- How Camshaft Position Actuators Work

- Problems with Camshaft Position Actuators

- Installing a Camshaft Position Actuator

- Different Types of Camshaft Position Actuators

- Diagnose & Repair a Faulty Camshaft Position Actuator

- Advantages of Using An Electronic One Over Mechanical Ones

- Understanding the Role of the ECU

- What to Look for When Buying a Replacement

- Tips for Maintaining Your Vehicle’s Performance

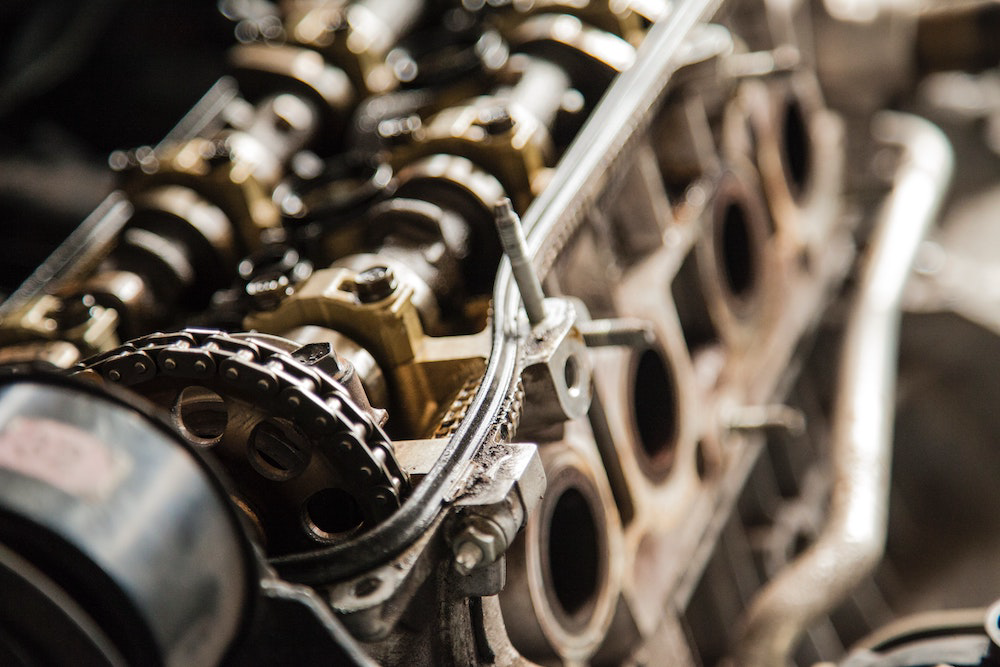

How Camshaft Position Actuators Work

Camshaft position actuators are devices used to control the timing of a vehicle’s camshaft. They are typically found in modern vehicles with internal combustion engines and are responsible for controlling the opening and closing of the engine’s valves. The camshaft position actuator is an important component in ensuring that the engine runs smoothly and efficiently.

- The camshaft position actuator works by using a series of gears, pulleys, and levers to move the camshaft about its crankshaft. This movement is controlled by an electronic signal sent from the vehicle’s computer system.

- The signal tells the actuator when to open or close certain valves at specific times during each cycle of operation. This allows for precise control over how much air and fuel enter into each cylinder, which helps optimize performance and efficiency.

- The camshaft position actuator also helps reduce emissions by allowing for more efficient combustion cycles within each cylinder. Controlling when certain valves open or close, can help ensure that all cylinders fire at their optimal timing, resulting in fewer unburned hydrocarbons being released into the atmosphere as exhaust gases.

- In addition to helping improve performance and reduce emissions, a properly functioning camshaft position actuator can also help extend engine life by reducing wear on other components such as spark plugs or piston rings due to improper valve timing caused by faulty operation of this device.

Overall, a properly functioning camshaft position actuator is essential for ensuring optimal performance from your vehicle’s engine while also helping reduce emissions and extend its life span through improved efficiency. For more insight, check out our guide on the camshaft position sensor and what it does.

Common Problems with Camshaft Position Actuators

The Camshaft Position (CMP) Actuator is an important component of the internal combustion engine. It is responsible for controlling the timing of the intake and exhaust valves, which in turn affects engine performance. Unfortunately, there are several common problems associated with CMP actuators that can lead to poor engine performance or even complete failure.

- One common problem with CMP actuators is oil contamination. If oil gets into the actuator, it can cause it to stick or malfunction. This can result in incorrect valve timing and reduced power output from the engine. To prevent this issue, it’s important to regularly check and replace any worn or damaged seals on the actuator as well as ensure that all connections are properly sealed against oil leaks.

- Another issue that may arise with CMP actuators is wear and tear due to age or excessive use. Over time, parts within the actuator may become worn out or broken due to normal wear and tear, resulting in incorrect valve timing and reduced power output from the engine. To prevent this issue, regular maintenance should be performed on your vehicle’s CMP actuator including checking for signs of wear such as loose bolts or missing parts as well as replacing any worn-out components when necessary.

- Finally, improper installation of a CMP actuator can also lead to problems such as incorrect valve timing and reduced power output from the engine due to misalignment between components within the system. To avoid this issue, always make sure that your vehicle’s CMP Actuator is installed correctly according to manufacturer specifications by a qualified technician using genuine replacement parts whenever possible.

Benefits of Installing a Camshaft Position Actuator

The camshaft position actuator is an important component of any modern engine. It is responsible for controlling the timing of the intake and exhaust valves, which in turn affects engine performance and fuel efficiency.

Installing a camshaft position actuator can provide numerous benefits to your vehicle, including improved power output, increased fuel economy, reduced emissions, and smoother operation.

- Improved Power Output: The camshaft position actuator helps to optimize valve timing by adjusting the opening and closing of the valves at different points in the combustion cycle. This allows for more efficient combustion which results in increased power output from your engine.

- Increased Fuel Economy: By optimizing valve timing with a camshaft position actuator, you can reduce fuel consumption by up to 10%. This means that you will be able to get more miles out of each tank of gas while also reducing emissions from your vehicle.

- Reduced Emissions: The improved combustion efficiency provided by a camshaft position actuator helps reduce harmful emissions from your vehicle’s exhaust system. This not only helps protect the environment but also reduces wear on other components such as spark plugs and catalytic converters due to less buildup of carbon deposits over time.

- Smoother Operation: A properly functioning camshaft position actuator ensures that all cylinders are firing at their optimal rate throughout the entire RPM range resulting in smoother operation overall. This can help improve acceleration as well as reduce vibration during idle or low-speed driving conditions.

Overall, installing a camshaft position actuator can provide numerous benefits for any modern engine including improved power output, increased fuel economy, reduced emissions, and smoother operation. If you are looking for ways to improve performance or increase efficiency from your vehicle then this is an upgrade worth considering.

The Different Types of Camshaft Position Actuators Available

Camshaft position actuators are essential components of modern engines, as they control the timing of the engine’s valves. There are several types of camshaft position actuators available on the market today, each with its unique features and benefits.

- The most common type is a hydraulic camshaft position actuator, which uses oil pressure to move a piston that adjusts the timing of the engine’s valves. This type is reliable and relatively easy to maintain, making it a popular choice for many vehicles.

- Another option is an electric camshaft position actuator, which uses an electric motor to adjust valve timing. This type offers greater precision than hydraulic models and can be used in more complex applications such as variable valve timing systems. However, it requires more maintenance than hydraulic models due to its electronic components.

- A third option is a mechanical camshaft position actuator, which uses gears or cams to adjust valve timing instead of oil pressure or electricity. This type offers greater durability than other types but may require more frequent maintenance due to its mechanical components.

- Finally, there are also pneumatic camshaft position actuators available on the market today that use compressed air instead of oil pressure or electricity to adjust valve timing. These offer greater precision than other types but require specialized equipment for installation and maintenance due to their complexity.

No matter what type you choose for your vehicle’s engine system, you must select one that meets your specific needs and requirements to ensure optimal performance from your vehicle’s engine system over time.

How to Diagnose and Repair a Faulty Camshaft Position Actuator

The camshaft position actuator is an important component of the internal combustion engine. It is responsible for controlling the timing of the intake and exhaust valves, which in turn affects engine performance.

If this component fails, it can cause a variety of issues such as poor fuel economy, rough idle, misfires, and stalling. To diagnose and repair a faulty camshaft position actuator, it is important to understand how it works and what symptoms may indicate a problem.

- The first step in diagnosing a faulty camshaft position actuator is to check for any diagnostic trouble codes (DTCs) that may be stored in the vehicle’s computer system. These codes can provide valuable information about what might be causing the issue. Once any DTCs have been identified, they should be addressed before proceeding with further diagnosis or repairs.

- Next, inspect all wiring harnesses connected to it for signs of damage or corrosion that could be causing an electrical issue. If any problems are found with these components they should be replaced before continuing with further diagnosis or repairs.

- Once all wiring has been inspected and repaired if necessary, use an oscilloscope to check for proper voltage signals being sent from the computer system to the camshaft position actuator when cranking over the engine or when running at idle speed. If there are no voltage signals present then this indicates that there may be an issue with either one of these components or their connections which will need further investigation before proceeding with repairs.

- If all wiring checks out okay then it’s time to inspect the actual camshaft position actuator itself for signs of wear or damage such as broken mounting bolts or loose parts inside its housing which could cause improper operation when cranking over or running at idle speed. If any problems are found here then they should also be addressed before continuing with repairs.

- Finally, if all other steps have been completed without finding any issues, then it’s time to replace the entire unit. This process involves removing the old unit from its mounting location, installing the new unit into place, connecting all necessary wiring harnesses back up, and finally programming the new unit into the vehicle’s computer system so that it can properly control the timing of intake/exhaust valves. After completing these steps your vehicle should now run properly again without experiencing any issues related to the faulty camshaft position actuator.

Advantages of Using an Electronic Camshaft Position Actuator Over Mechanical Ones

An electronic camshaft position actuator is a device that is used to control the timing of an engine’s valves. It is an alternative to the traditional mechanical camshaft position actuator, and it offers several advantages over its mechanical counterpart.

- The primary advantage of using an electronic camshaft position actuator is improved accuracy and precision. Electronic actuators can precisely control valve timing with greater accuracy than mechanical ones, which can lead to improved engine performance and fuel efficiency. Additionally, electronic actuators are more reliable than their mechanical counterparts due to their lack of moving parts, which reduces the risk of failure or malfunction.

- Another benefit of using an electronic camshaft position actuator is that they require less maintenance than mechanical ones. Electronic devices do not need regular lubrication or adjustment like their mechanical counterparts do, so they can be left alone for longer periods without needing servicing or repair work done on them. This makes them ideal for applications where frequent maintenance would be impractical or costly. Not to mention, the replacement cost for a new camshaft.

- Finally, electronic camshaft position actuators are typically easier to install than their mechanical counterparts due to their simpler design and fewer components required for installation. This makes them a great choice for those who want a quick and easy installation process without having to worry about complex wiring or assembly procedures associated with traditional mechanics-based systems.

Overall, there are many advantages associated with using an electronic camshaft position actuator over its traditional counterpart in terms of accuracy, reliability, maintenance requirements, and ease of installation – making it a great choice for those looking for improved performance from their engines without having to invest in complex mechanics-based systems.

Understanding the Role of the ECU in Controlling the Operation of a Camshaft Position Actuator

The Engine Control Unit (ECU) is a critical component in controlling the operation of a camshaft position actuator. The ECU is responsible for monitoring and controlling the engine’s performance, including fuel injection, ignition timing, and valve timing. To ensure optimal engine performance, the ECU must accurately control it.

- The camshaft position actuator is responsible for adjusting the opening and closing of the intake and exhaust valves at specific times during an engine cycle. This allows air to enter or exit from the combustion chamber at precise moments to maximize power output while minimizing emissions. The ECU monitors various sensors (such as the camshaft position sensor bank 1) throughout the engine system to determine when it should adjust valve timing via the camshaft position actuator.

- When an adjustment needs to be made, a signal is sent from the ECU to activate either an electric or hydraulic motor that drives a gear connected to a sprocket on top of each camshaft lobe. This causes one lobe of each pair of cams on each cylinder head bank (intake/exhaust) to rotate slightly relative to its partner lobe which adjusts valve timing accordingly.

- In addition, some modern engines are equipped with variable valve lift systems which allow for further control over how much air enters or exits from each cylinder during different parts of an engine cycle by changing both duration and lift amount simultaneously via two separate cams per cylinder head bank (intake/exhaust). In this case, both sets of cams must be adjusted by their respective motors driven by signals sent from the ECU for optimal performance levels to be achieved.

Overall, it is clear that without accurate control over its operation provided by an Engine Control Unit (ECU), a Camshaft Position Actuator would not be able to provide sufficient adjustments necessary – through the use of camshaft sensors – for optimal engine performance levels while also minimizing emissions output levels as required by modern regulations standards set forth today.

What to Look for When Buying a Replacement or Upgraded Camshaft Position Actuator

When shopping for a replacement or upgraded camshaft position actuator, there are several factors to consider. First, it is important to ensure that the actuator is compatible with your vehicle’s make and model. Additionally, you should check the specifications of the actuator to ensure that it meets your needs.

The material used in the construction of the camshaft position actuator should also be taken into account. Generally speaking, aluminum and steel are considered to be more durable materials than plastic or rubber. It is also important to consider whether or not the actuator has been designed for high-performance applications; if so, then it may require additional modifications to work properly with your vehicle’s engine.

Finally, you should pay attention to any warranties offered by the manufacturer of the camshaft position actuator. This will help protect you from any potential defects or malfunctions that may occur after installation. By considering all these factors when shopping for a replacement or upgraded camshaft position actuator, you can rest assured that you will find one that meets both your needs and budget requirements.

Tips for Maintaining Your Vehicle’s Performance with Regularly Scheduled Maintenance

1. Check it regularly for signs of wear and tear. Look for any loose or broken parts, as well as any oil or fluid leaks.

2. Replace it if it is worn out or damaged beyond repair. Make sure to use a quality replacement part that is designed specifically for your vehicle’s make and model.

3. Change the oil in your engine regularly according to manufacturer recommendations, as this will help keep it functioning properly over time.

4. Inspect all hoses and belts connected to them regularly, looking for signs of wear or damage such as cracks, fraying, or loose connections that could lead to failure of the system over time.

5. Clean off any dirt and debris from around it with compressed air regularly to prevent buildup which can cause problems with its operation over time.

6. Have your vehicle serviced by a qualified mechanic at least once every year to ensure that all components related to it are functioning properly and are free from defects which could lead to costly repairs down the line if left unchecked.