Engine troubles can be annoying to deal with, particularly if you’ve just been informed that you are dealing with a blown engine. This can mean a lot of different problems but typically signifies a significant failure within the engine that will need some level of rebuilding or a full-on replacement.

The reason can be a blown head gasket or a blown bottom end, which are the two most common problems when referring to an engine that’s blown.

- About

- Causes

- Symptoms

- Types

- Diagnose

- Fix A Blown Engine

- Rebuilding & Replacement Cost

- Tips and Tricks

What Is A Blown Engine?

Before everything, let’s understand what we mean by a blown engine, and it has to start with a blown bottom end. This happens if there is a failure in the rotating assembly due to very high RPM, and broken parts from the assembly damage the engine block. In case of extensive damage, the engine block usually cannot be repaired and has to be replaced.

Another problem with engines often associated with a blown engine is a timing chain break or timing belt snap. It can cause significant damage to the engine’s pistons and valves when this occurs. As a result, piston parts can get into the oil pan and cause damage to the internal engine components. This is when professionals recommend replacements, as repairs can be very extensive.

This is why you must get the timing chain or timing belt of your vehicle replaced according to the manufacturer’s recommendations.

A blown gasket head is another severe engine issue. A head gasket can fail in many different ways. Its primary job is to help regulate combustion pressure and stop the coolant and oil from mixing. In the event of a blown gasket head, the oil and coolant can start to leak and/or mix, leading to combustion problems and engine overheating.

The head gasket can be changed, but you have to get the engine checked to understand how much damage has been caused. In addition, other repairs may have to be performed to restore the head gasket to its original condition.

These are only some of the primary issues a blown engine can indicate. However, in a broader sense, the term represents a failing engine. If you have a blown engine at your hands, whether or not it can be repaired is determined by damage extensiveness.

If the damage is somewhat minimal, you can get by with some replacements and repairs. But if the damage is tremendous and cannot be repaired, a complete engine replacement might be in order.

Causes Of A Blown Engine

In the majority of cases, a blown engine is caused by any of these three events:

- Low engine oil: A considerable oil leak that remains undetected slowly empties the oil crankcase. The moving parts of the engine are starved of grease.

- Lack of maintenance: If you don’t change the engine filter and oil regularly, sludge accumulation in the oil galleries will hinder lubrication.

- Over-revving: When you bring the engine’s RPMs beyond its normal operating range, the momentum can cause fan-moving bits to knock out of their usual break and course.

Symptoms Of A Blown Engine

The signs of a blown engine tend to vary with the causes. Keep in mind that just because your vehicle is displaying one or more of these symptoms doesn’t automatically mean that the engine is blown up. Similar conditions can cause these symptoms.

Blown Engine: Blue Exhaust Smoke

If there is blue smoke coming from your vehicle’s tailpipe (or if you notice blue smoke from exhaust on startup), that can be a sign of a blown-up engine. This sign tells you that raw engine oil is entering the combustion chamber.

Blown Engine: White Exhaust

White clouds emitting from the exhaust pipe indicate water or engine coolant dumping into the combustion chamber. Unlike regular exhaust, this exhaust fume is thick.

Blown Engine: Knocking Or Rattling Of Engine

A solid sign something is very wrong in your vehicle is when it starts making noise from the inside. Commonly caused by broken parts or worn bearings, these problems render an engine useless.

Blown Engine: Coolant Mixed In Engine Oil

The cooling systems and engine oil are separated and sealed inside the engine. If you find engine oil in the coolant or vice versa, know a severe problem brewing under the hood; perhaps a blown engine.

Blown Engine: Engine Won’t Start

An engine might not start due to a plethora of things, so you cannot rule out the chances of a blown engine. It can be anything from overheating to improper timing to physical defects in a machine.

Types Of Blown Engines

What are the reasons behind a blown engine? As the term isn’t completely explicit about the specific fault, multiple failures can be connected to a blown engine. These are some of the more common ones:

1. Blown Piston

Piston problems are a common reason behind a blown engine. Interestingly enough, the piston rings are more prone to failure than the piston itself. These metal rings secure the piston against the wall of the cylinder and keep the engine oil inside the crankcase, away from the combustion chamber. Moreover, they keep the combustion contained in the cylinder.

A blown piston could also mean a cracked or partially melted piston. Regardless of the reason, low compression is created in the cylinder.

2. Hole In Engine Block

A hole in the engine block warrants fear. It’s an obvious indicator of damaging impact, whether outside or inside. This is common in high-performance engines if something breaks inside the crankcase, like a connecting rod, and the result pushes the rod.

3. Blown Rod

A rod thrown by an engine rarely breaks the block. Although, it does cause internal damages. A “blown” or broken rod can result from high resistance or an over-revving engine. Occasionally, the wrist pin connecting the piston and connecting rod falls out or breaks, and the rod moves around inside the machine, harming everything it comes in contact with.

4. Seized Engine

The first factor to consider with a seized engine is the lack of lubrication. But, that’s not always the only cause. Oil starvation on moving metal surfaces and bearings generates overwhelming heat and friction, essentially welding the inner parts together. As the engine cannot rotate, it seizes.

5. Broken Timing Chain Or Belt

A steel chain or rubber belt ties the crankshaft to the camshaft. Its job is to maintain engine timing. If the timing chain or belt breaks, valves inside the cylinder head flop around. In some engines, a timing belt break when the engine is running can make the valves negatively impact the pistons.

How To Diagnose A Blown Engine

To know for sure that an engine is blown, you need expert advice. Unless you can pinpoint a hole in the engine block, there is no way to be certain of the engine’s condition without disassembling the bits and diagnosing everything separately.

A mechanic will have to check numerous things like the engine compression in every cylinder, signs of a misfire, leak inspection, and read diagnostic codes (if any) stored in the ECM. Draining the engine oil or pulling the engine oil dipstick for inspection can be good reads (once you’ve figured out how to read oil level on dipstick).

Step 1

Check for big puddles of antifreeze or oil under the engine. Look for obvious damage symptoms like a large crack, a hole in the oil pan from the crankshaft or a rod, or a connecting rod sticking out of the block.

Step 2

Pull the dipstick and check for antifreeze or water in the oil. On a cold engine, remove the radiator cap and inspect for the opposite – a layer of oil floating on top of the antifreeze. While either can suggest a failed head gasket, it could also mean there’s a gaping hole in the block between the water jacket and the oil galleys. There might be a hole in the cylinder wall too.

Step 3

Use the starter to turn the engine over. If the engine refuses to crank, use a socket wrench on an engine pulley to turn it over by hand. Notice if you can hear any unnatural noises in the process. Suspect broken pistons, rods, or other serious problems if there are metallic, grinding noises as it turns.

Step 4

Take out all the spark plugs that can still be turned over, particularly if it turns over too fast. Examine the compression. Many experts believe that an extremely low compression in all or some of the cylinders can be directly linked to a blown engine. Get a shop to do a leak-down test to understand how bad the damage is full.

Step 5

If your vehicle’s engine can still run but knocks or belches blue exhaust smoke, connect an oil pressure tester to it. Suspect worn and main rod bearings if the pressure is below average.

Make sure to calculate the total price of repairing the blown engine before confirming the repairs. It’s time to be brutally honest with yourself about the extent of the damages. One thing can lead to another when rebuilding or replacing major engine parts. Get a good estimate of the total bill before starting.

What Happens When My Engine Fails?

The last thing you want when driving is an engine failure. If this happens, the car can lose power and even run out of gas. What do you do when the engine dies mid-drive?

Start by keeping your eyes on the road as you scan the perimeter for a safe place to pull over. The car may start losing the brakes and power steering, which is alarming. However, we believe you should still guide your vehicle to the side of the road and stop it. Get your phone and contact road service as soon as possible, along with a trusted friend.

Please keep away from your vehicle while it’s hot. Wait for a while for road service to reach.

How To Fix A Blown Engine

So, let’s assume that you have established that your car’s engine is truly blown. Your next impulse would be wondering if it can be fixed, and if so, how. A good repair session always starts with the proper diagnosis. You have to know exactly what is going on with your car.

Firstly, refrain from going on a shopping spree and buying a lot of engine components with proper knowledge. Consider disassembling the engine so you can find the root of the problem easily. This might not always be needed, but we recommend treating it delicately.

Understand What Has To Be Repaired

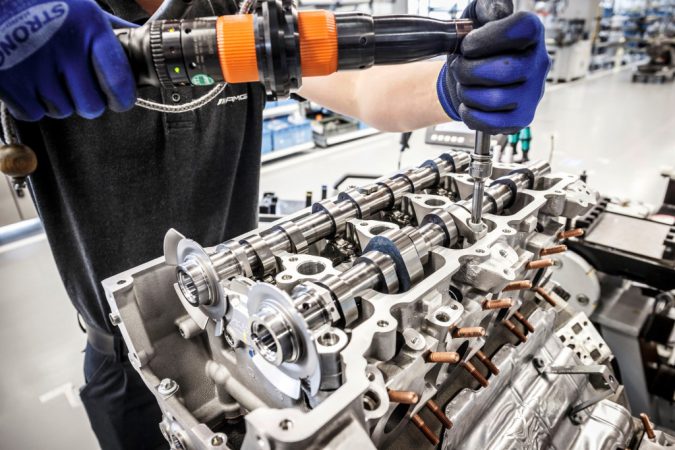

Try to inspect the whole engine during the teardown phase. Go slowly and be organized. Take off the intake manifold and valve covers, checking for dirt in the oil as well as the broken valve train/valve spring components.

Then, remove the cylinder heads and check the combustion chamber roof and piston tops for signs of water leakage, oil leakage, and melted components to ensure nothing leaks.

1. Check The Engine Thoroughly

Inspect the engine carefully for cracks. This means looking in the heads, piston tops, combustion chamber, cylinder bores, deck surface, and engine block deck surface. There is no need to spend a lot of time here; try to be sure. Just because your untrained eye cannot catch anything doesn’t mean the engine is okay.

Seemingly invisible cracks may only be visible by a professional, so we highly recommend going to an auto repair shop, especially if overheating was a primary cause of the engine’s situation.

2. Removals

Remove the pistons, rods, and crankshafts from the engine. While you’re at this, closely observe the bearing surfaces. See if there are any visible signs of gouging.

3. Send Block To Automobile Shop If Required

Depending on the condition inside, you may have to send the block to the automobile shop to have the bearing bores, engine block, crankshaft, cylinder, and cylinder head deck surfaces conditioned to factory specs. This is the time to order whatever parts you need, including rings, bearing, and oversized pistons.

4. Install The Piston Rings

Set the new piston rings in place. Install the crankshaft bearings followed by the crankshaft, rod bearings, and then finally the connecting rods and pistons. Pack petroleum jelly in the oil pump and then install it.

5. Fill The Engine

Filling the engine is a crucial part of the process. You must insert new head gaskets before bolting the heads against the block. Position the new camshaft lifter. Install the camshaft onto the cylinder heads or into the league and install the valve train on the heads segment.

Now, install the intake manifold, intake manifold gasket, exhaust manifold, exhaust manifold gasket, valve cover, and valve cover gaskets and ensure everything is in its rightful place, making the engine strong.

Finally, fill the engine with oil and use a priming shaft and drill to prime the oil pump. The oil pump drive shaft can be accessed through the distributor hole for some engines. If possible, get an assistant for this step who will help you by turning the crankshaft using a wrench.

The oil should now be coursing through the valve train. The engine is ready to install at this stage. Once installed, start the engine and lightly ensure that it works completely before revving it up. You’re all done!

Rebuilding & Replacement Cost Of A Blown Engine

Rebuilding an engine is hard work as it requires a lot of precision work, time, effort, and expensive parts. Thus, the process is pricey too. Generally, rebuilding an engine will set you back several thousand dollars – no chump changes here. You might better purchase a crater engine from a good engine re-builder. Alternatively, if the vehicle is not worth a brand-new engine, you can buy a used one from a junkyard.

It all depends on the engine and the part that’s blown. We suggest replacing the engine, which can cost between $1,000 to $20,000 – depending on the type of the engine. A typical engine rebuild costs around $2,500 to $4,000 in labor costs and parts. This engine repair may only include replacing seals and bearings and taking the engine out to reinstall it later.

The final amount can be much higher too. The cylinder head cannot be rebuilt if the crankshaft is destroyed, the pistons have to be replaced, or if the damages on the engine block are too bad. Sometimes, rebuilding the engine simply isn’t worth it, such as when it seizes. When your vehicle breaks down, you have to replace the engine.

Car Engine Maintenance: Tips And Tricks

A car is a powerful body of complex mechanisms working together in cohesion. Cars have been developed for over a century now, but that does not mean that they are free from error and will work smoothly for your whole life.

The most complex component in a car is its engine. All the components inside have to be working properly at all times to make sure you get the most out of your vehicle. Fortunately, engine failures aren’t a condition that most drivers are likely to face now and then. But that also doesn’t mean you can forget about it.

Keeping the engine healthy can safeguard your car from various (expensive) problems.

1. Change The Filters Regularly

The oil and air filters in your vehicle count as the first line of defense. These components help keep debris out of the internal parts and maintain the cleanliness of the oil lubricating the engine. These make sure the combustion process runs optimally without any unnecessary wear and tear.

You must change these filters at prescribed intervals.

2. Top-Up Engine Fluids Regularly

Your car’s engine oil and coolant levels must always be at the correct level. This can be done easily with the guide marking and dipstick in their respective compartments. Engine oil keeps all core engine components greased and functioning properly at all times. Low engine oil levels can result in more wear and tear.

The coolant effectively disburses the heat created by the engine. Low coolant levels may also cause the engine to overheat, damaging the internal components.

3. Change Spark Plugs And Timing Belts

A timing belt ensures the engine’s valves close and open timely. This is an important aspect of the combustion process; consider it a key to its efficiency and performance. Spark plugs combust the air-fuel mixtures in a gas engine when the plug enters the engine through the inlet valves.

If the timing belt is worn out, the engine’s combustion cycle is disrupted. A bad spark plug will cause inefficient ignitions of the fuel for combustion. All these factors together can affect the overall performance of the engine.

Although these components generally have a long-life cycle, they need to be changed as prescribed.

4. Stick To Service Intervals

You have to maintain your vehicle’s prescribed service intervals. This goes for any scenario, regardless of how you drive your car: when you leave your car unused for extended periods, it can jam up the components and increase the wear.

Stick to your service schedule, and that will help you check your engine’s regular performance and diagnose any problems before they create too big a ruckus. Furthermore, try to get your vehicle serviced from licensed dealerships, ensuring your car gets the most care.

5. Practice Better Driving Styles

Adjust your driving style and adapt a way that isn’t too harsh on the components. Constant heavy braking and acceleration will exert more stress on the components. In addition, make sure you stay in the correct gear for your speed. Not only does this not add unnecessary stress on the engine, but it also keeps the engine running smoothly.

Another mistake is changing the gear to neutral suddenly. We highly recommend choosing the right suspension type for the road you’ll be driving on. Do thorough research on the road infrastructure of your area. For butter smooth roads, a stiff suspension is preferred. On the other hand, a bumpy ride can damage stiff suspensions.

Blown Engine Repair Costs: What You Need to Know

- A blown motor is a costly repair and can exceed the current value of your car.

- Lack of maintenance, low engine oil, and over-revving are the three main causes of a blown engine.

- Symptoms of a blown engine include blue or white exhaust smoke, rattling or knocking in the engine, and coolant in the engine oil.

- Different failures can be categorized as a blown engine, such as blown pistons, a hole in the engine block, or a blown rod.

- Some car manufacturers have more than their fair share of engine problems, such as Audi’s excessive engine oil consumption, BMW’s broken timing chains, and Honda’s Earth Dreams engines leaking fuel into the oil.

- To diagnose a blown engine, a mechanic will need to check engine compression, inspect for leaks, diagnose for misfires, and read diagnostic codes.

- Blown engine issues are a significant concern when considering Hyundai and Kia engine problems.

- Mazda’s 3.0-liter V6 engine is prone to broken timing chains and spun connecting rod bearings.

- Porsche’s Carrera, Panamera, and Boxster models all have known issues with engine failure.

- Toyota engine problems have included V6 engine failure on Highlander models and excessive oil consumption on several models.

Conclusion

Proper vehicle maintenance is critical in extending the service life of your vehicle. A blown engine can be avoided by adopting a handful of healthy practices. Regular oil changes are great at keeping the engine well-greased and running smoothly.

Speeding for too long and pushing your car past suggested RPM levels harm the engine badly. Aftermarket turbocharging kits or other modifications, when used incorrectly, can damage the engine as well.