The GM (General Motors) 4L60E transmission is superbly popular and has many strengths, but it also suffers from countless problems. They include persistent shifting problems and mechanical failures over time, not to mention owners reporting gear slipping, difficulty shifting, or getting stuck in limp mode, often leading to costly repairs.

At a glance, here are some of the most common problems plaguing the GM 4L60E transmission:

- Slipping Transmission – Delayed shifts, high RPMs, a loss of power. This is often caused by low or contaminated transmission fluid.

- Hard Shifting into 2nd Gear – This is typically caused by a faulty TCC regulator valve, leading to rough and abrupt shifts.

- Stuck in Gear (Limp Mode) – The transmission refuses to shift, which is likely due to an electrical fault or sensor failure.

- 3rd-4th Gear Shifting Issues – Worn clutch packs cause harsh or failed shifts between 3rd and 4th gear.

- Won’t Shift Under Acceleration – A failing throttle position sensor (TPS) may prevent the transmission from upshifting.

Trying to fix these problems at home DIY-style isn’t easy, given the complexity of GM’s 4L60E transmission. It was among the first mass-produced gearboxes that introduced electronic shifting, not hydraulics or mechanical controls. With that in mind, further below, we’ll discuss these common 4L60E transmission problems, and what can be done to fix them.

Most Common 4L60E Transmission Problems

Named after its specs and design, the 4/L/60/E is called such as it has… 4 forward gears, a Longitudinal application, 6000 lbs gross vehicle weight capacity, and it features the aforementioned Electronic shifting control. While many argue that the GM’s 4-speed 4L60E is one of the best transmissions ever made, it also has its fair share of drawbacks.

Despite a mostly solid reputation, there are a few things that are well-known to go wrong on a 4L60E. With that in mind, here are some of the most common 4L60E transmission problems:

4L60E Transmission Problems Cheat Sheet

We’ll dive even deeper into each common 4L60E transmission problem with more detail further below, including more detailed insight into its early warning signs, underlying causes, and repair costs. But, for now, here’s a cheat sheet we’ve prepared if you need an even speedier reference:

| Problem | Warning Signs | Symptoms | Possible Cause | Repair Cost Estimate |

|---|---|---|---|---|

| Transmission Slipping | Occasional slipping, mild RPM surges | High RPMs, burning smell, delayed shifts | Low or contaminated fluid, worn clutch packs, torque converter failure | $75 – $3,000 |

| Hard Shifting into 2nd Gear | Slightly firmer shifts before becoming rough | Abrupt, jerky shift into 2nd gear | Worn TCC regulator valve, accumulator piston issues | $200 – $1,500 |

| Stuck in Gear (Limp Mode) | Transmission warning light, occasional stuck shifts | Won’t shift out of first gear | Faulty shift solenoid, wiring issues, sensor failure | $150 – $1,200 |

| Shifting Problems (3rd-4th Gear Failure) | Rough or delayed shifts in 3rd gear before full failure | Won’t shift into 4th, gear slippage in 3rd gear | Worn clutch packs and/or a burned 3-4 clutch assembly | $1,000 – $3,500 |

| Delayed Engagement (Park to Drive/Reverse) | Takes longer than usual to engage gears | Delay when shifting into drive or reverse | Low fluid, internal seal leaks, valve body issues | $150 – $2,500 |

| Harsh Downshifting | Sudden or occasional hard shifts when slowing down | Jerky or clunky downshifts | Bad shift solenoid, transmission control module (TCM) issues | $300 – $1,800 |

| No Reverse Gear | Hesitation or delay when shifting into reverse | Reverse gear won’t engage | Broken reverse input drum and/or a failed sun shell | $900 – $2,500 |

4L60E Transmission Problems (1) – Transmission Slipping

This is by far the most common problem with the 4L60E transmission; gear slippage. If your transmission is slipping, you might notice symptoms such as:

- Unpleasant metallic noises; i.e. whining, grinding, or screeching

- The car is unable to shift properly into some gears, like reverse

- Shifting is inaccurate or delayed; i.e. shifting too early or too late

- A lack of power and acceleration; your car feels sluggish

- Burning or heaty smells

- Check engine light (CEL) turns on

Underlying Causes & Reasons

The most common reason why your gearbox suffers from transmission slippage (including the 4L60E) has something to do with the transmission fluid. It could be that your transmission fluid level is too low (often caused by a leak), or if you’re dealing with old and contaminated fluid. Either way, it can’t properly lubricate and cool your transmission.

Otherwise, if it’s not caused by the transmission fluid, there could be other, prevailing mechanical faults somewhere inside your 4L60E transmission, such as:

- Problems with your torque converter

- Faulty or worn-out clutch

- Bad transmission solenoid (or the solenoid fuse)

- Damaged and worn gears

- Broken transmission bands

Repair Costs

When it comes to the 4L60E transmission, and this applies to most gearboxes with similar issues, the fix could be expensive. It’ll likely need to be rebuilt fully. Or, if individual parts inside the 4L60E could be replaced instead – the worn ones – it could save you a bit there, too. Here’s a rough estimate of how much this might cost:

- Transmission fluid change ($75 to $250)

- Sealing transmission fluid leaks ($100 to $500 – depending on the severity)

- Transmission fluid filter replacement ($100 to $300)

- Gearbox band adjustment or replacement ($200++ – depending on the severity)

- Mechanic diagnostic fees ($100 to $150)

- Full transmission rebuild ($1,500 to $3,000)

4L60E Transmission Problems (2) – Difficulty Shifting From 3rd To 4th

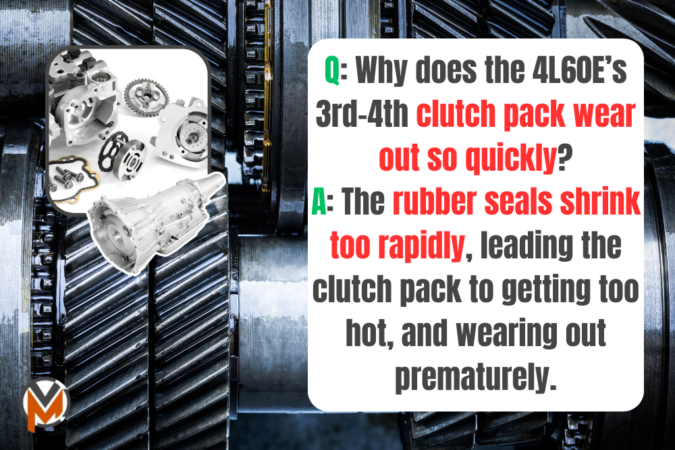

When it comes to the 4L60E transmission and its many problems, the 3rd to 4th gear clutches can wear out quickly. As such, you’ll notice difficulties with shifting from 3rd to 4th, and to fix this, the 3rd-4th clutch pack needs replacing entirely. Or, you’ll need to consider a full transmission rebuild. The underlying cause of this is actually the rubber seals.

The rubber seals on the 3rd-4th pistons shrink rapidly, due to age, heat, as well as general wear and tear. This then leads to the clutch pack getting too hot, and eventually, wearing out very quickly. Some of the symptoms you might experience as a result include:

- Harsh or delayed shifting; mostly from 3rd to 4th

- Slipping between gears; again, mostly from 3rd to 4th

- Burning smells and even smoke, due to the transmission overheating

- Grinding or clunking sounds while shifting

- Transmission warning light illuminating

As mentioned, fixing this often requires a full transmission rebuild, but depending on the severity of the issue, you could get away with just replacing the 3rd-4th clutch pack. Here’s how much this might cost you:

- Transmission fluid change ($75 to $250)

- Mechanic diagnostic fees ($100 to $150)

- Full transmission rebuild ($1,500 to $3,000)

- 3rd-4th clutch pack replacement ($500 to $1,000 – if done separately from the rebuild)

4L60E Transmission Problems (3) – Heavy Shifting Or Can’t Shift Into 2nd

The 4L60E also suffers from issues where you’re unable to shift into 2nd gear, or it shifts heavily. Now, if this is caused by a cracked or fractured drive shell, there’ll be no reverse gear, either. A typical problem with these is that the planetary gears and input ring gear get damaged, and this might’ve even stripped some of its splines. If so, you’ll need a new drive shell.

Common symptoms, aside from not being able to shift into 2nd, include:

- Being stuck in 1st gear, as you can’t shift into 2nd

- Loss of reverse gear, or if it proves unresponsive

- Grinding or clunking noises (mainly while shifting into 2nd)

- Transmission warning light illuminating

As noted earlier, this oftentimes requires a replacement of your 4L60E transmission’s drive shell, so here’s a guesstimate of how much this might cost you to do:

- Transmission fluid change ($75 to $250)

- Mechanic diagnostic fees ($100 to $150)

- Drive shell replacement ($500 to $1,500)

- Full transmission rebuild ($1,500 to $3,000 – only applicable if the drive shell replacement didn’t work)

Hard Shifting Into 2nd

However, aside from not being able to shift into 2nd gear, you might otherwise face issues where your 4L60E shifts hard and rough into 2nd. This is mostly caused by a faulty or worn TCC regulator valve. If you notice a check engine light, it may be accompanied by diagnostic code 1870 (internal slippage). Fixing this often requires replacing the TCC regulator valve.

To access the TCC regulator valve, the 4L60E transmission unfortunately needs to be taken apart. However, replacing the TCC regulator valve should solve that hard shifting from 1st to 2nd. To be more specific, here are some of the more common symptoms you might experience if the TCC regulator valve breaks:

- Abrupt jerking and jolting when shifting from 1st to 2nd

- Check engine light illuminates

- Diagnostic code 1870 is recorded; indicating internal gear slippage

- Unusual and audible clunks or thuds while shifting

The costs that might be involved in fixing this include:

- Transmission fluid change ($75 to $250)

- Mechanic diagnostic fees ($100 to $150)

- TCC regulator valve replacement ($300 to $1,000)

- Full transmission rebuild ($1,500 to $3,000 – only applicable if more issues are found besides the TCC regulator valve)

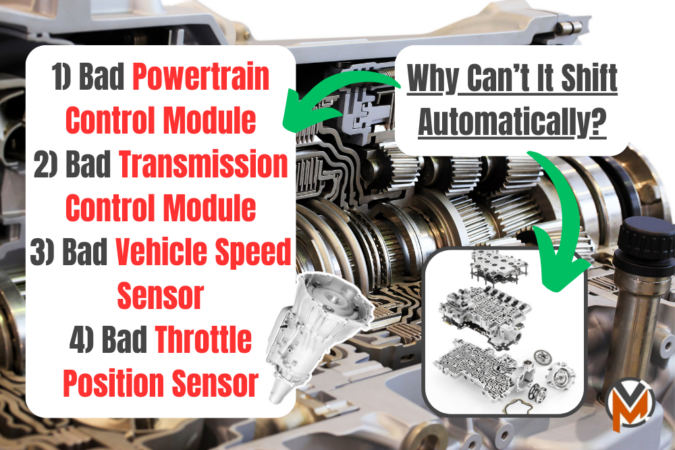

4L60E Transmission Problems (4) – Transmission Only Shifts Manually

The GM 4L60E is an automatic transmission. Therefore, if it requires you to manually shift, there’s likely a fault with the electrics. This means a bad PCM (powertrain control module) or TCM (transmission control module), or one of the sensors sending data to them, like the VSS (vehicle speed sensor) or the TPS (throttle position sensor).

Alternatively, there could also be issues with the wiring, such as a short circuit or a damaged circuit. So, fixing this involves either replacing bad sensors, getting new wiring, or replacing the entire PCM. As such, some of the symptoms you might experience include:

- No automatic shifting, even in ‘Drive’, and requiring you to manually shift

- Transmission or check engine warning lights appearing on the dash

- Inconsistent shift points; it might not shift at the usual or ideal RPMs

- Delayed or hesitant shifting, and sluggish performance overall

The costs to fix this varies depending on what needs to be done, but this should give you a rough idea:

- Sensor replacement, either the VSS or TPS ($50 to $200)

- Wiring repairs ($100 to $500)

- PCM or TCM replacement ($500 to $1,500)

- Mechanic diagnostic fees ($100 to $150)

4L60E Transmission Problems (5) – Won’t Come Out Of Gear

Another one of the common GM 4L60E transmission problems is being stuck in one gear (usually the lowest gear). This is usually due to your GM car being stuck in its ‘limp home’ mode, as the PCM senses a problem, and limits your transmission from shifting. Acceleration will be non-existent and your car will feel very heavy, as other non-essential systems turn off.

If your car does go into ‘limp home’ mode, don’t delay, and visit your local mechanic to get it checked out. Other symptoms you might notice include:

- Your car refuses to shift and remains in only one gear (usually the lowest)

- Struggling to pick up speed and accelerate

- Increased engine vibrations; similar to a transmission shudder

- Deactivating non-essential systems, like the air-conditioning turning off

- Check engine light flashing or remains lit up

The costs that might be involved in getting this fixed include:

- OBD scan ($5o to $120 – some shops offer this for free)

- Mechanic diagnostic fees ($100 to $150)

- Sensor replacement ($50 to $300 – depending on what sensor it is)

- Transmission repairs ($500++ – depending on the repairs and severity)

Won’t Shift Under Acceleration

On the other hand, if your transmission won’t upshift while under acceleration (often from 1st to 2nd), it could be a problem with the throttle position sensor (TPS). Some of the additional symptoms you could notice if this was the case might be:

- Unable to shift from 1st to 2nd, unless you release the throttle

- Erratic transmission behavior, like sudden jerks or odd sounds

- Check engine light turns on

- Decreased acceleration or lack of responsiveness

Aside from the usual mechanic diagnostic fees, a brand-new TPS can cost you upward of $300. Additionally, you’ll need to consider general transmission repairs, if the issues are elsewhere. This may cost you at least $200 or more, depending on how severe the problems are.

My Chevy Astro, lost all forward motion suddenly whilst driving it, although reverse still worked, there was no sound of anything breaking that I could detect, could this be a transmission failure or simply an electrical problem.

Thanks

Thanks for the comment, Derek Shanks!

Ooof, that sounds scary, but it’s good to hear that you’re all good. It’s most likely a mechanical failure in this case, although electrical/electronic issues (solenoids, etc.) could also be the culprit. It’s hard to tell, but hopefully, you’ve had it sorted out.

Great writeup! The 4l60e can be a good transmission when properly taken care of, but certainly has its fair share of issues.

Thanks for the comment, Jimmy Lucas!

Yeah, it’s a pretty solid transmission and a great pairing for an LS swap project. But as you say, it requires diligent care and attention to have it serviced regularly to ensure that problems don’t crop up suddenly.

Does anyone have any ideas why after changing my oil filter dip tube O ring (which requires pulling the transfer case) in my 2011 Chevrolet silverado 1500 4×4 5.3 the truck will Not let me shift into drive…it shifts into P N R and will drive in Reverse but physically can’t shift into D.

Thanks for the comment, Trevor!

This is an interesting problem, for sure. There might have been some issues with the low range box, which is the most likely cause, from what I can tell. Otherwise, it’s also possible that the shift solenoid has been stuck open during the operation, or that the speed sensor has gone bad. Hope that helps.

I have Cadillac escalade suv 2005 and the transmission in 4l60e.

the gear 4 not work .

please help me

Thanks for the comment, fouad abusetta!

From what I’ve learned, a failure to shift into 4th gear on a 4L60E is likely attributed to a bad shift solenoid. Otherwise, one of the transmission bands is badly worn out, or perhaps the servo piston for the 4th gear has malfunctioned. Alternatively, it’s also possible that the valve body isn’t working right. If you’re keen to diagnose either one, it’s best to start with the solenoid, then the servo, and move on from there.

hi my son has a 2004 gmc Searia, 4L60E i replaced the solenoids and used a scanner to clear it but it still has a issue shifting into 3rd gear. where are the fuses located at that make the solenoids work.. it was his dads truck he really wants to fix it because his dad passed away last year.. please help

Thanks for the comment, kristie!

If replacing the solenoids didn’t work and neither would an OBD scanner clear it, checking the fuses is a great idea. The fusebox for most GMC models should be located under the hood, on the driver’s side. They’re pretty easy to find, and there should be a diagram or schematic of some kind on the fuse box panel. That should tell you where the transmission solenoid fuses are. In particular, try to find a fuse marked as TCMB, which is made for the Transmission Control Module. You can refer to this site to learn more about a 4L60E fuse: https://www.700r4transmissionhq.com/4l60e-fuse-location/

Had reman trans installed 6 months ago pulld in my drive went to back up no reverse then no drive as well it was out of fluid now it wi shift if I shift it but revs up in hi gears could vss be issue 97 4×4 5.7

Thanks for the comment, Steven!

For a case like this, it’s a good idea to check and make sure that the transmission fluid is all in order – in good condition, at adequate levels, etc. Once that’s done, diagnosing the VSS or shift solenoid is a decent place to start next if this problem wasn’t already solved.

I purchased a gm 4L60E trans for my hot rod, was told it had 20k on it and it looks like it. It also had a fairly new torque converter. Bought the TCI kit to run it in my 33. Problem being, installed everything got everything hooked up ready for road test and No Go. Every gear is like being in park, engine just revs. Fluid looks correct, un hooked one of the hoses to the trans cooler and no fluid comes out when engine is started. Could the converter of come disigaged when bolted up to flywheel ? 🤔. Help

Thanks for the message. This is a tricky one to comment on being a custom install. I really don’t think I can add much info. Having installed it you would know a lot more about it than me. I would do what you can to make sure all the fluid is correct and consider if there could be a blockage.

But you might have to speak with a local mechanic that can take a look. Sorry I cant be more helpful.

Same issue when replaced my transmission in my Chevy trailblazer. No go at all. Just revs.. but my gearshift is stuck also. Cables are fine, fluid fine.. no visible reason for the issue..

Have a 1999 chev astro van, all of a sudden it wouldn’t shift outa 2nd gear. then if it sat for a bit it would shift fine,Untill it didn’t most likely in the same trip. only just turned 100,000 Miles and gingerly miles

hey everyone, I need some help here I have 93 one-piece case 4l60e trans tag number (3KCD336B) and I’ve been following this guy’s videos wall I’ve been rebuilding mine and for some reason I cannot get the clearance needed for the 3-4 clutch pack I’m only getting 0.20″ and even doing the math to change the steels and or the backing plate is not coming up close enough to what it needs to be. anyone got any ideas of what I can try

2004 Cadillac escalade AWD lost all 3-4gers.help

Marjorie, I’m sorry to hear about the transmission issues you’re facing with your 2004 Cadillac Escalade AWD. Losing all gears between 3rd and 4th can be a significant problem. Based on the previous conversation about common issues with the 4L60E transmission, it’s possible that your Escalade might be experiencing a failure in the 3-4 clutch pack or a faulty shift solenoid.

It’s important to have a qualified mechanic or transmission specialist diagnose the problem accurately. They will be able to provide you with a more precise assessment and recommend the necessary repairs or replacements. It’s worth noting that transmission problems can vary, and it’s always best to seek professional advice rather than trying to fix it yourself.

I hope this information helps, and I wish you the best of luck in resolving the transmission issue with your Cadillac Escalade.

My transmission won’t shift 1-2nd without letting off the gas and once in higher gear if you accelerate to fast will down shift into first gear

Can i use the L460E in my 1999 ls 2×2, in my 1999 ls 4×4? By swaping parts?

The 4L60E transmission is commonly found in various GM vehicles, including the 1999 LS models. However, there are some differences between the 2×2 and 4×4 configurations that need to be considered before swapping parts. The main distinction lies in the transfer case and output shaft.

In a 4×4 vehicle, the transmission is designed to work in conjunction with a transfer case, which distributes power to the front and rear wheels. The transfer case is not present in a 2×2 vehicle. Therefore, if you want to use a 4L60E transmission from a 2×2 LS in your 4×4 LS, you will need to ensure that the transfer case and output shaft from the original 4×4 transmission are compatible with the 2×2 transmission.

It is important to note that the specific configurations and compatibility may vary depending on the make, model, and year of your vehicle. Therefore, it is recommended to consult a mechanic or do thorough research to ensure that all the necessary parts are compatible before proceeding with the swap.

Can I use my 1999ls 2.2trans in my 1999 4x4ls 4.3

In response to Chris’s question about using a 1999 LS 2.2 transmission in a 1999 LS 4×4 4.3, it is important to note that the compatibility of these transmissions depends on several factors. While both vehicles are from the same year and model, the differences in engine size and drivetrain may affect the compatibility of the transmissions.

It is recommended to consult with a qualified mechanic or transmission specialist to determine if the 1999 LS 2.2 transmission can be used in the 1999 LS 4×4 4.3. They will have the expertise and knowledge to assess any potential compatibility issues and guide you towards the most appropriate solution.

Additionally, it’s worth mentioning that even if the transmissions are compatible, there could still be other factors to consider such as modifications, wiring harnesses, and mounting points. Therefore, seeking professional advice is crucial in order to ensure a successful transmission swap without any unforeseen complications.

I have a 93 Chevy 3500 with 4L60E transmission that blows the transmission fuse. It works fine untill the fuse blows. Is there any internal wiring that would blow the fuse?

Hi LeRoy,

When a vehicle’s transmission fuse keeps blowing, it typically indicates an electrical problem in the transmission system. In the case of your 1993 Chevy 3500 with a 4L60E transmission, there are several potential causes for the fuse blowing, and it’s essential to diagnose the issue properly to determine the exact source of the problem. Here are some possible reasons:

1. Short Circuit: A short circuit in the wiring or a component within the transmission system can cause excessive current flow, leading to the fuse blowing. Check the wiring harness and connectors for any signs of damage, exposed wires, or loose connections.

2. Faulty Solenoids: The 4L60E transmission uses solenoids to control various functions. A malfunctioning solenoid can draw too much current and blow the fuse. Inspect and test the transmission solenoids for proper operation.

3. Faulty Sensors: Sensors such as the vehicle speed sensor (VSS) or transmission input/output sensors can also cause electrical issues. A malfunctioning sensor can lead to a short circuit or excessive current draw.

4. Internal Transmission Wiring: While less common, internal wiring within the transmission can be damaged or worn over time, causing shorts or other electrical problems. This might require a transmission rebuild or repair.

5. Grounding Issues: Poor or corroded ground connections in the transmission system can lead to electrical problems, including fuse blowing. Ensure that all ground connections are clean and secure.

6. Aftermarket Modifications: If any aftermarket electrical components or modifications have been added to the vehicle, they could be the source of the problem if not installed correctly.

To diagnose and repair this issue, you may need the assistance of a qualified mechanic or automotive electrical specialist. They can perform electrical tests, inspect the wiring, and use diagnostic tools to pinpoint the exact cause of the fuse blowing. It’s essential to address this issue promptly, as driving with a repeatedly blown transmission fuse can lead to transmission damage and other issues.

Hey Gentlemen. My son and myself just rebuilt a 4L60E in a 2004 Chevy Trailblazer. After it was installed and driven for about 50 miles it shifted into Overdrive and now seem to not want to come out of it. Any idea on a possible fix ?

It seems like your 4L60E transmission is stuck in Overdrive, which may be causing the vehicle to remain in a higher gear even at low speeds. Here are some steps you can take to diagnose and potentially fix this issue:

Check the Transmission Fluid: Ensure that the transmission fluid level is adequate. Low fluid can lead to shifting issues. It’s also essential to verify the fluid’s condition; burnt or discolored fluid may indicate internal issues requiring further attention.

Inspect the Transmission Linkage: Make sure the shift linkage is functioning correctly and isn’t misaligned or damaged. A misaligned linkage can lead to shifting problems and may prevent the transmission from downshifting correctly.

Examine the Solenoids: The 4L60E transmission uses shift solenoids to control gear changes. If one or more solenoids are faulty, it may prevent the transmission from shifting out of Overdrive. Consider checking or replacing these solenoids if necessary.

Check for Fault Codes: Use an OBD-II scanner to scan for any error codes related to the transmission. Fault codes can provide clues to what might be causing the issue, such as sensor failures or electronic control unit (ECU) problems.

Transmission Control Module (TCM): If the TCM is malfunctioning, it can lead to erratic shifting behavior. This module controls the shift points and timing, and if it fails, the transmission may not function properly.

If these steps don’t resolve the issue, it may be necessary to consult a professional mechanic for a comprehensive diagnostic. If you need more assistance or guidance, feel free to reach out. Safe driving, and best of luck with the transmission!

this did not touch the question I had about the 2008 GMC SL4d Serria 2Wd 4.8 engine problem i ask about My Transmission has been rebuilt with latest rebuilt valve body wit all new shifter solenoids and It has about 80 thousand miles with good shifting and still shifts fairly well but it has a thump in stop and go traffic it is not constant but at times after stopping in stop and go traffic i get this Thump upon moving after stoping ONE thump as you pull off shifts well and does well tillthe nest stop and go and that thump your artical did not cover anything like this problem

My

gmc

sierra 4Dr 2We

Hi Jack,

The thump you’re experiencing in your 2008 GMC Sierra when resuming movement in stop-and-go traffic could be caused by several factors. Here are a few possibilities:

Engine or Transmission Mounts: One common cause of a thumping or jolting sensation is worn engine or transmission mounts. These mounts secure the engine and transmission to the truck’s frame, and if they are damaged or worn out, they can cause a noticeable thump as they fail to properly dampen the movement of the engine and transmission during acceleration.

Driveline Components: The issue might be related to the driveline, which includes components such as the driveshaft, U-joints, or differential. If there is excessive play or damage in any of these parts, it could lead to a thump as torque is applied when you start moving. Checking for any play or unusual movement in these components can help identify if this is the source.

Transmission Issues: Even though the transmission has been rebuilt, issues can still arise, especially with hydraulic and mechanical components like the torque converter. A malfunctioning torque converter can cause a thump as it engages, particularly if the lockup is not smooth.

Suspension Components: Check the suspension components as well. Worn struts, shock absorbers, or other suspension parts can contribute to a thumping noise when the vehicle transitions from a stop to start, especially under the stress of stop-and-go traffic.

To diagnose this issue accurately, it would be advisable to have a mechanic perform a detailed inspection of the mounts, driveline, and possibly re-evaluate the transmission, especially focusing on the torque converter and any related hydraulic controls. This will help in pinpointing the exact source of the thump and addressing it effectively.