What does the rod bearings replacement cost? Shafts that rotate within the engine and drivetrain are held in place by rod bearings. The importance of the bearings can result in the engine not starting at all if one or more of them fail. But what signs of rod bearing failure are there?

A damaged rod bearing can be identified by various symptoms, including knocking engine sounds, an oil check indicator light, some debris in your engine oil, and more. Since there are many rod bearings in an engine, it might be challenging to identify the damaged or defective ones if you aren’t a professional. To get the defective bearing fixed or replaced, you must act quickly if you see any of these symptoms of a poor rod bearing.

- What is Rod Bearing?

- Causes of Rod Bearing Damage?

- What does it Sound Like?

- Rod Knock Symptoms?

- Engine Knock Causes?

- Rod Knock Fix?

- Rod Knock Repair Cost?

- Replacing Rod Bearings?

Rod Bearing

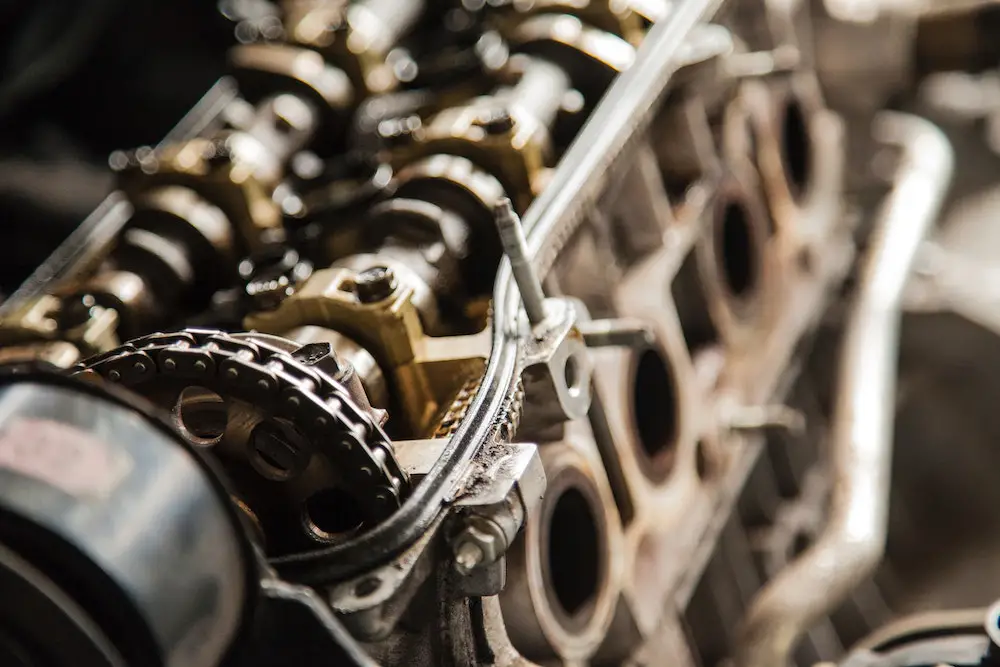

The connecting rod bearing would be a straightforward bearing that rotates the connecting rod as the crankshaft spins using only friction and oil flow, as opposed to a metal ball joint.

A rod bearing holds and supports the rotating shaft where it needs to be sustained. Lubricant can enter the rod bearings’ interior through a hole near the top of the bearings. Additionally, it lessens friction inside the bearing and enables the crankshaft to rotate freely.

The purpose of doing all of that is to ensure that the rods remain upright during the combustion process. The countless parts and elements that make up an engine are just a few. These parts are all kept inside the cylinder of the vehicle’s engine.

It’s crucial to be aware of the common signs of this issue, which include a knocking noise that happens suddenly while driving, rattling noises while the car is moving, and the existence of an illuminated check engine light.

In order to protect pistons from wear from contact with cylinder walls and other surfaces, connecting rod bearings are used. These bearings have the potential to seriously harm your engine if they are not operating properly.

Causes Of Rod Bearing Damage

Rod Bearings Replacement Cost, Failure Causes #1: Debris and Dirt

You can tell if an engine bearing is weak by listening to the sounds it makes when it’s unclean or polluted. Debris like dirt or grime can damage the bearing surface, leaving you wondering what a faulty engine bearing sounds like. Debris may also become embedded in the surface and cause scratches if the lubrication system isn’t working properly.

Rod Bearings Replacement Cost, Failure Causes #2: Not Enough Lubrication

Under lubrication is the second possible cause of engine bearing issues. The bearing will seize if the crankcase is improperly greased, leading to engine failure and, if necessary, a costly repair.

There will be a lot of friction and metal-to-metal contact if there is insufficient oil film.

Rod Bearings Replacement Cost, Failure Causes #3: Poor Engine Bearing Assembly

Misassembly is another factor that can lead to engine bearing failure. If a bearing cover or attachment rod is placed incorrectly and receives insufficient lubrication, bearings may not work properly. In addition, if you don’t have enough lube, a bad engine bearing will sound.

Rod Bearings Replacement Cost, Failure Causes #4: Engine Bearing Crush

The external force produced by the bearing half that passes above the housing bore when the bearing halves are properly aligned is referred to as a crush. This bearing spare material presses the bearing’s outer diameter against the housing’s bore. The engine bearing is kept in position by the bearing crush.

Rod Knock

Rod knock is a tapping sound that originates inside your engine and usually gets louder at higher speeds or during periods of load. There are other things that can generate a rod-knock-like noise, but if you genuinely have rod knock, you need to know what you’re dealing with. Check your manifold gaskets and other potential sources if the knocking noise seems to stop after the engine warms up and isn’t a rod knock.

Rod knock is the noise made when a rod or several rods “knock” against the crank as it rotates in a new direction. A bearing constructed of a softer material than either the rod or the crank is located between the connecting rod and the crank.

When the engine is manufactured, the bearing to the surface of the crank journal has gap tolerances (measured in 0.001-inch increments). Oil can enter and stay on the bearing surface due to this little space. A barrier is created between the two surfaces by the oil film.

Rod knock develops as a result of the oil’s failure to provide a sufficient barrier when the bearing ages and this gap expands. However, premature rod knock is not always the result of normal wear (which might take hundreds of thousands of miles), it can also be brought on by damage to the bearing or crank journal. A few of the culprits that might ruin your day are low oil pressure, unclean oil, and total loss of oil pressure.

Rod Knock Symptoms

There are two typical symptoms if the car actually has a worn-out rod bearing and isn’t knocking for one of the other causes.

1. A Knocking Noise

Obviously, a banging sound is a rod knock’s primary symptom. When you initially start the car, this loud banging is probably what you’ll hear. Additionally, it will rise as you add more load onto your car or depress the accelerator.

2. Reduced Oil Pressure

You can detect lower oil pressure than usual when a bearing has failed or is about to fail. It becomes most obvious when the car initially starts up. Your dash may even display the Check Oil light, alerting you to the pressure. It is a clear sign that a bearing has failed if the light goes off and pressure returns to normal after a few minutes.

Engine Knock Causes

Rod knock is most frequently caused by connection rod bearing wear. Although there is only one cause of rod knock, a number of different factors can result in symptoms that are comparable to rod knock. The following are some of the factors that could result in rod knock or symptoms that are similar to rod knock:

1. Damaged Bearings

Worn bearings are the only factor in the rod knock. The crankshaft, which transmits power to the wheels, rotates as the pistons in your car’s engine rise and fall. The bearings are in charge of maintaining the smooth, controlled movement of the piston. But as time passes, their bearings deteriorate and may lose their position.

When the bearings are worn, the piston rods start rattling against the crankshaft, producing a distinctive knocking noise. Since the bearings are located deep inside the engine, the only method to fix this is to replace them.

2. Fuel/Lean Air Mixture

Lean air/fuel mixture is another factor in detonation knock. Oxygen sensors, fuel injectors, a broken fuel pump, and mass airflow sensors might all be to blame for this issue. When there is too much air and not enough fuel, the result is a lean mixture. Multiple detonations result from the mixture’s inability to burn quickly enough with insufficient fuel.

3. A Bad Knock Detector

A broken knock sensor is another cause of detonation knock. Fortunately, this doesn’t frequently happen because the air/fuel ratio, timing, and fuel injectors are computer-controlled in more recent vehicles.

The knock sensor recognizes any circumstance that might be causing the noise and alerts the ECU to take immediate corrective action. Therefore, if the car’s knock sensor is malfunctioning, the computer won’t know how to fix the problems and may let the engine knock.

4. Lower Octane

A knock from an explosion may resemble one from a rod. The air and fuel combination burns in each cylinder in a single detonation if the engine operates as it should. On the other hand, the detonation knock happens when that mixture explodes multiple times at once, producing a banging sound.

Octane that is too low for the engine is one such reason for this knock. You require a higher octane level than typical cars if you have a performance engine. High octane avoids that knock by burning consistently. Simply using a higher octane fuel will solve this issue next time you fill-up the car.

5. Inadequate Timing

Bad engine timing is another cause of the detonation knock. The timing describes when the spark plugs ignite. The computer is in charge of timing. When the timing is incorrect, the spark won’t ignite when it should, resulting in several cylinder detonations. This brings the detonation knock on. The timing needs to be fixed in order to address this.

6. Defective Belt Tensioners And Pulleys

The last potential cause of an engine knock is something that isn’t even coming from the engine. Similar noises can be produced when the auxiliary belt is not tensioned correctly.

The belt turns when the engine turns. It is attached to multiple pulleys in the engine bay and needs to be pulled precisely to operate smoothly and quietly.

If the belt becomes loose, the tensioner isn’t operating properly. However, if one of the pulleys bends, you can also experience issues. The rattling, slapping, and clicking noises that result from this situation could be misinterpreted as an engine knock. You only need to change the belt, tensioner, or pulley to get this right.

Rod Knock Fix

The only rod knock quick fix is an engine repair in which the rods are removed, and the bearings are changed. The crank has to be polished and most likely twisted because it’s possible that the flailing rod damaged the crank journal surface. To remove any surface dings, they actually spin the crank journal, on which the rod bearing rides, by grinding it down, reducing the journal’s diameter.

It is necessary to run thicker bearings that correspond to how much the crank was rotated after it has been turned and polished. While you’re at it, you might as well swap out the crank main bearings and look for potential causes of the rod bearing failure that you can fix, like a broken oil pump.

Rod Bearings Repair Cost

The rod knock repair cost will be at least $2,500. A connecting rod repair on a select few cars, like a Subaru Forester, may cost $5,000 or more in components and labor. It’s difficult to replace connecting rod bearings.

The problematic component is firstly deep into the engine. You will require new engine gaskets and seals, cylinder head bolts, and connecting rod bearings. The lines for the cooler and engine both need to be flushed.

In some cases, you will also require new timing chains, crankshaft, camshaft, connecting rods, pistons, and piston rings. It might be wiser to think about heavily rebuilding the engine due to the additional parts needed.

How To Replace Rod Bearings

To properly repair it, you must first:

Rod Bearings Replacement Cost, Steps To Replace #1: Remove The Connecting Rods

If the connecting rods are not already detached from the crankshaft and the pistons, take them out. Remember that the bigger end of the rods is fastened to the crack with the aid of additional bolds, which also serve to secure the cap.

While the wrist pin, which is secured to the piston with two circlips, needs to be grabbed onto by the little head. After removing each and every clip, each rod’s wrist pin should easily slip out of its piston. The rod will be released by doing this.

Rod Bearings Replacement Cost, Steps To Replace #2: Take Out The Old Bearings

Grab a hammer and a screwdriver. Next, tap each rod’s edge where it meets the end of the cap. Avoid tapping the bearings from the sides.

Rod Bearings Replacement Cost, Steps To Replace #3: Clean The Area

Following the initial procedures, you must use a lint-free rag to clean the bearing surface. Make sure there is no dirt by thoroughly inspecting the surfaces. This might even shorten the life of the motor and result in bearing problems. Remember to clean the bearings before installing them as well.

Rod Bearings Replacement Cost, Steps To Replace #4: Move The Bearings

One of the bearings should be inserted into the rod’s large end. Put a bearing in the end cap after that. A circle will encircle the crankshaft once everything is securely bolted.

Rod Bearings Replacement Cost, Steps To Replace #5: Consider The Bearing

It is necessary to press out the bearing at the rod’s small end. If you don’t have a press, try to complete the process using a socket. After tapping the bearing out, tap a fresh one.

Rod Bearings Replacement Cost, Steps To Replace #6: Put In The Rods

The rods need to be mounted on the crank, and that’s all. To connect the rods to the crank, use Plastigage. As directed by the manufacturer, tighten the rods. Remove the rod and examine the Plastigage to determine whether the tolerances are in ideal condition.

Thrown Rod In Engine

The metal link between the piston and crankshaft has literally snapped in this severe engine condition. Modern automobile engines have multiple cylinders, which means that the crankshaft is connected to numerous pistons.

Even one piston-crankshaft connecting rod breaking would result in a pronounced knocking noise. In this situation, the car needs to be stopped, then the engine needs to be fixed at a mechanic’s workshop.

When a thrown rod in an engine occurs, two things could happen. As follows:

- When the piston is moving upward in the cylinder and the connecting rod breaks, the piston jams at the cylinder head.

- The worst-case scenario is, however, when the piston drops and the connecting rod breaks. The earlier broken rod may have penetrated the engine block, harming the entire mechanism.

Rod Bearings Replacement Cost

The typical cost of replacing a rod bearing is between $2,000 and $3,000. The “rod bearing replacement cost” now includes components and labor. It includes the necessary replacements, deterioration of the engine bearing, and noise brought on by the problematic engine bearing.

On occasion, the motor may need a new shaft. However, you could also need to restore more components if the loss is more significant. It can be expensive to replace these.

Rod Bearing Maintenance

By following these instructions, you can keep your car’s connecting rod bearings in good condition and prevent costly future repairs. Following these rules will make maintaining your connecting rod bearings relatively simple.

- If necessary, check your fluid levels and top them up.

- All bolts should be tight, and any that are broken should be replaced.

- Before installing each bearing, grease its interior surface.

- To ensure that each bearing’s outer edge may move freely without being obstructed by anything else, ensure there is enough space between it and any other components that may come into touch with it.

FAQs On Rod Bearings Replacement Cost

What Is Rod Knock

When a rod knocks, the engine makes a loud rapping noise. It results from damage or wears to the rod bearing. The car’s connecting rod bearings move more due to their excessive clearance. The banging sound is caused by metal starting to strike as the piston shifts in direction.

How To Fix Engine Knocking

When the air-fuel mixture is off, the engine frequently knocks. An octane booster can be included in the mixture to combat this. In turn, the knocking may stop if the octane rating is correct. In the US, 87 octane is the minimal level that is advised.

What Causes Rod Knock

Rod knocks are typically the result of internal engine components, including connecting rod bearings, wearing out or being damaged. Low engine oil, bad belt tensioners or pulleys, faulty knock sensors, lean air-fuel mixture, improper timing, and low octane are the main causes of rod knock.

What Does A Rod Knock Sound Like

If you’ve heard a rod knock, you can recognize it immediately. When you crank your engine and depress the throttle, you’ll frequently hear loud bangs coming from your engine. Most frequently, you hear it right after you let off the gas.

What Does It Mean When Your Engine Is Knocking

When fuel burns in your engine’s cylinders unevenly, knocking results. Fuel will burn in controlled pockets rather than all at once in cylinders with the right ratio of air to fuel.

What Is A Spun Bearing

The two bearing shells are spinning in place instead of accomplishing their intended duty of holding the rod and end cap together, which indicates that the tiny tabs that are supposed to hold them in place have broken.

How To Diagnose A Rod Knock

A pounding noise is the most typical sign of rod knock. When you turn on your car with a rod knock in place, you will hear a hammering or knocking sound (as if someone is banging metal against your iron door). The noise will get louder as soon as you press the gas pedal.

How Long Can You Drive With Rod Knock

The rod can suddenly shatter once an engine begins to knock. It might continue for six months or until you start it again in your driveway. But eventually, the engine will fail, leaving you stranded.

What Causes An Engine To Throw A Rod

Low oil pressure, excessive engine revving, valve failure, or some loose nuts and bolts are a few causes of an engine reaching the point where it loses a connector rod. Your best line of defense against these problems is proper engine maintenance.

How Much Does It Cost To Replace A Engine

For most autos, replacing an engine costs between $3,000 and $5,000. Unfortunately, it appears that the estimate you received was accurate. It can cost up to $6,000 to replace an extremely sophisticated engine. The average four-cylinder vehicle’s engine replacement costs around $4,000.

Can You Drive A Car With A Knocking Engine

Driving a car with a knocking engine is not advised. If you are not careful, engine knock, also known as ‘detonation,’ can damage your engine’s internal components and cost you more than $3,000 in repairs.

Final Verdict: Rod Bearings Replacement Cost

Preventive maintenance is crucial for the proper operation of a rod bearing. For proper operation, connecting rod bearings must be kept in good condition. Whether you buy a new or used connecting rod bearing for your car, it is essential to know how to maintain one properly. A crucial factor to take into account can be rod bearings replacement cost.

What are the typical signs of rod bearing failure? There are three typical symptoms: a banging noise from the engine, oil debris, and the warning lights. Before any additional damage is done, having the bearings checked as soon as you notice any of these symptoms is critical.