A rod bearing is, to put it simply, a two-piece, smooth metal band that aids in holding an engine’s rotating shafts in place. Sometimes the phrase is used to refer to the connecting rod bearings. If the engine bearings are faulty, what is the cost to replace engine bearings?

You need to know what kind of bearing we are talking about when one claims that worn or damaged rod bearings are the main cause of an issue with your engine.

What is the price of replacing rod bearings? Due to the lengthy procedure, you must take into consideration the cost to replace engine bearings or repair them. For example, determine whether you require new bearings, pistons, camshafts, or timing chains.

It is preferable to replace the whole engine assembly which is when the majority of the components need replacing. When labor and parts are taken into account, the price is typical $2000–3000.

Rod Knock

When you’re driving, you suddenly swear that you could hear an odd sound coming from the engine. There is a deep rapping sound that resembles a small elf tapping something inside using a hammer. The terrible rod knock could it be?

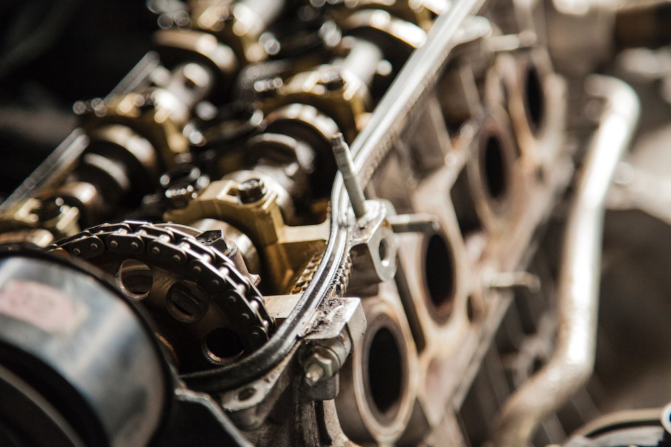

Rod knock is the noise made when a rod or several rods “knock” against the crankshaft as it rotates in a new direction. The connecting rod, or rod for short, connects to the crankshaft, and between them is a bearing that comprises of a material that is softer than the rod or even the crank.

There are spacing tolerances for the bearing to the surface of the crank journal (measured in 0.001-inch increments) when the engine is manufactured. Oil can enter and stay on the bearing surface due to this little space. A barrier is created between the two surfaces by the oil film.

As the bearing ages, this gap grows, and the oil loses its ability to function as an effective barrier, but before you know it, rod knock has developed. However, premature rod knock is not always the result of normal wear which might take thousands of miles it can also be brought on by damage to the bearing and crank journal.

A few of the culprits that might ruin your day are low oil pressure, unclean oil, and loss of oil pressure.

Rod Bearing

The crankshaft and connecting rod are held in position while rotating by an engine rod bearing, which is a split-sleeve type bearing implying it has two distinct ,semicircular halves or shelves.

The crankshaft may spin freely within the bearing without producing too much heat thanks to a pinhole in the top portion of the bearing that keeps that crankshaft lubricated. Your engine contains rod bearings in each piston but also connecting rod assembly.

Main Bearings vs Rod Bearings

Each piston’s connecting rod and its bearings are attached to the crankshaft throws, acting as a crank “handle” to spin the crankshaft as the crankshaft rotates in the main bearings.

However, it might be challenging to distinguish between rod bearings as well as main bearings. This is simply due to the fact that they are both situated close to the engine and crankshaft. The two can be distinguished as follows:

It can be challenging to distinguish between rod bearings as well as main bearings because they are both close to the engine and crankshaft.

1. Location

While main bearings are situated between the crankshaft and the engine block, rod bearings are located between the connecting rods and the crankshaft.

2. Attachment

The larger end of the connecting rod connects to the upper half of a rod bearing, while the lower half connects to the rod bearing cap. The main bearing’s lower half connects to the main bearing cover, while its upper half connects to the engine block.

3. Oil Flow

Before oil gets to the rod bearing, it must travel via the main bearing to lubricate the crankshaft.

Nonferrous metals, or metals without iron, typically make both the rod and the main bearings. Metals that make bearings include bronze and aluminum.

4. Quantity

An engine’s cylinder count determines how many rod bearings it has in total. Usually, the crankshaft of a car contains two primary bearings, one at each end. To enhance engine stability, you can also add more main bearings.

5. Purpose

In order to create a worn surface that you can replace, rod bearings are two-piece shells with a laminate that precisely fits in the big end of each piston’s connecting rod. Rod and main bearings are often absent from lawn mower engines. Every bearing features a tiny tang.

The engine oil pump forces lubrication oil from the crankcase through special holes inside the crankshaft under pressure to prevent the grinding and galling that invariably occurs when lubricating oil pressure is lost from the bearings or crankshaft journals.

Normal wear causes some oil pressure to come down at high temperatures, and when the rod or main bearings start to wear, more oil pressure is lost. Additionally, cam-in-the-block engines feature circular one-piece bearings which can wear or lead to the same issue, whereas overhead camshafts’ cam saddles and caps can wear out and cause reduced oil pressure.

What Leads To Rod Bearing Damage

Rod bearing failure can be a result of a number of factors. Here are a few of the most typical:

1. Not Enough Lubrication

The main factor contributing to rod bearing failure is a lack of lubrication. Everything from low oil levels to a malfunctioning oil pump could be the underlying cause of the problem. Clogged oiling passageways can also cause isolated bearing failures.

2. Misassembly

Premature bearing failure can be due to a variety of assembly problems, including incorrect shim installation, reverse bearing caps as well as halves, and bearing oil hole misalignment.

3. Use Of Subpar Oil

A variety of additives are put in engine oils to prevent bearings from rubbing against one another under high heat and pressure. Using an engine oil that is subpar or that does not meet your vehicle’s requirements could lead to bearing failure since it will not have the proper additives to safeguard your vehicle’s bearings.

4. Additive Fatigue

Overload fatigue, which refers to the development of tiny cracks along the surface of the rod bearing, may be due to excessive load. Once cracks have developed, overlay material can fill them in to reduce load concentration on the bearing.

5. Dirt Buildup

Bearing failure is frequently a result of dirt accumulation. The oil can become clogged with dust, gravel, and metal shavings, harming the bearing lining and thus shortening its lifespan.

6. Corrosion

The buildup of dangerous acids in the crankcase may lead to corrosion in the bearing surface. Although high sulfur fuel content makes corroded bearings more likely in diesel engines, gas cars are also susceptible to this if you do not replace the motor oil on a regular basis.

7. Spun Bearing

Spun bearings are among the worst types of engine failure. It can occur in a race engine, a stock engine, a diesel engine, etc. Because it typically seizes near the crankshaft journal, a spinning bearing is a terrible news.

Depending on where the bearing is, different things will happen. Bearing failures involving spun rods are the most frequent. The rod journal is just on the crankshaft, the larger end bore of the rod, and occasionally the connecting rod is all damaged by a spun rod bearing.

That’s terrible news since, as is clear, a damaged rod rattling about in the engine may cause plenty of damage! The main bore inside the block will damage due to a spun main bearing, although the crank will rarely fail as a result.

Usually, only the primary surface of the journal on the crank as well as the main housing of the bore sustains damage.

8. Different Causes

A series of negative circumstances frequently culminates in a spun bearing. High working loads, extreme heat, as well as a lack of oil are a few of them.

Spun bearings will frequently be attributed to a drop in oil pressure, however, there are many other possible causes that finally lead to the bearing seizing and spinning. The crank can typically move freely on an oil layer that exists between both the surface of the bearing as well as the journal thanks to bearings.

9. The Oil

Everything is good provided there is a constant flow of pure, new oil into the space between both the bearing as well as journal. For continued protection, the film will only need to be thick by only a few microns.

The protective film, however, might vanish in an instant if a sudden reduction of oil flow occurs and pressure particularly at high RPM. Once that takes place, the journal and bearing surfaces come into contact with metal surfaces, which results in more friction, as well as heat.

Any sort of bearing, whether it comprises aluminum or otherwise will begin to melt at about 450 degrees Fahrenheit. A triple metal bearing with a babbitt overlay provides good resistance, but after it wears off, the layer of copper underneath loses that resistance.

As a result, if the absence of lubrication results in enough heat, friction, and scuffing, the bearing melts, spreads, and adheres to the journal of the crank. The result is a spun bearing with the subsequent damage it results in.

Even though this could occur quickly, it’s more common for the bearing to scuff, become hot, and then overheat due to a persistent lubrication issue.

This may cause the crank journal to get brown or the rod’s big end to turn black. Therefore, if you disassemble the engine and view these overheating symptoms, it’s a good indication that the engine does have an oiling problem that requires fixing and repair before putting the engine back together.

Rod Knock Sound

You are impatiently waiting while your automobile is idling and making noise. You have things to do, and the clock is ticking. It sounds as if someone is continuously using a hammer to rap rhythmically on your oil pan. If the engine in your automobile breaks, you may want to sell it online or continue reading to learn more about engine rod knock.

But nobody is under your car, and nobody is banging on the engine. The source of the noise is deep inside your motor. The pitch as well as a frequency change as the engine revs. It appears as if the knocking noise almost stops at one point. The sound carries on and possibly even gets louder as you let off the gas.

This is the sound of a rod knocking. Even while the noise could go down while the engine is cold, it never gets better on its own. Spark knocking, engine knocking, and engine pinging are other names for these automotive engine noises.

Rod Bearing Replacement Cost

The typical price to fix or cost to replace engine bearings and an engine rod bearing that has spun is about $2,000. Parts and labor are part of this. Gaskets, engine lines, cylinder head bolts, crankshafts, and other components will need replacing.

Replacement of a rod bearing often entails:

- Putting the rod bearings together

- Clearing the engine and cooler oils

- Changing the seals and gaskets

Not everyone should change the rod bearing. If you’re unsure of replacing it yourself, you can seek assistance from a reputable service center. Prepare to spend up to $2,000 to $3,000 on that, which covers both labor and the parts needed for the replacement.

It will be better and more cost-effective to merely get a new engine if your mechanic states the engine is faulty as a result of a rod bearing issue and that you’ll need to have connecting rods as well as a new timing chain, pistons, and crankshaft.

However, you only need to replace the faulty rod bearing if your crankshaft or the remainder of your engine is in working well.

Rod Knock Symptoms

Signs of a faulty rod bearing include:

1. Noisy Engine

One indication of a bad rod bearing is noise coming from your engine. Even though most drivers have not seen them, many of them are familiar with these signs.

Rod knock is a sign of piston bearings that need replacing. Engine noises, such as those produced by the valvetrain and the crank’s worn engine bearing, may also be an indication of worn-out engine bearings.

A rod knock is another sign of a damaged piston.

Many engines include an oil main mechanism that initially moves the oil pressure to the crankshaft before moving it to the other sections.

The pressure that the valvetrain needs go down when there are significant oil leaks at the rod and crankshaft. It can result in a light lifter tap that shows the crank’s deteriorated bearings.

2. Decreased Oil Pressure

Typically, a certain air volume will help pump the oil.

The engine will lose oil pressure if there are leaks near the hydraulic filter or engine bearing because the oil will flow through the oil pipes.

Significant bearing wear may result in additional bearing clearance, which can cause oil pressure to drop, especially at low RPM whenever the pump is rotating more slowly.

3. Noise From Transmissions And Worn Belts

There are two different sorts of bearing faces on the bearing.

The first is the crankshaft’s center bearing pad, and the second features the thrust bearing face, which prevents your gearbox from back-and-forth adjusting.

The primary surface of the thrust-bearing face decreases over time.

The crank could accurately move rearward to push the torque converter further into transmission if the thrust bearing is faulty.

Additionally, if the rod journals have enough room to move, they might move very far forward or backward, causing premature wear of the belts prematurely.

This may result in transmission noise and, in some dire circumstances, transmission damage.

Dirt accumulates in your filter as a result of the torque converter’s pressure on the oil pump. The pumps may break as a result of a pressure decrease brought on by this.

Rod Bearing Replacement

The rod bearings are an important component and serve a very distinct purpose. To protect the crankshaft and connecting rods from wear and tear brought on by friction, connecting rod bearings are crucial. The lubricating oil contributes to lowering the heat produced by the metal parts as well as the friction.

The rod bearing deteriorates over time. As a result, you must periodically check to see if they are still valid. If you don’t frequently check your engines, you can experience serious problems.

Follow the instructions below to address and check the issue if you’ve already noticed that the engine has rod-bearing problems.

Cost To Replace Engine Bearings, Replacement Step 1: Get Equipment And Supplies Ready

You’ll need the following supplies and tools to fix these problems:

- Pan seal

- Wrench

- Rain pan

- Fresh motor oil

- The gasket

- Oil pan seal

Cost To Replace Engine Bearings, Replacement Step 2: Buy The Proper Bearing

Disassemble the bad rod bearing from the connecting rod if you can. Send it to an auto store to ensure you obtain the right bearing for the car’s engine.

Cost To Replace Engine Bearings, Replacement Step 3: Label The Components

You must take out the bearing in the crankshaft. You have to lose numerous nuts and bolts in order to remove the defective bearing. Mark the components as you disassemble them to prevent errors when coupling them back.

Place the components in a pristine plastic container. If you want to install a new rod bearing, label them to help you assemble them correctly.

Cost To Replace Engine Bearings, Replacement Step 4: Remove The Old Bearing

It might be difficult to remove. In certain circumstances, you can remove the old bearing without any effort, but in others, you must tap it in order to release the connection. Use a squishy rubber mallet to loosen it. Tap on the top edges only—not the sides—then.

Cost To Replace Engine Bearings, Replacement Step 5: Wash The Components

Clean every component that you removed from your crankshaft. This would aid in preventing the establishment of additional foreign matter that could eventually cause further bearing problems. To clean these components, you could use a degreaser.

Cost To Replace Engine Bearings, Replacement Step 6: Install A New Rod Bearing

As soon as you have cleaned every element, start putting it back together the other way. Add lubricating engine oil to the new rod bearing before installing it.

What To Consider When Replacing Rod Bearings

There are a couple of things that you want to consider when you are shopping for any car component.

When purchasing any auto part, always keep in mind the year, make, and model of your automobile. This will help to make sure the item has the proper specs for simple installation.

Additionally, think about purchasing replacement rod bearings from a company you know and trust. It’s a smart idea to look at aftermarket parts if you’re on a limited budget.

Rod bearings from aftermarket manufacturers (aftermarkets) are constructed using the same premium materials as bearings from original equipment manufacturers (OEMs). These are simpler to get than OEM versions because they are produced by multiple manufacturers.

FAQs On Cost To Replace Engine Bearings

What Is Rod Knock

Rod knocking is a noise made when a rod or several rods knock on the crank as it rotates in a new direction. The rod also called the connecting rod, is attached to the crankshaft, while between them is a bearing constructed of a material that is softer than both the rod and the crank.

What Causes Rod Knock

A deep tapping noise from the engine is referred to as a rod knock. It results from wear or injury. Movement is hampered when a connecting rod’s inside bearings have too much clearance. Metal strikes metal when the piston shifts in direction, creating a knocking sound.

What Is A Rod Bearing

As a split sleeve bearing, an engine rod bearing holds the crank and connecting rod in place while they revolve by having two distinct semicircular halves or shelves.