When you own a car powered by a rotary engine, like the 20B engine, it’s inevitable that you’ll yearn for more power. Because of the unique way a rotary operates, it inherently produces less torque than conventional piston engines. That’s the main reason Mazda had to resort to forced induction to improve output.

However, for many, the relatively modest output of the 13B engines isn’t quite enough to satisfy. In fact, the lack of torque is a major quibble with the 13B-MSP (RENESIS) engine found in the RX8. Combined with its relative popularity and handling capability, it’s no wonder that people sought to squeeze more out of the RX8.

In fact, the aftermarket industry has attempted to improve upon the RENESIS’s power output for a long time. From minor intake and exhaust work to ECU remaps, and finally forced induction kits. With the RX7 and its 13B-REWs and 13B-Ts, it’s an even broader market.

However, despite its positive response to modifications, the limitations of a low displacement engine are clear. Little to no low-end torque, and a compromise between turbo size and response. A turbo or supercharger will massively improve torque output, but not at the low-end.

Rotary Engine

If you want to improve the lack of low-end torque, one of the best ways is to improve engine displacement. A supercharger can help, but that causes parasitic losses and increases complexity and fuel consumption. The best way is to improve engine displacement.

In a piston engine, that would typically mean increasing the number of cylinders. Within a rotary engine, the equivalent is increasing rotor count. In fact, this is something that Mazda themselves have explored prior in their prototypes and experimental vehicles.

The most rotors they’ve put in a car is the 4-rotor or referred to as the 26B. It was used in the 787B predominantly. That was Mazda’s car for its 24 Hours of Le Mans program. In fact, it ended up being the only car powered by a non-piston engine to win the race outright.

In the 1991 24 Hours of Le Mans, Mazda’s 26B-powered 787B was exemplary. Not only did the engine run without a hitch, but it was also fuel-efficient enough to not require a conservative driving strategy. And, following that, car #55 won the 1991 24 Hours of Le Mans. It also simultaneously broke the record for most laps crossed and distance traveled.

20B Rotary Engine

The 787B was legendary, but the 26B proved too unfeasible for a volume production engine. It was too expensive and complex to produce. However, the less known 767B was powered by a 3-rotor engine dubbed the 20B.

With further experimentation by Mazda, it deemed the 20B to be a good compromise between power, reliability, and cost. In fact, the behavior of the 20B is comparable to an inline-6 engine. This means that the engine was impeccably smooth and predictable.

Therefore, Mazda, seeking to capitalize on the halo car market, developed a 20B engine capable of powering a road vehicle. Dubbed the Cosmo and sold under Mazda’s premium marque Eunos. So far, it remains the only mass-production road car propelled by a 3-rotor drivetrain.

Eunos Cosmo

Mazda’s Cosmo lineup of cars is enduring, being produced from 1967 to 1995. It had served the sole purpose of being Mazda’s ‘halo car’. This means it represented the best of Mazda’s road car engineering prowess. However, no other Cosmo (bar the original) has quite captured this ‘halo car’ philosophy as the third-generation JC Eunos Cosmo.

The Eunos Cosmo was truly the best of Mazda’s luxury car design. Initially debuted in 1990, Mazda developed the then-new Eunos Cosmo on the completely standalone JC platform. It’s a platform intended for full-size luxury rear-wheel-drive cars and ended up only used by the JC Eunos Cosmo.

Without the need to conform to Japanese dimensions regulations, the Eunos Cosmo didn’t quite perform so well in terms of sales compared to past models. However, it set several industries’ firsts. Notably, it was the first production car to offer a built-in GPS navigation system.

Furthermore, it also sets the precedent for offering the sequential turbocharging system to the mainstream market. Mazda sold the Cosmo with two engines available – the 13B-RE and the 20B-REW. The latter being both rarer and now more desirable than the former.

The 20B-REW in the Eunos Cosmo is referred to as the production 20B. In this guise, it’s remarkably powerful, putting out 300 horsepower and 403 Nm of torque thanks to the combination of 2.0-liters and sequential turbocharging at just 0.7 bar of boost.

Being only sold with a 4-speed automatic, Mazda meant for the Eunos Cosmo to be completely segregated from the RX7. Not only did the 20B-REW offer more power, but it also provided tons of low-end torque and smoothness on par with an inline-6.

20B Engine Variations

The 20B-REW found in the Eunos Cosmo is the most common 3-rotor you can find, and perhaps one that most are familiar with. However, Mazda actually conceptualized and produced a lot more 20Bs than the production 20B-REW.

13G Racing Engines

While technically not dubbed a 20B, the 13G is the predecessor to the 20B. It’s a 3-rotor engine initially used by Mazda in racing for the lesser-known Mazda 757. It got off on the wrong foot though, as both Mazdaspeed 757s that entered the 1986 24 Hours of Le Mans suffered from transmission failure and did not finish.

Following that though, the 757 enjoyed decent success and merited Mazda to further push their racing program. The 13G racing engine remain used in the 757 until about 1988, by then the engine had proven its viability for production use.

The idea of the 13G came about due to the modular nature of a rotary engine. By stacking the existing 13B housings, Mazda could carry over most major parts without the need for different block designs. It’s also an immensely powerful engine weighing just 143 kg, producing 440 horsepower at 8,500 rpm and ~400 Nm of torque at 8,000 rpm.

Some one-off parts had to be manufactured though. Primarily an elongated eccentric shaft, different intermediate housing with a phasing gear, and different front housing design. While the modularity and compatibility save on cost, the eccentric shaft proved to be particularly tricky and expensive to manufacture.

13G Performance

Prior to the 13G, previous 3-rotor designs were just experimental and based on the 13B eccentric shaft. The older designs use keyways to phase the lobes together. However, this design proved to be flawed when it comes to rigidity.

In the 13G, it was still a 2-rotor shaft with modifications for 3-rotor use. However, now it has an extension ‘snout’ that extends all the way to the front shaft pulley. Then, there’s a separate eccentric shaft sleeve that indexes into this extension. There is a tapered section to fit the two sections together to improve overall shaft strength.

Then, the two separate shafts are phased together via a small key. Here are some pictures of the 13G eccentric shaft. A spacer (like the thrust washers in piston engines) serves to tension the shaft and pushes the extension sleeve into the tapered section.

13G Production Engines

Following the relatively successful results from the racing program, Mazda started exploring the applications of the 3-rotor in a road car. This came in the form of the Mazda MX-03, a concept car that eventually served as the foundation of the JC Eunos Cosmo.

For street use, the 13G 3-rotor engine had to be tamed. It’s still 2.0-liters, but it borrows most of the production parts from the 13B engine. Intriguingly, like the 13G racing engine, the production variant also utilized a dry-sump system.

However, rather than squeezing every bit of power it could naturally, Mazda resorted to forced induction. This is mainly to improve the torque delivery, as the 13G racing engine would require significant revving for power.

For comparison, the production 13G would only produce 315 horsepower at 7,000 rpm. However, It also makes ~400 Nm of torque, albeit at just 3,800 rpm. The racing engine would require 8,000 rpm to produce peak torque. This demonstrated that even with a larger displacement engine, turbocharging is the way to go for street use.

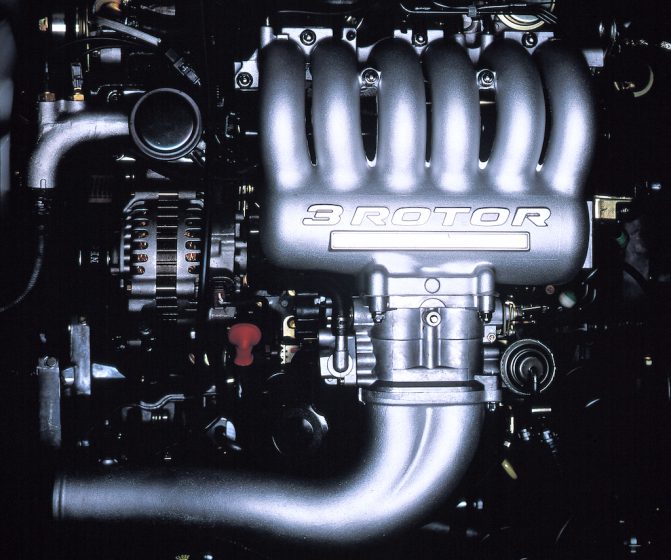

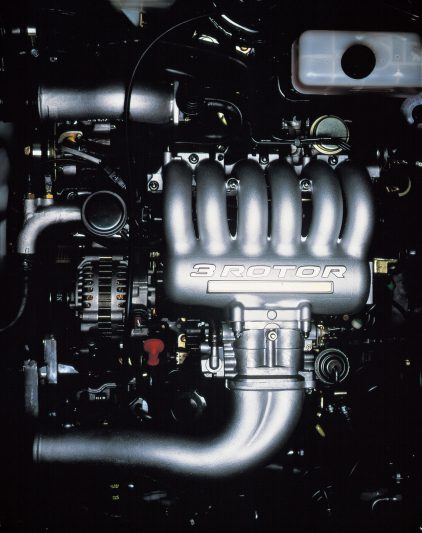

20B-REW Engines

This is the best-documented Mazda 3-rotor engine and the easiest one you can source. It’s a 2.0-liter sequentially turbocharged engine. If you want a 3-rotor RX7 or RX8, finding a 20B-REW half-cut from the yard is your best bet.

That said, don’t think it’ll be remotely affordable. The 20B-REW is unique in that it’s an engine solely built for just one car, the JC Eunos Cosmo. And to further complicate things, the 3-rotor Eunos Cosmos was only available in Japan. This means that any 20B-REW half-cut must be imported.

The 20B-REW produces a rated 276 horsepower and 400 Nm of torque, with it making the bulk of its torque from 1,800 rpm onwards. This makes it pleasant for long-distance driving. However, the complex sequential turbocharging pushed the weight to 350 kg.

Much like the construction of the 13G production engine, for the 20B-REW to be production viable, Mazda borrowed parts from the 13B engines. Obviously, some custom parts are necessary, such as a 3-rotor eccentric shaft and second intermediate housing.

Furthermore, the 20B-REW shifted towards a distributor-less ignition system while retaining the original distributor pickup mechanism. There’s also a 3-rotor intake and exhaust system with turbocharging in mind.

The Eunos Cosmo is produced from February 1990 to September 1995 with an estimated 4,000 3-rotor variants sold. Therefore, the 20B-REW is actually segregated into several different batches identifiable from its engine number.

20B-REW Reliability

The first run engines were the initial 2 batches, numbered 000-999 and A000-A999. These are the problematic ones, and most were rebuilt under warranty by Mazda. The issues concerned the intermediate housing, and the rebuilt engines can be recognized via rotor housings marked black without batch number stamps.

Because the first run engines had such a short lifespan, you’ll scarcely see a stock one being sold. The housings would fail under short notice, and it’s the second-run engines that addressed this issue. Reportedly, these first-run engines also experienced eccentric shaft failure.

These second run engines are numbered B000-B999 and C000-C999 respectively. With the reinforced housing, the 20B-REW engines are capable of handling substantially more, they are reliable and durable. Enthusiasts love these engines for their boost-handling capability and thus potential power output.

The final 20B-REW runs were numbered D000-D999 and E000-E999. There are no F-series 20B-REWs around, and the E engines might only exist to be sold by Mazda or used for warranty replacements only. Through the 20B-REW engine, you can identify the Series 2 Cosmos (93-95), which had a black intake manifold. Series 1 Cosmos (90-92) had silver intake manifolds instead.

20B Racing Engines

Finally, there’s the holy grail of the 20B engine. Mazda had been selling parts for their racing 20B engines beyond the 20B engine’s actual lifespan. This is part of their Mazdaspeed Racing Support Program. It’s assumed that the 20B racing engines are actually based on the 13G racing engines though.

This assumption is made primarily due to the nigh identical power and torque figures at the same rpm (440 horsepower and near 400 Nm of torque). The dimensions and weight are almost alike too. It’s also a dry-sump engine, which is common for race applications.

Even today there are aftermarket suppliers that provide parts for the 20B engine. Atkins Rotary (US) is a prominent supplier for 20B parts, for example. And if you are patient enough, there are genuine race-spec 20Bs up for sale in the classifieds.

With that said, trying to keep a genuine race Mazda 20B engine running is getting increasingly difficult nowadays. Parts are dwindling every day, and it’s not quite so simple to assemble a complete engine. It’s also impressively expensive to upgrade a 20B engine, so it’s solely for the rotary enthusiasts with means.

Why Run The 20B Engine?

If the 20B engine is so expensive and unrealistic, why do many still run this engine? The answer is that even when stock, the 20B-REWs provide adequate power for most and don’t upset the balance of RX cars that much.

And while parts support from Mazda themselves is essentially non-existent nowadays, people are beginning to produce custom replacement parts for the 20B engines. In fact, the folks over at Promaz (AU) can machine you a billet housing given that you have the budget for it.

Moreover, the 20B engine is just a logical step for many who want to run a street-able rotary engine with great power and response. With a 13B, you can only make so much power before being flow limited, even after porting. And when you port a rotary engine, it becomes less and less drivable on the streets.

That’s not to underestimate the capabilities of the 13B, because folks have run these engines routinely to over 400 horsepower while remaining street driven. But what if you want more? There’s no way around it, a 20B ultimately has more charge flow potential than the 13B engine.

20B-REW Performance

This is why the 20B appeals so much to racers and normal gearheads alike. It’s also sustainable enough to run long-term without needing custom parts machined all the time. For street cars, a 20B-REW with uprated turbo and porting can produce upwards of over 600 horsepower without too much issue. That’s plenty for a weekend warrior.

For the time trial drivers and drag racers, the 20B engine offers immense potential and great response. When built naturally aspirated, it still produces good power while weighing very little, which makes it an ideal proposition for something like a rally car, or a circuit racer.

Of course, beyond the obvious power benefits of running the higher displacement 20B engines, there’s an overt rationale behind most 20B builds – it’s cool. If you want the sound of a 3-rotor, you have to get a 3-rotor, it doesn’t sound remotely like anything produced by anyone even today.

And if you want to stand out from the numerous turbo kit RX8s and single turbo RX7s, the obvious choice is a multi-rotor engine. The 20B-REW remains approachable enough for a devout rotary fan to consider a conversion. And I think it’s pretty cool when you own a 3-rotor-powered anything.

Naturally-Aspirated Or Turbocharged 20B Engine?

Although we like turbocharging, the 20B is an engine that’s eccentric enough to appeal to enthusiasts who are willing to experiment. Of course, we know the 20B as a turbocharged engine, as there are far more 20B-REWs around compared to the 20B race engine.

However, there’s always the option of losing the turbochargers on a 20B-REW. Therefore, you might be stuck in the middle of deciding whether to build a naturally-aspirated 20B or a turbocharged one.

Turbocharged 20B Engine

Running a turbocharged 20B-REW is the clear consensus here. For one, it’s a lot simpler, as the engine comes turbocharged from the factory. From here you should decide whether to run the stock sequential or go for a single turbo conversion.

The stock sequential turbos of the 20B-REW will start to strain once you attempt to push 1 bar of boost. As the engine is designed more for below 8,000 rpm, low-end operation, the stock twins are optimal for the purpose. With mild modifications and aftermarket ECU management, you can expect just over 300 WHP out of a healthy 20B-REW.

With the stock Hitachi HT-10 and HT-15 twins, flow quickly becomes restrictive. The stock boost pressure is just ~0.7 bar after all. If you want to stick with the stock twins, but want more power, you can opt to run the twins non-sequential. This means eliminating the whole switch-over and vacuum flap system for more overall system flow. It also gets rid of most of the complications found in the sequential system.

Turbocharged 20B Engine… Good Or Bad?

If that’s insufficient, then you have the option of upgrading the turbos. This can be done by hybridizing the turbos or even replacing them with larger ones. This is a service offered by PettittRacing (US) and BNR Supercars LLC (US).

The simpler way is to go for a big single turbo. People have run massive turbochargers on the 20B while making over 600 WHP this way. Of course, you’re going to end up with a peaky torque curve, but the 20B’s displacement allows it to spool large turbos relatively quickly. It’ll still be appreciably potent even off-boost. It’s also simpler to run a single turbo system with aftermarket engine management.

For the conversion, you used to need custom exhaust work. However, now you can order a single-turbo exhaust manifold from Turblown directly. The turbo option depends on your power requirements, but the size for a 4.0-liter engine. To give you an idea, the massive GT42 is a common option, with people opting for even bigger turbochargers just to provide enough charge flow for engine operation.

Naturally-Aspirated 20B Engine

Despite the obviously superior power output of a turbocharging system, there are also a fair few who opt for a naturally-aspirated 20B. There are two ways to approach this as well, either you get lucky and score a race 20B engine, or you forsake the turbos on a 20B-REW.

This is probably the least pragmatic way to go about a 20B conversion. A racing 20B engine is exorbitant, and running a 20B-REW turbo-less requires extra work that costs more to yield less power. However, if you want a banshee-esque wailing exhaust note, then this is your ticket.

Needless to say, running it this way you’re going to need a custom intake, exhaust, and engine management system to best optimize it. Running a semi-peripheral port paired with an individual throttle body setup also provides a better low-end response while flowing enough air to sustain high rpm operation.

Naturally-Aspirated 20B Engines… Good Or Bad

However, it’s worth noting that without a proper rebuild or custom 20B engine assembled for naturally aspirated, you won’t be making much power at all. The 20B-REW isn’t made to operate at high revs all the time. Without supporting mods, the engine wouldn’t facilitate continuous 10,000 rpm runs. If you want a properly done NA 20B, then Defined Autoworks (US) is one of the best in the business to speak to.

However, the advantages are clear. As we know from the 13G racing engines, when built naturally aspirated, a 3-rotor can weigh as little as 143 kg. That’s considerably less weight compared to a turbocharged system. And any weight shed off the nose is critical for a properly balanced track car.

Other than that, a naturally-aspirated 20B engine will have far fewer complications when compared to the 20B-REW engine. It also offers a screaming exhaust note that you lose when stifled by turbochargers. Furthermore, a naturally-aspirated 20B will tout a very linear, but torquey powerband that can be ideal for a tight-circuit racing car.

Facts about Mazda’s 20B Rotary Engine

- The 20B engine is Mazda’s only production 3-rotor motor ever made and is considered the “big block” of the rotary world.

- It was the world’s first mass-produced 3-rotor engine with a twin-turbo setup, with the Racing 20B engine being an upgraded version of their 13G engine with increased power and torque numbers compared to the 20B-REW engine.

- The 20B rotary engine was used in only one stock vehicle, the Mazda Eunos Cosmo, which was only available in Japan and was produced from 1990 to 1996.

- The Eunos Cosmo with a 20B engine can cost anywhere between $20,000 to over $50,000 depending on the car’s condition and mileage due to the car’s rarity, luxury status, and the high cost of importing them from Japan.

- The 20B engine is significantly more powerful than the smaller 13B engine, which was used in many different vehicles over the years, including the RX-7.

- Upgrading the 20B-REW for significant improvements can cost upwards of $15,000 if you do the work yourself or $25,000 to $35,000 if you hire someone else to do it.

- Regular maintenance on a 20B rotary engine involves keeping up with oil changes, spark plugs, coolant changes, and other regular engine maintenance, but maintenance performed on rotary engines can be more expensive due to the lack of mechanics trained to work on them.

- A properly cared for 20B rotary engine should last anywhere from 150,000 to 300,000 miles or more, but without a comprehensive maintenance history, it is difficult to determine the engine’s reliability, and a rebuild can cost between $3,500 to $4,000.

- While the 20B engine was only sold in Japan, enthusiasts can engine swap a variety of vehicles with enough custom work and money.

- Independent tests have verified that the 20B engine can safely be pushed to 9000 rpm if the transmission is upgraded, significantly upgrading its output capabilities.

20B Engine Verdict

Despite its relative obscurity and the exorbitant price of admission, the 20B remains a popular engine for rotary enthusiasts. It offers character that’s just not found in conventional engines, with even the stock 20B-REW being ample for most.

Want a 20B engine yourself? Then one of the simplest ways is to search for a 3-rotor JC Eunos Cosmo. There’s a huge fanbase around this car, and there is plenty of information going around to ease the process. If your budget permits, then building your own 20B engine is possible too, with the help of professionals.

FAQs On 20B Engines

If you’re still curious to know more about 20B engines, our FAQs here might help…

Does Mazda Still Make Rotary Engines

Back in the day, Mazda first decided on powering its cars with rotary engines mostly as a marketing stunt. In short, to differentiate themselves from the other automakers at the time. However, Mazda proved rather proficient with engineering its rotary powertrains and kept developing them from the 1960s onward. Mazda not only included a rotary in its sports cars, but also in pickup trucks, as well as race cars. However, this wasn’t meant to be forever, as Mazda’s discontinuation of the RX8 in 2012 meant that it no longer makes rotary-powered cars. This decision was guided by some of the critical flaws with rotaries that won’t make them a good choice today. These include their oft-high fuel consumption, as well as the need to constantly maintain it very regularly.

How Many Cylinders Are In A RX7

Since the Mazda RX7 is powered by a rotary engine (the one and only 13B-REW) instead of a piston engine, it doesn’t have cylinders. Instead, its configuration is measured in rotors, not cylinders. In the RX7’s case, it’s a twin-rotor engine. Trying to find a cylinder-based equivalent is rather tricky. However, we know that Wankel rotary engines fire 3 chambers for every revolution. Multiply that by 2 rotors, and it’s sort of the rotary equivalent of a V6. As for its displacement, rotaries are measured the same way as piston engines. In the RX7’s case, each rotor occupies a combustion chamber volume of 652cc. Multiply that by 2 rotors, and you get a total displacement of 1.3-liters. Hence, this is how its engine got its name, the 13B.

Can You Turbo A Rotary Engine

Absolutely! Perhaps the most iconic rotary engine ever, the RX7’s 13B-REW, adopted a ground-breaking and clever sequential turbocharging system. Granted, the later Mazda RX8’s rotary engine was engineered to be a more back-to-basics sports car. Hence, its omission of forced induction. Many hardcore enthusiasts have since modified their RX8s to add a turbocharging system, which certainly improved it in many ways. In fact, one of Mazda’s lead engineers also admitted that rotary engines can benefit greatly from including any form of forced induction. They noted that rotary engines require more low-end torque at lower speeds to best optimize for performance. Thus, adding even a tiny compressor or turbocharger would help a lot.

Do Miatas Have Rotary Engines

Although Mazda has prided itself on its rotary engines, its most popular sports car, the MX-5 Miata, never had one. So, how come? There are several reasons why the small Miata sports car is powered by a conventional inline-4 engine rather than a rotary. Mainly, rotary engines aren’t very practical. They consume a lot of fuel, emit plenty of emissions, and require frequent servicing. This makes it a naturally bad fit for the Miata, which was conceived to be an easy-going, daily driveable, and dependable sports car. Crucially, there’s also the fact that rotary engines only yield the most amount of power at the top-end of the rev range. Again, this is a bad fit for the Miata, where performance should always be readily accessible, even at low speeds, making it a fun car to toss around.

What Is A 4 Rotor Engine

With Mazda and its rotary engines, their configuration and layout aren’t specified in cylinders, as they don’t have any. Due to its distinctive Wankel rotary design, they instead use rotors rather than pistons, which were designed to cycle through their combustion process more efficiently. Typically, most of Mazda’s more contemporary sports and performance cars, like the RX7 and RX8, use 2 rotor engines. Some of their higher-end and rarer offerings, such as the Eunos Cosmo, had a mighty 3 rotor. Meanwhile, the elusive 4 rotor engines are only reserved for Mazda’s most performant vehicles. For example, their world-beating 787B race car was powered by a 28B 4 rotor engine. This was essentially Mazda’s iconic 13B 2 rotor but coupled together into a single engine.