine Rebuilds Cost, Phase #2 – The Rebuilding Process

Let’s take a look at the procedures to follow for a thorough vehicle engine rebuild.

Step 1. Take The Engine Out

Place the car close to your hoist.

You’ll require a sizable, well-lit garage with a level surface and enough space for you to set up your hoist and move around it.

Step 2. Remove The Engine Cover

To make it easier to locate the hinge bolts later, mark them. Have a helper aid you as you gradually loosen them and slide them off.

Note that certain hoods feature electrical connections for mounted headlamps, signal lights, and fog lights. Also, unplug them.

Step 3: Remove The Exterior Engine Parts From The Engine

It is crucial to remember that before you do anything else, you must unplug the battery’s ground line for safety reasons.

After that, drain the radiator and coolant pipes. The metal clamps, which are more challenging to replace than rubber hoses, should be handled with extreme caution.

Remove the fan shroud and radiator.

Loosen the alternator, tension assembly, cooling fans, and belts.

Fuel and intake air supply connections should be disconnected. Drain the fuel and release the pressure in the fuel system before disconnecting it if your automobile has one that is pressurized even when the engine is off.

Considering the numerous components of an engine, it is advised that you take close-up images and label the parts with markers for future reference. This will make later reassembly much simpler.

Step 4: Disconnect The Motor’s Electric Connections Completely

To separate the transmission, you must first disconnect all the electric connections that you can see to the transmission and remove the exhaust manifold.

The spark plug wires may wait until later.

Step 5: Unbolt The Bell Housing Of The Transmission From The Engine

The transmission is supported from below by additional jack stands once the car has been raised in the air and placed on jack stands.

Before you remove the bolts, support the transmission with anything as there won’t be anything to hold it in place once they’ve been loosened.

As long as it can be supported securely while the engine is removed, the transmission itself usually doesn’t need to be taken out of the car.

Step 6: Remove The Engine Using The Hoist

Connect the hoist to the largest bolts near the top of the engine or the lifting points on the cylinder heads, and then slowly adjust the leveler to begin lifting the front.

Step 7. Take Apart The Engine Block

Obtain the owner’s manual for the car in question.

To understand all the necessary specifications and specifics required to rebuild your specific engine, you must carefully review the instructions provided by the engine manufacturer.

To be sure the engine you think you are working on is the engine you are working on, check the ID and casting numbers on your engine.

Step 8. Examine The Engine

Check the block for any indications of overheating, cracking, or scorching.

Examine the numerous plugs and joints between the components for any fluid that may be escaping.

Additionally, look for any extra gasket sealer that may have remained after earlier repairs.

Step 9. Examine The External Parts

By spinning the pulley and listening for any odd noises, check the alternator belt for signs of wear. Next, apply some pressure on the distributor to check for any symptoms of slackness.

Step 10. Examine The Clutch Assembly For Wear

Be cautious when removing rusted exhaust manifold bolts or studs to avoid injuring them. Lubricants can be helpful. Otherwise, you may require heat to release highly resistant fasteners.

Step 11: Take The Remainder Of The Engine Apart

The oil pan and valve covers should come first, followed by the cylinder heads. When lifting the cylinder heads, take care not to break or bend the lifter rods because this will require replacement.

Step 12: Check The Cylinder Bores

The likelihood of rebuilding being effective will be low if the cylinders are too worn. To measure the bore diameter, you might wish to use a micrometer.

Alternatively, by examining the cylinder ridge, you can get a fair sense of how much the cylinder walls have worn down. Because the rings don’t ascend all the way to the top of the bore, the ridge is the spot where the cylinder wears out the least.

The cylinder wear ought to be less than this.

The original pistons can typically be reused if the wear is less than 2/100 of an inch; otherwise, the engine needs to be bored out and oversized pistons must be used.

Then, using a cylinder reamer, remove the ridge on the cylinders close to the top of the bore. This will make it possible to remove the pistons without causing harm and to reinstall the pistons with new rings.

Step 13: Remove The Piston And Rod Assemblies

To stop the rod ends and bolts from rubbing the engine block, remove the rod caps from the rods and install rod journal protectors on them.

Keep them as numbered pairs or matched sets by replacing the identical rod cap on the matching rod after it has been removed.

Keep the components marked so you can subsequently put them back in the appropriate cylinder from which they were taken.

Step 14: Remove The Crankshaft And Examine It

Utilizing crank mounting plates, remove the crankshaft. Keep old main bearings clean and maintain order by checking them for wear. Take off the auxiliary drives, balancer shafts, and camshaft.

Maintain order because you will need to put everything back in its proper place. Carefully remove the cam bearings while keeping an eye on their location.

Look for any symptoms of overheating as well as cracks. Measure the journal diameter, out of round, taper, and run out of the crankshaft.

Compare this to the shop manual’s measurements.

Mark any mismatched dimensions, then have the crankshaft refinished at a machining shop. Then take another measurement of the crankshaft so you can replace the bearings and get the crank-to-bearing clearance to the required level.

How Much Do Engine Rebuilds Cost, Phase #3 – Complete The Breakdown

Remove everything that connects to the engine block’s outside surface, including the core plugs, brackets, and guide pins.

1. Check For Cracks In The Engine Block

First, squeeze the valve springs.

Use a valve spring compressor to compress the valve springs. After that, take off the valve keepers to gradually let the valve spring unwind.

Remove the valve springs and shims after you’ve been able to remove the compression tool. Keep these parts in the proper order once more.

2. Time To Remove The Valve Head

You must clean the valves and valve head for each valve to eliminate any carbon buildup or debris. To avoid scratching the guides, do not try to push them out.

To find any cracks, use a dye.

3. Examine Every Valve Head

In order to fix it at the machine shop, look for any flatness that is not according to specification. Examine the guides for excessive wear and look for valve seat recession. Don’t forget to look out for worn valve stems that you measure to be outside of tolerance.

4. Replace Worn-Out Keeper Grooves

Replace voids with excessively thin margins.

Size, tension, and squareness: Replace any springs that have gone past their recommended lifespan.

5. Replace The Outdated Valve Guides

All valves that won’t require replacing will be refaced in addition to having the recessed valve seats replaced and machined. After that, apply engine oil to the valve stems and install valve seals.

How Much Do Engine Rebuilds Cost, Phase #4 – Engine Block Reassembly

We have reached the halfway point of the engine rebuilding process. Remember the steps from the disassembly and proceed backward for the reassembly.

This is why maintaining pictures, labeling things, and organizing your pieces will make the process much easier for you.

1. Cleaning The Components

You need to totally disassemble the engine at this stage. Then, wash the parts with warm water and a water-soluble detergent. Lay out all of the parts that you will reuse and thoroughly clean each component. Then use compressed air to blast them dry.

2. Clean The Engine Block

To get the block and heads ready for reassembly, repeat the cleaning and drying procedures. Check the heads and the block for any signs of damage.

3. Attach The Main And Crankshaft Caps

Install the camshaft after applying high-pressure lubricant to the camshaft bearings. Snug the caps and then torque them onto the block from the center outward because they are sensitive to position and direction. Check to determine if the crank binds by rotating it.

4. Correctly Install The Timing Belt Or Chain

Set the degree wheel accurately on the cam, the crankshaft/piston timing, and the appropriate valve timing sequences for the engine’s intake, compression, power, and exhaust strokes. Align the timing markers at Top Dead Center.

5. Install Fresh Pistons, Rings, Gaskets, And Seals

Check the OEM clearances at the piston ring ends. If the rings are too large in diameter, they will be overly tight and risk binding and possibly breaking when the engine heats up, whereas rings that are too small will have excessive end gaps.

6. Install The Head Gasket

Make sure to install the head gasket properly because it may be directional.

Install fresh valve heads next. After applying Original Equipment Manufacturer (OEM) lubrication or sealer to the bolt threads and washers, torque the bolts down three stages using the OEM-recommended pattern.

7. Install A New Valve Train

Always lubricate the components as you install them, and make any necessary valve adjustments.

How Much Do Engine Rebuilds Cost, Phase #5 – Putting The Engine Back In

First, reattach the engine to the hoist.

It should now be completely put back together and ready for installation. Reinstall the engine in the car by mounting it first on your hoist.

Keep in mind how you removed it previously; you are now only working backward.

Reconnect the engine in step two.

Reconnect all the hoses, harnesses, and electrical connectors, in the same sequence that you removed them. Refill the antifreeze and engine oil next.

Make final checks to ensure that each component is in its original location. The engine ought to now be ready to start. Now, follow the exact instructions for engine start-up and break-in in your handbook to guarantee that you receive the best performance and lifespan out of your rebuilt engine.

Cost To Install An Engine

The size and complexity of the engine in question, the shop rate at the facility you have selected to perform the job, and whether you choose to replace it with a used, refurbished, or new engine all have a role in the answer to this question.

The starting price for a new engine is approximately $4,000 for a 4-cylinder, $5,500 for a V6, and $7,000 for a V8. Based on the brand of the automobile and the complexity of the engine, prices rise from these numbers.

It goes without saying that how much do engine rebuilds cost for a performance engine or for an imported luxury car will be more than a stock engine for a local economy car.

It is possible to buy a used engine for much less, often as little as $400 to $700. The age of the vehicle, mileage on the used engine, and transportation expenses from the engine’s location are the key variables influencing the pricing of these engines.

The cost of shipping is not part of the pricing but you need to include it because the business will charge you for it.

New Versus Used Engine

Away from how much do engine rebuilds cost, note that the main danger with buying a secondhand engine is the labor cost you will incur. Although a junkyard or other supplier of used parts frequently provides a brief warranty on the engine itself, it excludes the work performed by the shop installing the motor.

If the newly installed engine doesn’t start, you’re still responsible for paying the mechanic’s time and any additional billable hours needed to get it operating (unless the failure is the result of the mechanic’s error).

By buying a rebuilt engine, you can reduce this risk. You can restore an engine’s operating tolerances after rebuilding it. Although there is a replacement of all the seals and gaskets, this does not mean that the engine is brand-new.

Instead, worn moving parts have been changed. You can be sure that the engine will function properly when installed and that its anticipated lifespan has been increased. It frequently has a stronger warranty than what you’d obtain from a provider of used parts.

This assurance does have a price. The cost of a new engine installation will be between $2,500 and $3,000, which is still significantly cheaper than the price of a new engine when compared to a used 4-cylinder engine that costs $1,000 or less. Beware of these scams targeting repair shops.

Labor Cost For Engine Replacement

The quoted shop time for a normal engine is 10 to 12 hours. A professional technician may give you a quote for as low as 8 hours on a simple engine, whilst larger work may take as long as 15 hours.

The first time frame should contain the majority of the quotes. By dividing the quoted number of hours by the shop rate, one can calculate the labor costs. The hourly shop rate might range widely, from as little as $90 to more than $150.

Accordingly, labor costs for a typical engine replacement can range from $1,100 to $1,800 using a low-end shop rate of $110 and a high-end shop rate of $150.

Additional Costs

Shop supplies are the first potential expense on the list for an engine replacement. Subsequently, your new engine will need coolant, oil, as well as other fluids which help to keep it running smoothly, but it shouldn’t cost more than $100.

Also excluded from engine replacement are all the bolt-on components including the fuel pump, water pump car, belts, hoses, intake as well as exhaust manifolds, pulleys, and tensioners.

Thus, the cost of labor to replace these parts is frequently more than the cost of the part—in some cases noticeably higher. However, since you must take out these components and put them back together after replacing the engine, the additional labor costs for installing a brand-new water pump are not in the cost.

Discuss replacement options for auxiliary parts with your mechanic and take as many steps as your budget will allow.

Frequently Asked Questions

How Much Does It Cost To Rebuild An Engine

The average cost of parts and labor for an engine rebuild is somewhere between $2,500 and $4,000. Simply replacing bearings or seals as well as, obviously, removing and reinstalling the engine are possible components of this form of engine repair.

How Much Does A New Engine Cost

For most vehicles, an engine replacement will cost from $3,000 to $5,000. The cost could even rise up to $6,000 to install an extremely top-performing and sophisticated engine. A normal vehicle with a 4-cylinder engine will cost around $4,000 for a replacement engine.

Is Getting New Engine Like Getting A New Car

No getting a brand-new engine isn’t like getting a new car. This is simply because while the engine is new and doesn’t have miles on it, the rest of the car has endured many miles on it and will not be like a brand-new car.