The power of any vehicle largely depends on the powertrain. This part of the cart comprises everything starting from the engine to the suspension and transmission. It’s also responsible for generating your car’s power. A key component of the power train is the often-overlooked flywheel. Between all the glamorous gadgets and fancy components, it’s easy to forget that the flywheel is there. But it’s a super important bit. If you don’t wish to incur high flywheel replacement cost, read this.

A bad flywheel could mess up the performance of any vehicle badly. Find out what a flywheel is, what it does, signs that it’s gone bad, flywheel replacement cost, and much more. Refer to these sections to jump to the part you need to know the best.

- What Is It?

- Functions

- Pros And Cons

- Symptoms

- How Long It Lasts

- Driving With Faulty Flywheel?

- Fixing A Flywheel

- Flywheel Replacement Cost

- Repairing

- Is It Worth It?

What Is A Flywheel?

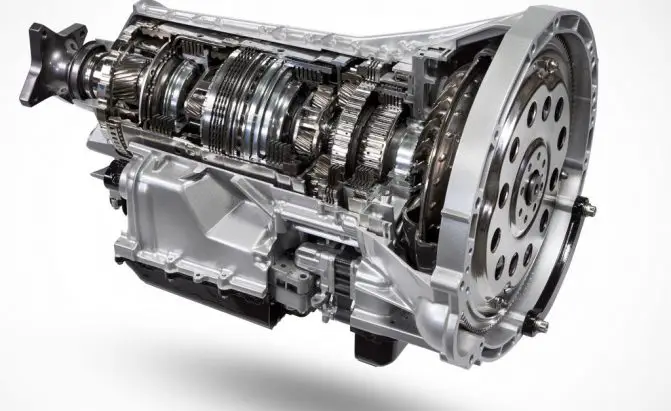

In simple words, a flywheel is a heavy wheel that needs a lot of force to spin on its axis. When the wheel is rotating at high velocity, it will keep moving unless much external force is applied opposite to the motion. When the rotation happens, it saves plenty of kinetic energy which is then consumed by the vehicle to start or accelerate.

A flywheel can be of two kinds depending on whether the transmission is manual or automatic. If it’s manual, it’s called a flywheel whereas an automatic transmission has a “flexplate.” The flywheel is a disc attached to the crankshaft located at the bottom of the engine. It has many different functions.

Flywheel On Manual Transmission Vehicle

On a manual transmission vehicle (and learning how to drive stick), the flywheel acts like one of the friction surfaces. The clutch pressure plate is attached to it while the clutch disk is situated between the two. In contrast, a flex plate on an automatic transmission car can be found bolted to the torque converter.

A toothed ring can also be found along the outer edge and the starter has to turn that to start the engine. Due to the huge disc (in comparison to the crankshaft), the starter motor has added leverage against the car’s engine. It is tasked with a few other engine operations. Bigger flywheels need more energy to spin, but once they start spinning, momentum builds and the engine runs smoother – not to mention the higher RPM.

It’s easy to identify the flywheel in any vehicle. Look for the big, heavy metal disc. It generally sits at the end of the engine and is bolted to the crankshaft, as mentioned earlier. There is a ring gear running around its circumference and its job is to mate with the car’s starter motor once you start the vehicle. In addition, the flywheel is closely linked to the car’s clutch and is in action when a driver is behind the wheels of the vehicle.

Keep in mind that not all cars have flywheels. In fact, cars with automatic transmissions don’t even have flywheels – there’s simply a component that works similar to a flywheel. Even with manual transmission vehicles, some don’t feature flywheels at all. Before you start stressing about the signs of a bad flywheel, make sure your car has it to begin with.

Functions Of A Flywheel

Before we dive deeper into the working principle of this interesting component, it’s best to know what it exactly does. A flywheel is common in almost all kinds of automobiles like buses, trains, and race cars. Flywheels of the past had larger diameters with bulky metal rims and spokes. However, the modern-day flywheel is much more compact since it’s made of carbon fiber or composite material.

To set it in motion, the driver has to push the wheel. In most vehicles, these are the functions a flywheel serves:

Starting Engine

Gear teeth are carved into the circumference of the flywheel, and this helps start the engine. A little gear known as a Bendix gear can be found in the starter motor. It basically connects with the flywheel once the key is turned. The starter/Bendix gear motor combo rotates the flywheel, spinning the crankshaft, and starting the compression cycle needed to start the vehicle’s engine. Once the engine has started, the Bendix gear pulls away, letting the flywheel rotate freely.

Smoothing Engine Speed

After the engine has roared into life, the crankshaft transforms the movements of the pistons (up-and-down) into rotary motion. Regardless, this movement is jerky since power is generated 2 times (for a 4-cylinder) or 4 times (for an eight-cylinder) for every engine revolution.

The flywheel’s mass exerts inertia to maintain speed in the engine crankshaft, making sure it turns between the piston firings.

Balancing Engine

As the pistons fire at all different angles, the engine vibrates with it. The bulky stature of the flywheel keeps this side-to-side movement in check, maintaining balance and stability in the engine while reducing vibration across the vehicle’s body.

Reducing Drivetrain Stress

By smoothing out the engine’s speed and stabilizing its movement, the flywheel reduces strain on other components of the drivetrain. Despite the transmission shafts and the engine being parallel to each other, the joints between the transmission and the axle are not. Universal joints are used on the driveshaft to helps change angles constantly. Flywheels prevent damage to such joints.

Manipulating Weight

The weight is one of the flywheel’s adjustments that engine builders freely customize. They do this to create a part that helps with the performance of a specific engine.

Heavier flywheels let engines function under loads that could result in a bog down of the engine. According to that, cars that are consistently engaged in pulling heavy loads must benefit from a bigger flywheel. A lighter flywheel is better for engines operating at high speeds – such as race cars. Those are better suited for acceleration. But at the same time, it makes keeping the engine idling or accelerating from a complete stop, harder.

Ever wondered why race car drivers need the pit crew to push their car after a pit stop? That’s your answer!

Pros And Cons Of Light Flywheel And Heavy Flywheel

The size and weight of the flywheel change with the kind of torque needed. For a heavy flywheel, more energy has required the change of the rotational speed. Even when you press on the accelerator pedal, the speed of the engine doesn’t increase fast.

All in all, the engine’s responsiveness declines with the engine’s weight increasing. The heavy flywheel supports RPM recovery.

The light flywheel doesn’t deal with as much inertia, so it can respond quickly to deceleration and acceleration. This is why light flywheels are chosen for sports cars. Once the clutch disengages, the RPM drops heavily as there is no heavy flywheel to maintain the momentum. Moreover, light flywheels increase the chances of your car’s engine dying on you during a gear shift.

Symptoms Of A Faulty Flywheel

Sadly, flywheels have an expiration date – similar to all other components of the car. When the flywheel of a car is too damaged or worn out, it will display some signs. Don’t let these signs persist for too long or else you will end up damaging your vehicle. The flywheel replacement cost only goes up with time.

These are some of the most common reasons behind a poor flywheel:

Slipping Gears

If the RPM increases too fast against the ground speed when you shift the vehicle into a new gar, that’s called gear slippage. As the pressure plate and flywheel comes with friction surfaces designed to hold onto the clutch, the car’s slipping flywheel might come off as a slipping clutch.

Let’s assume that grease or oil manages to seep inside the friction surface. It would quickly affect the clutch’s power to engage with and grab the flywheel without slipping, even if the clutch is entirely engaged. If the gear slips when you change it, it goes without saying that it will negatively impact the car’s driving ability.

Inability To Change Gears

This is the exact opposite of the stated first problem. Aside from gear slippage, sometimes the gear won’t change at all. For this symptom to show, the flywheel would have to be in pretty bad condition. Expect to find nearby transmission elements broken too. Since you can’t switch gears, it’s not possible to drive these vehicles.

Burning Odor

Is a burning smell filling the nostrils of you and the other riders in the car? You could attribute this to many causes and a poor flywheel is one of them. If you use the clutch needlessly, this could cause issues with the flywheel.

Clutch Chatter Or Vibration Of The Clutch

If the clutch pedal is put through a ton of vibration, it’s safe to assume that the flywheel is having to tolerate worse. At one point, the vibrations get so bad that they can be felt on the floor instead of simply from the clutch pedal. As you drive your car, excessive runout could damage the flywheel, leaving the surface somewhat warped as the clutch is engaged.

If you’ve ever driven your vehicle for too long with a dying clutch or managed to overheat the flywheel, the flywheel may have been damaged to excessive metal or heat on metal wear. Clutches with wear and tear on the rivets will affect the flywheel.

Since the metal has been heated past the operating temperature, the damaged flywheel might display a bluish hue. There will be some hairline cracks visible on the surface too. Moreover, there could be metal smears on the surface because the flywheel was repeatedly heated and cooled. A few flywheels feature springs, like dual mass flywheels. If a vehicle has one of those, the springs could be the reason behind those vibrations.

Most likely, dual mass flywheels will have to be replaced since they can’t be resurfaced.

Problem In Ignition

There are small teeth on the flywheel that if damaged, can cause trouble starting the motor. Not only does it make engaging the motor harder, but it may become impossible too. It’s worth having a look at the starter if you’re facing issues starting the vehicle. These are some common bad starter symptoms.

Engine Stalling

If you’re replacing the flywheel, it’s important to get the right size and model to suit your vehicle. An aftermarket flywheel, if too light for the car, makes stalling the car easier and can produce a rough idle. On super light flywheels, it is possible to stall the car by doing as much as pushing in the clutch. The engine speed drops a bit too fast and the ECU can’t add extra fuel and air to compensate.

Engine Vibrations With Engaged Clutch

An unbalanced flywheel is more than enough to vibrate the entire powertrain, even if the clutch is engaged. Check the factory service manual. Ensure all the bolts are torqued to the spec if you recently changed the pressure plate, flywheel, and clutch. A loose flywheel or one that disintegrates while you drive is extremely dangerous because the flywheel stores a considerable amount of energy.

The flywheel is a big component and it’s heavy at that, so it can shake the car with ease. If everything isn’t lined up properly and balanced, it’s easy to mess the car up.

How Long Should A Flywheel Last?

So, how long can you go without incurring a flywheel replacement cost? Since the flywheel is responsible for transferring huge loads of power from the engine to the transmission, damage on it could present frustrating problems for you. One of the more hazardous results is the wheels of the vehicle losing power completely. This is why it’s of utmost importance to notice the signs of a bad flywheel and understand when they may strike.

As a general rule of thumb, you shouldn’t have to worry about a flywheel replacement cost for a significant time after first getting the car. The flywheel should serve you for anywhere between 80,000 to 100,000 miles, if not more. But again, as the flywheel is closely linked to the clutch of the car, you might find yourself needing to replace it more frequently to resolve any clutch issues.

Apart from that, you will burn through a regular flywheel much faster if you expose it to constant wear and tear. But that applies to any part of the vehicle.

Is It Okay To Drive A Vehicle With A Faulty Flywheel?

If the damage is in its initial stage, driving around with a faulty flywheel isn’t the worst thing you can do. However, if you suspect that your car has a bad flywheel but you choose to ignore that, just know that you’re playing with fire. The flywheel could still be doing its job perfectly fine when the first signs of damage are exhibited. But before long, you will start seeing more and more of the poor flywheel symptoms popping up.

By primary symptoms, we mean sounds from the flywheel and vibrations that clearly not there before. In a previous section, we mentioned many kinds of signs that tell you your car’s flywheel is dying. But once there’s a burning smell from the clutch, take that as a sign to stop driving the vehicle totally until the repair is done.

In general, a bad flywheel giving off a burning smell will cut off power to the wheel mid-drive. We don’t have to tell you what a dangerous situation that proposes.

Where Should You Get Your Car Fixed For A Poor Flywheel?

A bad flywheel needs to be replaced – a repair won’t cut it. You shouldn’t entrust any random mechanic to fix your car up with the flywheel replacement. It’s best to call for a transmission specialist to get the job done the best. As flywheel replacement is one of the more advanced automobile repair jobs, we suggest going for certified professionals only.

The Replacement Process

Flywheel replacement cost isn’t going to be very light on your wallet, so it’s natural if you want to know more about the replacement process. Some even want to research the process because they plan on DIY-ing the replacement to save money. Whether that is okay will be discussed in the next segment. This is where a specialist will replace the flywheel in your car. Check out this video for a visual guide.

- The car will be hoisted before the wheel hubs and front wheels are removed.

- The oil drain plug is taken out, draining the oil into an oil pan.

- While the draining process is taking place, the lug nuts are loosened. This will allow the mechanic to remove the struts.

- The stabilizer rods are held together by pins on every rod. From the transmission, those will be extracted.

- After that, the mechanic will locate the wires connecting to the engine and battery and remove them.

- Once the bolts are loosened, the transmission can be taken out. The mechanic should be able to find the pressure plate. Once the pressure plate is removed, the flywheel and clutch disc is taken out with it.

- When all the components have been removed, the replacement flywheel will be installed. From there on, the parts will be reassembled following a reverse order.

- The engine oil will have to be refilled before the engine is checked. If any adjustments are required, they are done in this stage.

Depending on the model and make of the vehicle, the average time for flywheel replacement is between five to nine hours.

Flywheel Replacement Cost

The range of a flywheel replacement cost is somewhat large. Some flywheels cost less than $50 while there are versions that cost more than $400. It largely depends on the kind of car you have, how sturdy the flywheel is, and if the part is an aftermarket or OEM replacement. Additionally, the release and/or clutch bearing replacement could be necessary as well.

You have to count the labor costs associated with the replacement job too. As most auto mechanics will ask for about $90 to $120 per hour, the labor cost total could cross the $500 mark. We mentioned how flywheel replacement is a hard task as it’s hard for the mechanic to take the flywheel out and replace it. This takes more time and effort so the pay is high.

On average, flywheel replacement cost is anywhere between $600 to $1,100. You can save yourself a lot of coins if you did the replacement by yourself but only attempt that if you’re an experienced mechanic. If you have a friend or family member who is an expert, you could ask them as well.

Is It Safe To Try To Repair A Poor Flywheel By Yourself?

If you have prior experience fixing up the vehicle, you may be tempted to fix the poor flywheel symptoms by yourself. We don’t recommend that at all – unless you’re a mechanic by profession. The task is complicated and costly in itself, the last thing you need is somehow messing it up and then ending up doubling or tripling the expense.

You may get lucky and be able to take the old flywheel out, but it only gets more complex from there on. The new flywheel needs to be placed in the exact same position and torqued down for best results. A badly positioned flywheel could cause transmission and engine damage and ultimately force you to get pricier repairs done.

Is The Flywheel Replacement Cost Worth It?

Flywheel replacement is definitely not one of the cheapest replacements you will be getting done for your car. You might be asking yourself whether the price is worth it. In our opinion, it all depends. If you plan on driving the car for a few more years at the very least, you don’t have much of a choice. Driving around with a faulty flywheel is simply not an option.

But, if it’s an older car, the fix might not even be worth it. Instead of spending over $1,000 to get that resolved, consider getting rid of your car.

Facts about Flywheel Replacement Cost and Process:

- The flywheel generates and stores energy in a car with a manual transmission to ensure the gears work correctly.

- When the flywheel fails, gears may slip or shift on their own, making driving dangerous.

- Flywheel replacement cost ranges from $400 to $1,300, depending on the mechanic, location, and make/model of the car.

- Labor costs are around $100 an hour, and the replacement process takes about four to nine hours.

- Additional repairs may add to the cost, such as the starter, which can cost $300 to $500.

- The average flywheel replacement takes about five to nine hours to complete.

- Symptoms of a failing flywheel include slipping gears, automatic gear shifts, and burning smells inside the car.

- To replace the flywheel, the mechanic will remove the transmission, clutch disc, and pressure plate.

- After the replacement, the mechanic will refill the engine oil and test the flywheel for any adjustments needed.

- Automatic and manual transmission parts can cost around $50 to $115 on average, but this is for the parts only.

Flywheel Replacement Cost – Conclusion

Flywheel replacement cost may seem like too much but it’s definitely worth it. Although most people are unaware of its existence, the flywheel is a crucial part of the engine. Smooth driving is a great experience, so consider making the investment.

1 comment

I didn’t know that a bad flywheel could mess with the vehicle’s performance. I’ll see what I can do about getting a good one installed. That way my vehicle will run well.