Mazda has always been known to be an experimental company, as is proven with creations like the 13B engine. It’s a carmaker that’s not afraid to push the envelope, and this is perfectly demonstrated in its development history. Even now, they’re the ones leading the charge at keeping internal combustion engines alive with their Skyactiv-X lineup of engines.

Rotary Engine

However, nothing Mazda makes today can quite compare to their stint with the rotary engine. Nowadays, Mazda is hinting at reinvolving themselves with hydrogen-based rotary engines. But back then it had put all their main interests in rotary engines.

It wouldn’t be far-fetched to say that Mazda believed rotary engines to be the best alternative after reciprocating piston engines. And it’s fair to believe so too, as Mazda has single-handedly pushed the rotary engines to the mainstream.

Without Mazda, the Wankel rotary engines would’ve likely remained largely unknown and foreign to many. It’s Mazda’s unwavering effort to differ from the rest of the market that expanded rotary engines to the state it is today. Even today, the rotary engines garner a sizable fanbase, simply because there is no alternative.

Nevertheless, there are reasons that rotary engines fail. And while Mazda has produced dozens of different rotary engines, not all of them were successful. In fact, it’s fair to say that their latest volume-production rotary engine, the 13B-MSP (RENESIS) put the final nail in the coffin for future mass-production rotaries.

That said, frequent trials and learning from the results mean that Mazda must’ve gotten it right once for it to persevere with rotary engines as a whole. Look at Porsche, who has made the rear-engine rear-wheel driven 911, a seemingly daft idea, work.

For Mazda, this came in the form of the 13B engine. It’s the most widely produced rotary engine by far, and for good reasons. The 13B engine struck it just right, providing a fine balance between power, reliability, and affordability.

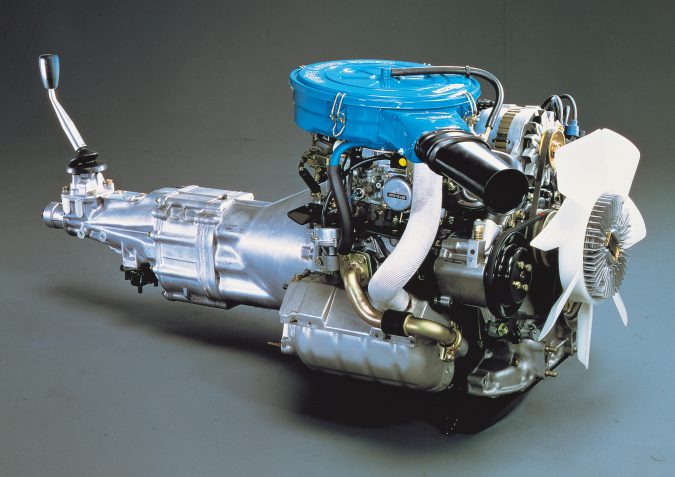

12A Engine

Prior to the miraculously successful 13B engines, Mazda never really stuck with a single design for long. It’s fair to say that its predecessor is the 12A engine. This was the first rotary engine that Mazda found worthy as an alternative powertrain for their production cars.

It’s also this engine that propelled the initial concept of the Rotary Experiment (RX) cars. Little did Mazda realize that they were on to a hit. Its first success came in the form of the RX-3, otherwise known as the Savanna.

Mazda Savanna

The world, and Mazda, were quick to realize the main advantages of the rotary engine – its diminutive dimensions and lightweight. And for the time, the 12A engines, despite displacing just 1,146 ccs, were remarkably potent.

In the RX-3, the engine would produce right around 130 horsepower and 156 Nm of torque. More importantly, the small displacement and dimensions allowed Mazda to design the RX-3 around Japan’s dimensions regulations.

This allowed buyers of the RX-3 to afford a cheaper annual road tax price. The 12A engine would produce more power than its inline peers, while not being penalized by the higher 1.5-liter tax bracket denoted by the Japanese government during the time.

Combined with the stylish muscular coupe styling of the RX-3, Mazda had a hit on its hands. In fact, the RX-3 was so successful that it made up the majority of the rotary engine sales back then.

Even when it came to the races, the RX-3 is a winning formula. It was featherweight and powerful for a naturally aspirated 1.2-liter. In fact, it was one of the first few cars well-sorted enough to compete against the Nissan Skyline back in the 1972 Japanese Grand Prix. Furthermore, it was markedly robust pitted against domestic peers in Australia and the US.

Developing The 13B Engine

Mazda saw the purpose of a more powerful, yet more efficient rotary engine. For Mazda, this meant increasing the displacement of the engine while incorporating newer, emissions-friendly technology. It would go on and dub these engines the 13B.

Perhaps without Mazda anticipating it, the 13B ended up being their most successful design. It’s the most widely produced rotary engine in the world. Despite the nomenclature, it has nothing to do with the 13A engines, which displaced the same, but with different dimensions.

The 13B is actually based on the 12A engine. To extract more power, Mazda developed thicker rotors which elongated the entire housing. Each 13B chamber displaced 654cc, so the 13B ended up being a 1,308 cc 2-rotor engine.

Crucially, the 13B engine was developed with the US EPA Muskie Law standards in mind. Because most RX-3s sold in the US, Mazda knew that this was a massive market that yearns for better fuel economy without strangling power. In fact, while most car manufacturers reckoned that complying with the Muskie Law was impossible, Mazda managed it with the 13B.

13B AP Engine

The first car to be powered by the 13B engine is thus the Luce AP, otherwise known as the RX-4. It was a car that took advantage of the 13B’s low weight and decent output to market itself as both luxurious and sporty. The AP stands for anti-pollution, and the extra displacement was necessary to offset the power losses from the 12A’s emissions regulation device.

With that said, the 13B AP isn’t exactly as well-documented as the other 13B engines. It’s an engine perhaps most well-known for powering the revered Mazda Rotary Pickup (REPU) though, as that remains to be the sole pickup truck to be powered by a rotary engine even today.

Because the main pollutant of a rotary engine is excess hydrocarbon from unburnt gas, Mazda devised a method to improve upon this. This is dubbed by Mazda as a thermal reactor, a primitive emissions device that’s installed right at the exhaust of rotaries of this era.

Essentially, imagine it as a jet engine powered by the 13B’s exhaust gas. It’s double-walled and insulated to maintain efficiency. It begins to function at 600-700 celsius, where the hydrocarbons can combust completely. An air injection pump is utilized to feed cool air around the reactor chamber to prevent overheating.

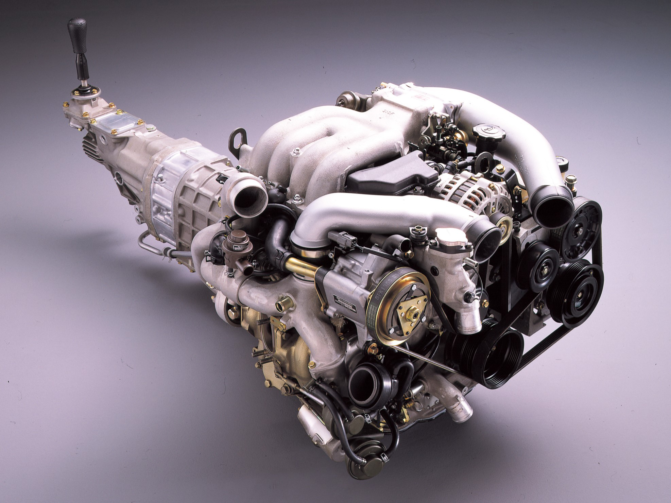

13B AP Engine Design

The thermal reactor was ingenious back then, as it enabled Mazda to clear the US EPA Muskie Act test. By now, Mazda was also working on developing an advanced catalytic converter. The thermal reactor system remained in use until 1980 though. Nowadays, it’s seen as a bit of a nuisance and deleted in the hands of enthusiasts.

However, the 13B AP is really just a 12A engine with extra displacement. It faced one big issue that plagued every carmaker back in the 70s – the oil crisis. The soaring oil prices meant that fuel efficiency was more important than power, and the 13B performed poorly in fuel efficiency terms.

Mainly, the underperforming fuel economy figures were due to fundamentally flawed design in the 12A. It also used a carburetor system that just can’t meter and deliver fuel accurately and effectively enough for the increasingly stringent emissions law and consumer demands.

RX7 Engine

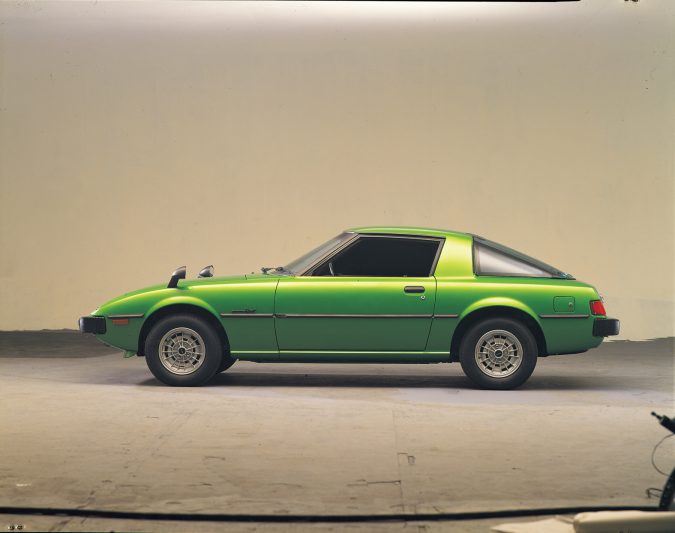

Following the formula of the RX-3, Mazda took note of what made the RX-3 work. Since nearly half of all the RX-3s sold are coupe models, this factored into the design philosophy of the RX-7. A sleek, lightweight, and compact pure sports car.

Introduced in March 1978, the RX-7 Savanna, or FB3S, is the direct successor of the RX-3 Coupe. It mimicked everything that made the RX-3 Savanna a popular option amongst the Japanese, compact size, low weight, and balanced handling.

The FB3S RX-7 still used the same 12A engines with roughly the same output. However, the minimal 1,100 kg weight enabled a sub-10 second 0-60 mph time. Most importantly, the dimensions of a 12A allowed the engine to be placed behind the front axle. This front-mid engine layout would become the staple of RX-7 design.

While the 12A in the RX-7 produces less power than the older 12As, this was due to the emissions control strategy used by Mazda to cope with the regulations. This was all part of the Mazda ‘Phoenix Project’ to revitalize the rotary engine’s image as a viable reciprocating piston alternative. Compared to the earlier 12A, this ‘lean burn’ 12A managed just about 100 horsepower and 135 Nm of torque.

This necessitated improvements to the 12A’s combustion behavior, carburetor design, and also the world’s first rotary engine catalytic converter system. It also involved an improved ignition system and an additional split air injection valve for the two-pellet catalytic converter.

All of the above improvements also allowed the 12A to operate at a leaner fuel mixture without impacting its NOx emissions. This was marketed by Mazda as a lean-burn rotary engine, which by today may be confused by some as a system akin to modern stratified fuel injection engines.

RX7 Rotary Engine

This emissions-conscious 12A engine was known as the 4-port and was used in the Series 1 (SA) and Series 2 RX-7s. Finally, some later Series 2 RX-7s (referred to as the FB) received a further refined 6-port 12A engine.

The 6-port 12As featured 2 additional induction ports that functioned at around 4,000 RPMs. The 6-port 12A also incorporated an exhaust gas recirculation system to further improve emissions. The carburetor was also improved to an auto-choke unit. Power is bumped up slightly to 115 horsepower.

With all that said, despite Mazda’s engineering efforts, the 12A just didn’t produce enough power to entice the higher-end crowd. This is when Mazda developed a turbocharged variant of the 12A. It’s only found in the final Series 3 RX-7s, the Luce, and the Cosmo starting from late 1982.

This 12A served as the basis for future RX-7 engines, as it proved that a turbocharger designed for the purpose can be very beneficial without heavily compromising fuel efficiency and emissions. The 12A turbo ditched the carburetors for electronic fuel injection. The compression ratio is reduced to 8.5:1 from 9.4:1 for turbocharging.

This engine also went through two iterations. The early versions used a bigger Hitachi HT18-BM turbocharger that yielded 160 horsepower and 224 Nm of torque. Later variants, however, used a revised, but smaller, HT18S-BM with a revised turbine wheel design. The blades are better optimized for rotary engine exhaust pulse, and this is dubbed an ‘Impact Turbocharger’ by Mazda. Power is improved to 165 horsepower, but turbo lag is minimized and thus torque delivery is improved.

13B Engine Development

Learning from the 12A Turbo, Mazda went on to further develop the 13B engine. This materialized in the form of the 13B-RESI, an engine only used from 1984 to 1985 in the Luce, Cosmo, and RX-7 (FB3S Series 3). You can identify the 13B RX-7s from the GSL-SE trim level.

13B RESI Engine

The 13B-RESI (Rotary Engine Super Injection) is a naturally-aspirated 1.3-liter 2-rotor engine that produces 135 horsepower and 180 Nm of torque at just 3,500 RPM. It’s a big improvement over the earlier 12A models, so this is one of the ultimate

Most remarkably though is the improved fuel economy figures. Combined, the 13B-RESI is rated for approximately 25 mpg. Time for 0-50 mph is achieved in 6.3 seconds. The main changes from the 13B AP are found in the fuel delivery system and intake system.

The 13B-RESI utilizes a Bosch L-Jetronic fuel injection engine with a single fuel injector located at the intake port of each rotor chamber. Without turbocharging though, the 13B-RESI utilizes an early iteration of intake supercharging. It’s a two-level intake system to improve low-end output without impacting top-end power.

Of course, any keen Mazda fan would recognize this as an early iteration of Mazda’s variable intake system. It’s one of the best adopters of variable intake technology. In fact, the RENESIS engine nowadays has multiple stages of intake valve control to make the best out of the rotary engine’s intake characteristics.

Internally, these 13B-RESI engines only resemble the 13B AP engines. However, it features reliability improvements from Mazda better understand the flaws of a rotary. Notably, Mazda implemented a high-flow oil pump from the 12A Turbo as well as an in-housing oil squirter near the air inlet.

13B DEI Engine

Following the 1986 launch of the second-generation FC3S RX-7, Mazda needed newer and improved engines to power the car. The FC3S was initially available with two engines, the non-turbo 13B-DEI and the turbocharged 13B-T. At this point, the 12A engine was mostly phased out of use.

Mazda put more emphasis on a few key points of these new 13B engines. Mainly, Mazda intended for better output throughout the operating range, increase redline to enthrall drivers, improved engine response, better fuel efficiency, and reduce oil consumption.

Despite remaining a 1.3-liter naturally-aspirated 2-rotor engine, Mazda managed to extract more power out of the 13B-DEI. At 146 horsepower and 187 Nm of torque, even non-turbocharged RX-7s feel quick enough to entice regular consumers.

Improvements came mainly in improving combustion quality by revising the DEI’s intake and fuel delivery systems. The 13B-DEI employed two additional auxiliary ports, thus using a 6-port induction (6PI). It’s an innovation over the more primitive 2-level, 6-port induction system used in prior 12A 6-port engines.

Was The 13B-DEI Engine Really That Good?

Additionally, Mazda also incorporated a dual-fuel injector system in lieu of the single injectors found in early fuel-injected rotary engines. Again, it’s an early iteration of modern dual fuel injector rotary engines.

Similar to newer rotary engines, there’s a set of smaller and larger injectors. The idea is that the smaller injectors provide better fuel delivery characteristics and atomization at idle to low RPM ranges. The larger injectors can then supply the additional fuel required at the higher rev range.

Thus, stable combustion can be maintained at low speeds. This means the engine emanates less excess unburned hydrocarbon and thus returns cleaner emissions. It’s a system that is now commonly incorporated in rotary engines.

A few years later in 1989, Mazda introduced the facelifted Series 5 FC3S with an improved variant of the 13B-DEI. This new 13B-DEI touts better engine management, a revised intake manifold, and a 9.7:1 higher compression ratio as well as a lightened rotors. Power output is improved to 160 horsepower and 190 Nm of torque.

13B T Engine

However, despite the improved output of the naturally aspirated engines, the turbocharged FC3S is what really captured international buyers’ attention. Previously, turbocharged rotaries are a relative scarcity. In fact, turbocharging an originally naturally aspirated rotary is no simple feat.

The turbocharged 13B-T was one of the first widely accessible turbocharged rotary engines for the public. In its initial configuration, the 13B-T puts out 182 horsepower and 248 Nm of torque. These variants with the turbocharged engines are known as the RX-7 ‘GTR’.

In lieu of a 6-port design, the 13B-T actually reverted back to the more traditional 4-port intake design. The dual injector design remained in use though. Later Series 5 RX-7 ‘GTX’ utilizes a higher compression ratio at 9.0:1 along with other updates found in the non-turbo variants. The output is increased to a remarkable 200 horsepower and 265 Nm of torque.

The 13B-T engines are often praised amongst the rotary enthusiast community for responding positively to aftermarket modifications. With flow improvements on the exhaust side, larger injectors, and a programmable engine management system, it’s not difficult to make approximately 250 horsepower out of these engines.

Combined with the relative abundance of these engines, it’s a recommended alternative for those who intend to turbocharge their naturally-aspirated 12A or 13B engines. However, it is an early experimentation with turbocharged rotary engines by Mazda, thus the 13B-Ts had a few design flaws that limited their maximum output.

Regardless, if you’re looking for a turbocharged rotary engine, and aren’t looking to make big power, then these 13B-Ts engines are a good option other than the expensive 13B-REWs. The 13B-T also found its way into the Mazda HC Luce (or 929), among many other engines that Mazda opted to power their luxobarge.

13B RE Engine

In the late 1980s and early 1990s, carmakers in Japan were stepping it up in an arms race. Everyone was competing against their peers. Manufacturers would race to incorporate some genuinely cutting-edge technology into their halo cars. In this competition for one-upmanship, Mazda enjoyed the distinct advantage of being the only company offering rotary drivetrains.

For Mazda, their halo car was the JC Eunos Cosmo. It was Mazda’s ultimate display of luxury, showing the world that they’re capable of making a grand tourer that rivals Lexus. It’s also esteemed for being powered by the only production 3-rotor engine ever offered by Mazda, the 20B-REW.

However, the Eunos Cosmo was also offered with the comparatively modest 13B-RE. In fact, more Cosmos powered by the 13B-RE were sold than 20B-powered Cosmos. It’s a sequentially turbocharged 1.3-liter 2-rotor engine producing 227 horsepower and 294 Nm of torque.

The Cosmo is especially noteworthy for boasting the first commercially-available sequential turbo rotary engine. To counteract the low torque nature of rotary engines, a Hitachi HT-15 primary, and Hitachi HT-10 secondary provides an extra boost when needed.

In fact, such a system was efficacious for achieving the Eunos Cosmo’s vision – the epitome of a Mazda grand tourer. The Cosmo 13B-RE engine made its peak torque at 3,500 RPM, optimal for cruising on motorways. Boost is limited to a modest 8 psi.

The 13B-RE is often remarked to feature some of the biggest stock intake ports offered on the production 13B engines. It also sports an intake manifold with bigger runners. Though the 13B-RE is often dismissed for its inability to sustain high RPM operations and restrictive exhaust sleeves. Of course, it’s also as difficult to source as a 20B engine.

13B REW Engine

Alongside the 13B-RE’s development is the 13B-REW. This is the ultimate 13B engine that most people think about when they think of rotary engines. Powering the 1992 RX-7 FD3S, it’s also the most powerful stock 13B engine that Mazda makes.

Many parts are shared between the 13B-RE and 13B-REW. However, with some major differences, the 13B-REW actually makes a lot more power than the 13B-RE. In fact, during its initial launch, the 13B-REW would’ve put out 250 horsepower and 294 Nm of torque.

Rather than sizing two different turbochargers, both turbos on the FD3S are Hitachi HT-12s. With two identical turbochargers, Mazda staggers the charge air for better response. Basically, the primary turbo spools as a single first, feeding only minimal exhaust energy to the secondary turbo.

Only until the secondary turbo is fully ready then a flap open to feed equal amounts of exhaust to it. It’s a decidedly impressive system given the constraints Mazda engineers worked with. However, its torque delivery is only semi-linear at best. For more on the sequential turbocharging system, read here.

Was The 13B-REW Really That Good?

By monitoring the boost levels, it’s overt that the boots go from 10 psi below 4,500 RPM to suddenly dropping to 8 during 4,500 RPM before building back up to 10 psi all the way to redline. This famous 4,500 RPM transition is what often catches novice FD drivers off guard in the corners. It also earnt the RX-7 the reputation of being tricky to drive properly.

Mazda also made multiple key refinements to the 13B-REW for it to appeal as a true sports car engine. For one, oil pressure is increased despite sharing the same oil pump in the 13-RE. The rotor bearing is improved to a 9-window design. Exhaust sleeves are enlarged. The stationary gears are also strengthened.

Therefore, despite being a similar engine to the 13B-RE, the 13B-REW can sustain engine operations at 8,000 RPM, making it the definitive enthusiast’s rotary engine of choice. It’s also where the extra horsepower comes from. The output is eventually improved to 276 horsepower and 314 Nm of torque by the end of the FD3S’s life.

Facts about the Mazda 13B Engine

- The 13B engine is a Mazda Wankel engine produced over 30 years and featured in several Mazda models, including the RX-7.

- The 13B engine has a two-rotor design with a total displacement of 1.3 liters and looks like a lengthened version of its predecessor, the 12A.

- The 13B engine was initially equipped with a carburetor fuel system and single distributor in the ignition system, later switched to injection.

- The 13B-RESI engine introduced in 1984 features a Bosch L-Jetronic fuel injection system and a unique intake manifold with a two-level intake box that provides a supercharger-like effect, improving power and torque of naturally aspirated 13B engines.

- The 13B-DEI engine is a non-turbo engine equipped with the 6PI, DEI systems, and four-injector electronic fuel injection, providing 146 hp and 138 lb-ft of torque.

- The 13B-T engine features a single twin-scroll turbocharger and the four-injector fuel injection from the 13B-DEI, providing 185 hp and 183 lb-ft of torque.

- The 13B-REW engine is a completely redesigned 13B engine, featuring twin sequential turbochargers, two big Hitachi HT-12 turbos, and an air-to-air intercooler.

- The 13B-REW engine was fitted with hardened apex seals to manage high boost and additional loads, thin wall cast-iron rotors, four platinum-tipped spark plugs, and enhanced cooling, revised intake, and a better lubrication system.

- The 13B engine is not practical for daily drivers due to low fuel economy and requiring more care, but it can be as reliable as a piston engine with regular maintenance and proper oil and gas.

- The engine burns oil, and it is essential to keep an eye on oil level and oil pressure. Premixing oil in the gas is a simplified method of extending the engine life, and preventing overheating is crucial by changing the coolant and thermostat every 12-18 months and inspecting the hoses and belts.

Verdict On Mazda’s 13B Engine

The 13B engines are an enduring staple in Mazda’s history as a whole. In fact, if it wasn’t for the 13B engines, it’s likely that Mazda won’t be as doted as they are now. The 13B-REW is one of the best rotary Mazda has produced. Along with the FD3S’s brilliant engineering and timeless design, it’s not hard to imagine why it’s so beloved.

It’s perhaps why many treat the RENESIS as a step back for Mazda. It’s illogical to say that when both engines are built at different times with different priorities in mind. That said, it can be argued that most Japanese car manufacturers have not quite outperformed themselves 2 decades back.

FAQs On Mazda’s 13B Engine

If you’re still curious to learn more about Mazda’s 13B engine, our FAQs here might help…

What Is A Rotary Engine

Rotary engines were originally used to power aircraft, but in the mid to late 20th century, made their way into cars. At its core, it still maintains the 4 combustion cycles as a conventional piston engine that most vehicles use. These cycles are the Intake, Compression, Combustion, and Exhaust. However, while most engines use pistons that reciprocate up and down during a combustion cycle, rotary engines adopt a triangular-shaped rotor or disc that rotates in a circular motion. As this rotor rotates, it creates 3 separate gas-tight seals within a cylindrical combustion chamber. These 3 voids contained by the rotors function similarly to pistons – allowing air and fuel to enter, compressing this mixture, and igniting them to create power. Then, the by-products of that combustion are exhausted out of the engine.

Are Rotary Engines Reliable

It depends on what you define reliable as. Rotary engines are generally pretty dependable, as they don’t frequently suffer from breakdowns or random issues that might impact their usability and performance. Therefore, you don’t always have to worry about unexpected problems. However, rotary engines aren’t as robust as piston engines and don’t last nearly as long. Sometimes, they require an extensive rebuild every 100,000 miles (while piston engines can last 200,000 to 300,000+ miles). Moreover, rotary engines are often incredibly high maintenance and require very frequent servicing. In particular, they like to drink oil and overheat easily. As well as, rapidly accelerating the wear on your ignition components (i.e. the spark plug, ignition coil, etc.). Rotary engines also have a very poor fuel economy.

What Cars Have Rotary Engines

While rotary-powered cars are synonymous with Mazda today, they weren’t the first automaker to use a rotary in a production vehicle. This would be the NSU – a small and now-defunct West German brand – with its Wankel Spider. Nevertheless, Mazda would be the only automaker in the world to have developed and integrated rotary engines the longest. And, they’re the most prevalent. The first Mazda production car to come with a rotary was the Cosmo Sport of the late 1960s. Since then, they’ve put a rotary engine in every class of vehicle, from pickup trucks to sports cars. They’ve also put a rotary in various race cars, like the legendary 787B. Other iconic rotary-powered Mazdas include the RX7 and RX8. Though, the latter would be the last production car to date that was powered by a rotary engine, being discontinued in 2012.

Are Rotary Engines Good

Rotary engines are revolutionary in many regards, though not without their downsides. Compared to traditional piston engines, rotary engines are relatively lightweight, have a lot fewer moving parts, and are more power-efficient. The latter means that a small-displacement rotary could produce enough horsepower to match a piston engine of a larger displacement. They can rev pretty high up in the power band, and in the right hands, they’re a pretty fast motor. Granted, they lack grunt and shove in the lower RPMs. There are other downsides to rotary engines. Because you need to rev them so high, they’re very bad with fuel economy. Additionally, rotary engines require very frequent servicing, as they tend to drink up a lot of oil. Ignition parts also wear out quicker. Plus, they heat up more readily and emit comparatively more emissions.

How Many Cylinders In RX7

The Mazda RX7 is powered by a rotary engine. Thus, it doesn’t have any cylinders, but rotors – as is the nature of how rotary engines work. The RX7 has a 1.3-liter, twin-turbo, twin-rotor engine, so-called the 13B. Now, trying to find a cylinder equivalent to the RX7 is rather interesting. A rotary engine fires 3 chambers within a single complete revolution during its combustion cycle, per rotor. If you’d multiply that with 2 rotors, then the RX7’s engine is somewhat equivalent to a V6 or inline-6. However, some would dispute this, as the output shaft on a rotary engine rotates very rapidly. In certain configurations then, only 2 chambers per rotor would fire per revolution. In that case, you could also compare a twin-rotor engine to a high-spec V4 or inline-4.