What are engine lifters? Hydraulic valve lifters, also known as hydraulic tappets, are tiny cylinders located directly next to each engine valve in your car. It guarantees that your car operates effectively and quietly. A lifter tick or tapping noise in the engine is caused by the lifter mechanism wearing down over time, particularly if there is insufficient or unclean oil.

If you ignore this noise or other indications that your lifter is defective, the issue might worsen and endanger your car. We’ve compiled a list of problematic hydraulic lifter symptoms you should never ignore to help you avoid the costly repercussions of doing so. Let’s discuss what are engine lifters, lifters ticking fixes, and engine lifters repair costs.

- What are Lifters?

- How do they Operate?

- Solid vs Hydraulic Lifters

- Rockers Arms and Lifters

- Bad Lifter Symptoms

- Lifter Tick vs Rod Knock

- Why do Lifters Fail?

- Engine Lifters Cost?

- Can you Fix Collapsed Lifter?

- FAQs

Engine Lifter

The engine lifters in your car’s engine assist in controlling the valves. Different types of engines employ a range of lifter designs:

1. Lifters In OHV Engines

The parts of an overhead valve (OHV) engine that follow the curves of the camshaft are referred to as “lifters” in the past. The rocker arms open and close the engine’s valves when the camshaft rotates to work the lifters, which act on a number of pushrods. The lifters also keep the engine’s valve train lash in check.

Solid (mechanical) or hydraulic lifters are both acceptable. It is occasionally necessary to mechanically adjust the valve train lash when using solid lifters. Conversely, hydraulic lifters don’t require routine adjustment because they rely on pressurized engine oil to internally adjust the lash on their own.

Additionally, there are roller lifters and flat lifters. Flat lifters, which are often present in antique cars, have a comparatively flat face that slides on the camshaft. Roller lifters, on the other hand, feature a wheel-like roller that follows the shape of the camshaft. Almost all OHV engines today come with roller lifters because they have since the 1990s.

2. Engines With OHC Lifters (Lash Adjusters)

These days, lifters may also be used to refer to the hydraulic lash adjusters used in overhead camshaft (OHC) engines. The valvetrain parts’ spacing is adjusted via the lash adjusters. Each lash adjuster may be placed between the cylinder head and a camshaft follower, inside a bucket over the valve, or integrated into the rocker arm, depending on the engine’s layout.

3. Modern Lifter Technology

It’s also crucial to note the modern lifter technology used in engines today. A cylinder deactivation mechanism in some cars nowadays can turn off half of the engine’s cylinders to save gasoline (more so if you know how to save gas). The valves in the deactivated cylinders need to be closed for the technology to function properly.

One of the methods used by automakers to deactivate the valves is the use of unique collapsible lifters. The powertrain control module (PCM), a common name for the engine’s computer, modifies the status of the lifters by sending oil pressure through solenoid valves to those components. Large OHV engines frequently have collapsible lifters.

How Do Engine Lifters Work

1. Movement

The lifters operate the exhaust and intake valves. The lifters can move up and down due to the cam’s egg-shaped lobes. The lobe’s narrow, short end is the cam’s heel. The lifters move the valves into the open or closed position by being pushed up and down by the cam as it rotates. In non-overhead cam engines, the rocker is moved up and down by the rocker’s reciprocating movement with the push rod by the lifters. The front of the rocker moves the valve.

2. Modifications For Solid Lifters

In contrast to hydraulic lifters, solid lifters do not compress. If your vehicle has solid lifters, which are typically used in racing applications, you must adjust the lifters regularly to keep the required tolerances.

3. Hydraulic Lifters

Adjustments are not required for hydraulic lifters. They receive an oil “pump up” before being installed in the car. Compared to solid lifters, hydraulic lifters have more individual parts. They are equipped with a plunger and a spring that is housed inside the lifter body. A check valve ensures that the oil reservoir on the plunger is always filled. If the oil pressure drops, the lifters may not receive enough oil, become noisy, or stop functioning.

4. Rolling Lifters

Another type of lifter is a roller lifter. These are roller-equipped hydraulic lifters. The roller rides directly on the camshaft on both engines with and without overhead cams. Less resistance is created as a result, increasing horsepower.

Solid Vs Hydraulic Lifters

Solid vs hydraulic lifters? The term “solid lifter” also applies to mechanical valve lifters. They are solid metal objects with accurate measurements. The valve train needs to be modified to take wear into account as it deteriorates. The engine continues to run smoothly and quietly as a result. Adjustments must be made frequently. This can occur every 15 or 30 thousand miles on some engines.

When the engine is operating, oil is poured through hydraulic valve lifters. They self-adjust as you wear them. Hydraulic valve lifters have a lifespan of well over 100,000 miles in an engine with good maintenance. Additionally, they operate more softly than sturdy lifters. They will deteriorate over time, though.

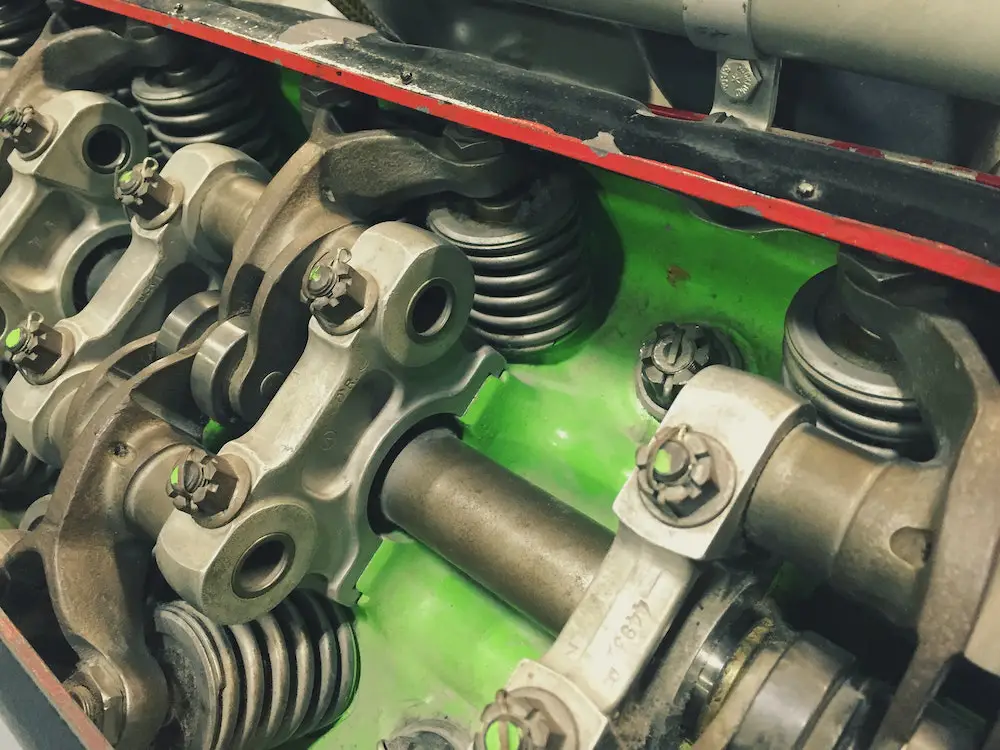

Rocker Arms And Lifters

The camshaft’s spinning lobe raises and lowers one end while acting on the valve stem with the other end. Direct tappets are frequently replaced by these rocker arms, which are particularly prevalent in dual overhead cam motors.

Bad Lifter Symptoms

A bad lifter will exhibit some indicators to alert the driver of an impending issue, just like every other engine part does. Engine misfiring and unusual noises are the most typical signs of a faulty hydraulic lifter. Additionally, it will turn on the check engine light. Let’s examine the bad lifter symptoms.

What Are Engine Lifters, Failure Symptoms #1: Engine Ticking Noise

Excessive ticking engine noise is a common symptom of faulty lifters. For instance, a jammed or broken hydraulic lash adjuster will result in an odd noise coming from the cylinder head. You will then hear the sound of metals rubbing against one another.

It is obvious that broken lifters will be banging into one another. These loud, irritating noises are audible while idling and while driving. However, as you speed up the car, the noise will get louder as the hydraulic lifters strive to activate more quickly. The lifter itself may be at fault if the oil doesn’t cause the issue. You will hear an engine ticking noise that can worsen with time if the lifter is broken and not moving as it should.

What Are Engine Lifters, Failure Symptoms #2: Engine Misfire

You may legitimately inquire whether a poor lifter may result in power loss. The rocker arms are connected to the pushrod at that point, which aids in shutting and opening the intake and exhaust valves. The intake and exhaust valves won’t operate as intended if the lifters aren’t working properly. The engine’s combustion process will be disturbed.

Poor lifters consequently lead to misfires. However, a number of things can lead to engine misfiring. A persistent engine malfunction could leave you stuck in the middle of nowhere. To identify and fix the problem, it is crucial to call a service professional.

What Are Engine Lifters, Failure Symptoms #3: Check Engine Light

The check engine light on the dashboard indicates a problem with any sensors, electrical, or mechanical parts of the vehicle. For instance, the powertrain control module is in charge of many auto parts. The PCM will activate the check engine light to alert the driver if any of these parts fail. Several dashboard warning lights may come on as a result of a bad or damaged lifter. But one thing is certain: the check engine light will come on.

What Are Engine Lifters, Failure Symptoms #4: Dead Cylinders

Pushrods can be bent or broken by poor lifters. A pushrod is a cylindrical metal tube that moves valves by transmitting the motion of hydraulic lifters mounted on cams. The lash adjusters’ main function is to ensure that the pushrod always moves in the same direction. Therefore, the push rods will be affected if the lash adjuster becomes stuck or breaks. When the pushrod breaks or bends, the accompanying cylinder will stop functioning.

A cylinder is said to be dead when it is no longer working. The engine performance will be considerably decreased. There will also be a change in the engine noise. It is essential to remember that a number of additional circumstances can result in dead cylinders.

But as soon as you notice a dead cylinder, have a qualified mechanic examine the vehicle and fix the problem. Ignoring a dead cylinder and driving with it for an extended period of time will cause harm to related components and finally lead to an engine breakdown.

Lifter Tick Vs Rod Knock

What’s the difference between lifter tick vs rod knock? When an engine’s connecting rod makes touch with another surface, rod knock occurs, and valve covers bring lifter ticks on. Without prompt maintenance and repairs, both sounds are bad for your engine and could cause serious issues. It could be challenging to hear these noises, especially if you never rev your car.

Lifter ticks often manifest as a faint, repetitive ticking from your engine, whereas rod knocks are significantly louder. Lifter ticks cannot produce the knocking or clicking sounds that rod knocks produce. The rhythms of lifter ticks and rod knock frequently diverge. Ticks are quick and repetitive, whereas bangs are slower and louder as engine activity increases.

Why Do Lifters Fail

Lifters are built by automakers to endure a very long period. Unfortunately, some lifters malfunction and need to be replaced. You could then be wondering what causes lifters to degrade. Here are some of the most typical causes.

What Are Engine Lifters, Causes Of Failure #1: Condition Of Engine Oil

If the oil level is insufficient to flow to the cylinder head, lifters will starve to death. Lifters will experience a lack of lubrication if the oil pump is unable to temporarily push enough oil to the head cylinder due to low oil levels (to learn more, check out our guide on how much oil does my car need). Without oil to absorb the cushion from the pushrod or tappet, hydraulic lifters will malfunction. Corrosion also affects solid lifters, and the camshaft lobe may exhibit corrosion.

The aeration or bubbles that result from too much engine oil in the crankcase will make the oil lose its ability to lubricate. Additionally, contaminated oil may obstruct or clog the tiny holes on the pushrods, hydraulic lifter orifices, or both.

What Are Engine Lifters, Causes Of Failure #2: Poor Quality Oil Filters And Screens

Every component of the engine, especially the upstream, can become clogged by an oil filter that is of poor quality or that has been in use for a long time without being replaced. A blinking or steady check engine light or an oil pressure light on the instrument cluster will be present if you are in any of these circumstances. Oil pressure is decreased and is prevented from reaching the valve train sections by a dirty or blocked oil pump pickup screen.

What Are Engine Lifters, Causes Of Failure #3: Incorrect Viscosity Rating

There are many grades of motor oil. Additionally, automakers advise using a particular grade of oil in each engine. Using the incorrect oil grade or viscosity decreases engine performance and accelerates friction and wear.

What Are Engine Lifters, Causes Of Failure #4: Old Engine And Poor Maintenance

Lack of maintenance will result in sludge buildup and lifter wear, particularly on older engines. The engine oil is necessary for the correct operation of the valve train, particularly the pushrods and lifters. Pushrod, lifter, and cam lobe bottoms will probably become worn in vehicles with 75,000 miles or more of mileage and contaminated engine oil.

Engine Lifters Repair Cost

Because there are so many variables, determining the cost to replace an engine lifter is not as simple. Obtaining a lifter replacement cost estimate is actually quite simple if you decide to replace just one damaged lifter. But just like spark plugs, it’s best to just replace them all because if one breaks, others will probably follow quickly. A lifter alone might cost anywhere from $5 to $30. However, depending on the engine, this can vary significantly if you’re replacing all the lifters in it.

For the most part, each valve has two lifters. As a result, you might need to replace two lifters, 32 lifters, or something in between. It can become pretty pricey when you factor in the cost of gaskets, fasteners, and other components.

An alternative is to buy a complete lifter replacement kit. An aftermarket kit will be less expensive than buying individual OEM parts from a dealership, but you also need to take quality into account.

Additionally, labor costs won’t be cheap. Again, depending on the engine, it could take three hours, ten hours, or anything in between. Using the average, you’re looking at somewhere between $100 and $150 per hour of labor.

If you use an average hourly wage of $100, the cost of labor alone will be between $300 and $1,000. Giving an average price when discussing the complete lifter replacement cost (parts plus labor) is challenging. However, as an illustration, expect to pay somewhere between $1,000 and $2,000 for a typical V8 engine with 16 lifters, depending on the quality of the parts and whether you go to an independent mechanic or the dealership.

Lifters Ticking Fix

Use the following advice to lifters ticking fix:

What Are Engine Lifters, Fixing Lifter Ticks #1: Check The Engine oil

Your top concern should be keeping your car maintained, which is why you should change the engine oil and filter frequently. Lifter ticks may develop if you let contaminated oil continue to circulate through the system. Even when the system has clean oil, there may not be enough.

Check the levels in between oil changes, and top off as necessary. Always use the appropriate type of oil for the season and your car. Depending on the weather in your area, you might need to change your oil at different times of the year.

What Are Engine Lifters, Fixing Lifter Ticks #2: Use A Noisy Lifters Additive

You might also think about adding an addition to maintain the oil’s quality. Numerous high-quality noisy lifters additives are available to clean the engine parts and maintain the system’s proper lubrication. The majority of lifter tick oil additives help the valves, rocker arms, pushrods, and valve lifters.

You should pour the noisy lifters additive in if your formulation calls for it when changing your oil. A premium oil addition, such as Liqui Moly or Marvel Mystery Oil, can enhance engine oil quality and clean the lifters. These chemicals also clean rocker arms, valves, and other engine components. Since it’s a simple fix, this is the best-case situation.

What Are Engine Lifters, Fixing Lifter Ticks #3: Change The Lifter Spacing

If there is nothing wrong with the lifter but the noise still occurs, have a qualified mechanic adjust the distance between the lifter and other engine parts. The proper lifter spacing is often stated in vehicle manuals.

What Are Engine Lifters, Fixing Lifter Ticks #4: Change The Lifter

The worst-case scenario is that a valve lifter needs to be replaced. You are left with no choice except to purchase a new one if it breaks. You might just replace them all at the same time because the defective lifter might have increased the wear on the others.

If you have an older engine with solid lifters, there are occasions when the valve lifter can easily be adjusted to stop ticking. Any problems with the clearance between the pushrods, camshafts, and valve lifters can be detected by a qualified shop.

Collapsed Lifter

To prevent further harm to your engine, replace the malfunctioning hydraulic lifter in your car as soon as you can. A defective hydraulic lifter will typically just need to be replaced. Depending on the make and type of your car, you might only need to replace one damaged hydraulic filter.

However, many mechanics advise replacing all lifters at once when one fails because it’s typically a good sign that the others will shortly follow. Depending on how old it is, you can think about utilizing remanufactured lifters in your car rather than new ones. Refurbished hydraulic lifters will be far less expensive and typically perform adequately for older, pre-owned vehicles that might not have many more years of useful life left in them.

FAQs: What Are Engine Lifters

What Is A Lifter In An Engine

The lifter is a cylinder that separates a car’s camshaft and the intake and exhaust valves. The valve is momentarily opened as the camshaft actuates as it passes over the top of the lifter. Additionally, each has a distinct lifter since the intake and exhaust valves must open at various times.

Why Is My Car Ticking

Fuel injector noise alone may be the cause of an engine ticking sound. Even though certain injectors emit a sound as their valves open and close, this sound is typically more buzzing than it is a distinct tick. The noise is typically most audible on direct-injection engines and is not a reason for alarm. Low oil pressure is the most frequent cause of engine ticking noise. This is a sign that important engine parts are not receiving enough lubrication. Low oil pressure in your engine could be the result of low oil levels or an internal engine issue. Noises like ticking or clicking may also indicate worn lifters or cam followers in the valve train. Due to having too much clearance, a worn camshaft lobe or broken valve spring will result in these noises. Given the wide range of potential causes, these can be challenging to diagnose on your own.

How To Fix Lifter Tick

Your top concern should be keeping your car maintained, which is why you should change the engine oil and filter frequently. Lifter ticks may develop if you let contaminated oil continue to circulate through the system. You might also think about using additives to maintain the oil’s greatest qualities. Numerous high-quality oil additives are available to clean the engine parts and maintain the system’s proper lubrication. The worst-case scenario is that a valve lifter needs to be replaced. You are left with no choice except to purchase a new one if it breaks.

How Long Can You Drive With Bad Lifters

If you have faulty engine lifters, you shouldn’t travel more than 100 miles; instead, use those miles to get your automobile to the technician. The inside section of the lifters may completely collapse if you drive on them for an extended period of time, damaging the camshaft as they come into touch with it. When a lifter malfunctions, the interior portion of these lifters may descend all the way to where they make contact with the camshaft. Therefore, the lifter’s roller presses against the camshaft and can potentially harm it to the point where a replacement is required in the next 10,000 to 15,000 miles.

What Causes A Lifter Tick

To ensure that the engine operates effectively, the oil must provide lubrication. If the engine oil is not changed, dirt and sludge will accumulate and clog the engine lifter, causing it to click. As a result, you should be careful to change your engine oil regularly. Even though it is not the main reason for engine clicking noise, a broken lifter may be the issue. The only solution if your lifter was defective was to replace the lifter entirely. Additionally, removing an engine lifter is incredibly difficult and will take several hours of highly specialized labor. The consensus among experts is that you should take good care of your car if you want it to last longer. This also includes performing regular and necessary vehicle maintenance. Even if you are performing routine maintenance on your car, you might not be selecting the best personnel or supplies for the job.

How To Fix Ticking Noise In Engine

How to stop an engine’s ticking noise depends on several factors that can create it. Oil has a role in some engine ticks. You need to change it when it’s contaminated. Special additives are used to purify engine oil. Along with cleaning the oil, it can also clean other engine components including lifters, rocker arms, valves, etc. The internal combustion engine’s head is where spark plugs are located. They won’t sit properly if worn out, allowing gases to bypass and make the engine click. You need to change the defective spark plugs if you want to get rid of this licking noise.

How Do Hydraulic Lifters Work

Oil under pressure enters the lifter body through a hole and flows into a small channel. This oil flows freely out the other side after entering the internal lifter cylinder. The channel is closed when the cam squeezes the lifter piston. In order to allow gas to exit the cylinder, this briefly seals the valve open even when there is high pressure. The lifter piston can raise and restore oil flow when the cam reaches its apex. As a result, the valve closes abruptly, maintaining the proper engine air pressure.

How To Quiet Noisy Lifters

If you use oil that is not appropriate for your automobile, such as oil that is heavier or lighter than what your car requires, it won’t lubricate well and could lead to issues. The lifter tick noises that are an issue here are caused by poor lubrication of metal parts that come into contact with one another. If you use oil that is not appropriate for your automobile, such as oil that is heavier or lighter than what your car requires, it won’t lubricate well and could lead to issues. The lifter tick noises that are an issue here are caused by poor lubrication of metal parts that come into contact with one another.

How Much Do Car Engines Cost

If you decide to install a replacement, your mechanic will buy a different engine and replace your old one with it. It is difficult to identify engine prices because they vary so widely between manufacturers. Still, your mechanic should provide you with an accurate quote that includes the replacement engine’s cost and labor rates. Expect to pay anywhere between $4,000 for a four-cylinder engine and upwards of $10,000 for a high-performance engine if you’re purchasing a fresh crate engine from the factory and installing it at the dealership.

How To Clean Lifters Without Removing

To remove oils and grime and to release the spring clamp, begin by spraying the lifters. Any residual oil inside the lifter should be disposed of. To remove any remaining oil after spraying the lifters, use a lint-free towel. Fill the valve lifter as full as you can in a container of clean engine oil. Reassemble the ignition coil screws after installing the valve lifter and tightening the retaining bolt. Install the rocker arm, valve cover, and camshaft. Run the engine this time while maintaining the greatest possible RPM. If the noise goes down, your work was successful.

What Is An Engine Valve

Engine valves are mechanical devices used in internal combustion engines to control gas or liquid flow into and out of the cylinders or combustion chambers while the engine is running. They function similarly to many other valve types in terms of blocking or allowing flow. Still, they are simply mechanical devices that interact with other engine parts like rocker arms to open and close in the right order and at the right time.

What Do Lifters Do In An Engine

Lifters are cylindrical parts that move the intake and exhaust valves by riding on the camshaft. To open the valve on pushrod engines, the lifter forces the pushrod into the rocker arm. The lifter presses directly against the valve tip in OHC (overhead cam) engines.

How To Adjust Valves On A Hydraulic Roller Cam

By slightly loosening the adjustment nut and spinning the pushrod until you feel a lash in the rocker arm, you can adjust the intake valve when the exhaust valve on the first cylinder in the firing order just starts to open. Tighten the adjustment nut when the rocker arm and pushrod are no longer slack.

Is Lifter Tick Bad

The lifter mechanism will eventually wear down (especially if there isn’t enough or unclean oil), which will cause a ticking or tapping noise in the engine. If you ignore this noise or other indicators of a broken lifter, the issue might get worse and seriously harm your car.

How To Extend Life Of An Engine With Rod Knock

The purpose of bearings is to maintain the proper motion of the crankshaft and pistons. If the bearings are damaged, the noise will probably be produced. It’s a good idea to inspect the bearings and replace them if necessary when you experience rod knock. The most frequent reason for engine banging is damaged rods. It will be simpler to fix the troublesome parts and stop the engine banging if you can identify the damaged connection rods. Connecting rod replacement is less expensive than engine replacement.

How To Tell The Difference Between Solid And Hydraulic Lifters

While hydraulic lifters are self-adjusting and maintain a constant zero valve clearance or lash, solid lifters are mechanical and need regular adjustments. One may distinguish between the two by examining the valve clearance, also known as a lash, between the rocker arm and the top of the valve stem.

What Does A Bad Lifter Sound like

A malfunctioning hydraulic lifter will create a persistent tapping noise in the engine. The tapping noise in the engine will come on quickly after one another and get worse over time. Depending on the precise problem, the sound may be present whether the engine is hot or cold. You can hear a loud pounding or knocking sound if the lifter is experiencing more serious issues.

Final Verdict: What Are Engine Lifters

What are engine lifters? The hydraulic valve lifter in your car is referred to as a car lifter. It’s a little cylinder connected to the hydraulic valve in your car via a rocker arm rod. Except when it doesn’t, the system functions well. A lifter tick is a phenomenon where the lifter itself generates a loud ticking or tapping noise in the engine.

Depending on the severity of the issue, the lifters may occasionally tick, or they may tick continuously throughout the entire time your car is running. Lifter tick is more common in older and high-mileage cars, although it can occur in almost any car, especially those that haven’t had routine maintenance and repairs.

When your hydraulic lifter develops problems, you can use these suggestions to locate, quiet, and/or repair the problem. Do not wait to take action if your car exhibits any of these signs. Avoiding them could result in engine damage and a more expensive repair.